Automatic sealing packaging device

A device and automatic technology, applied in the mechanical field, can solve the problems of low packaging efficiency and achieve the effect of improving packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

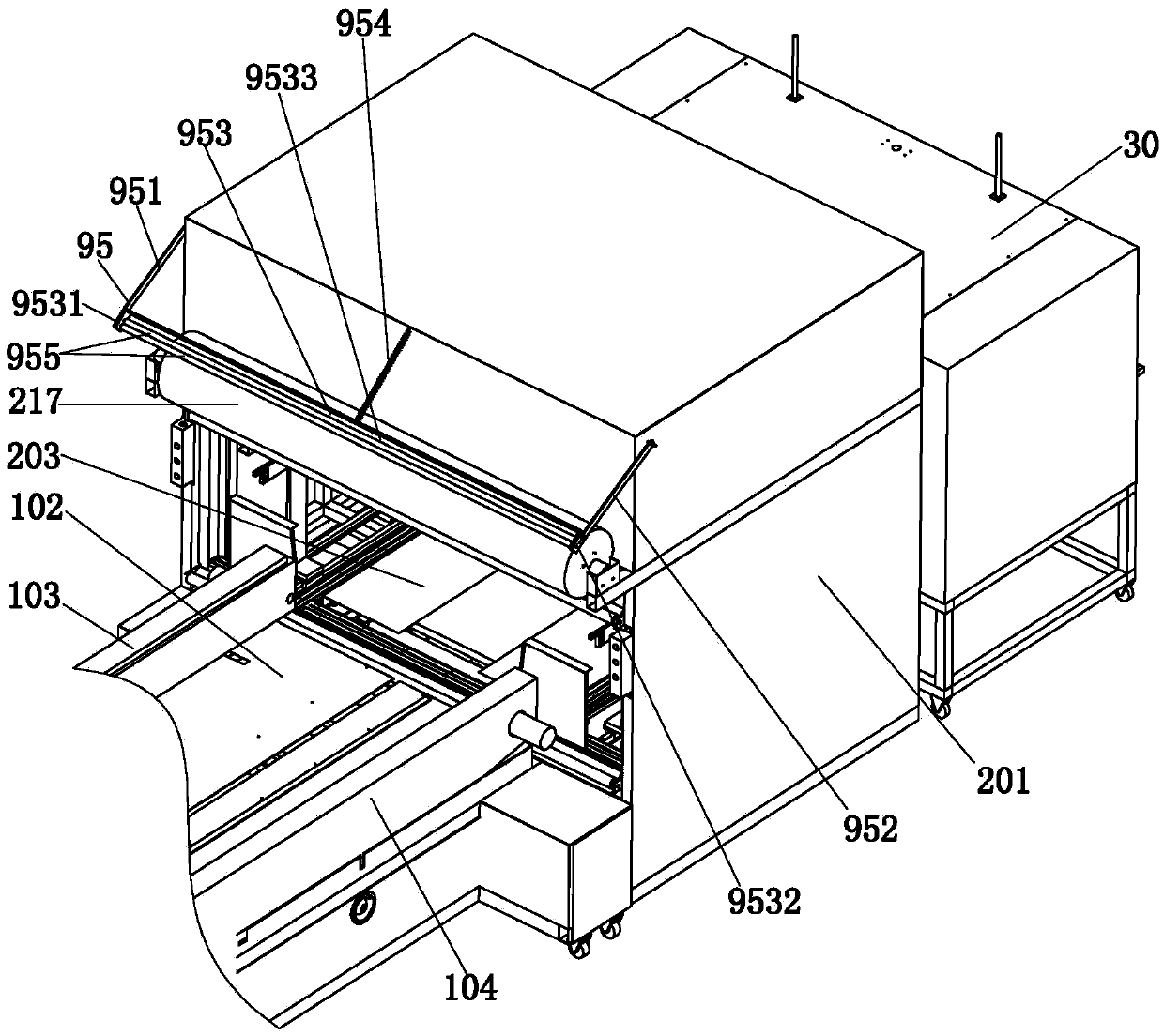

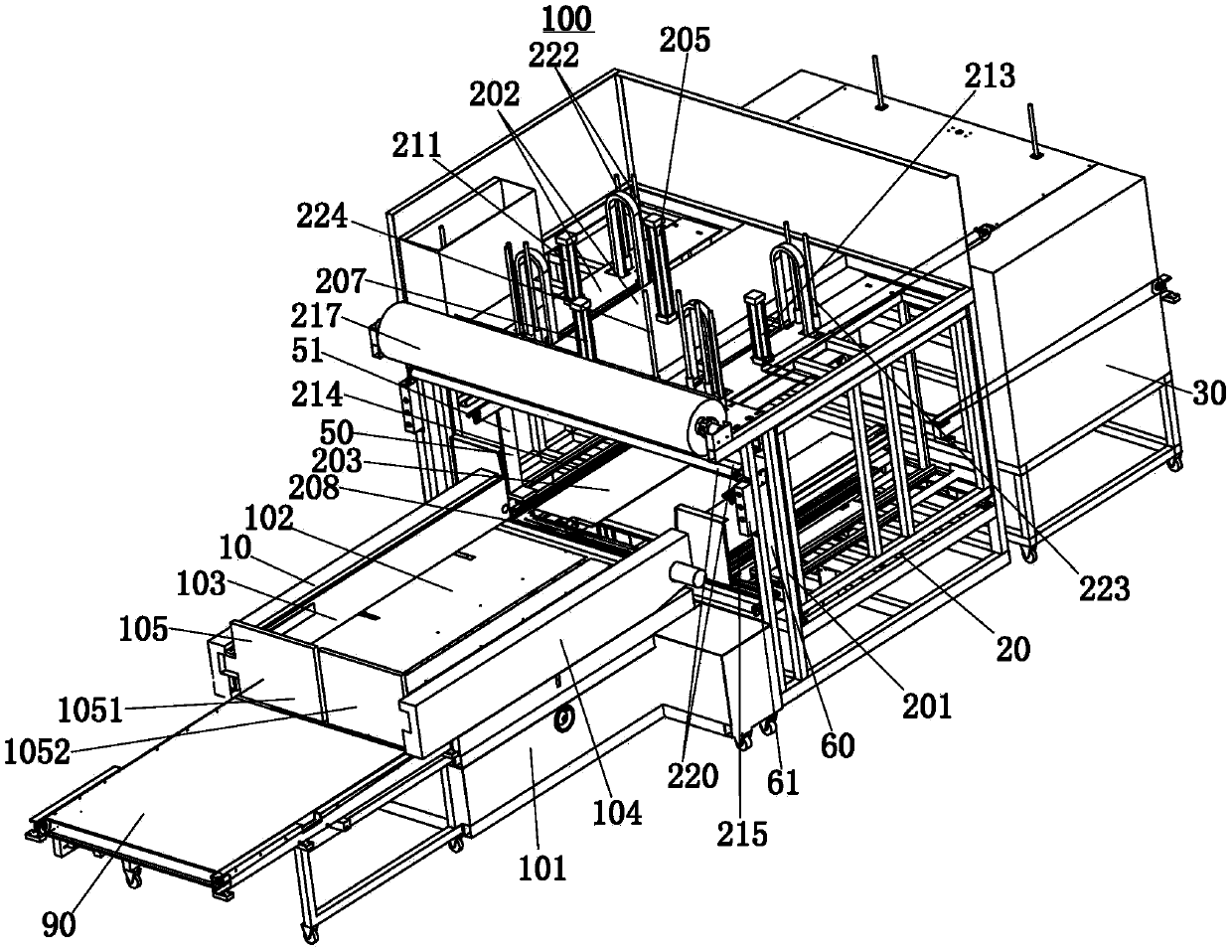

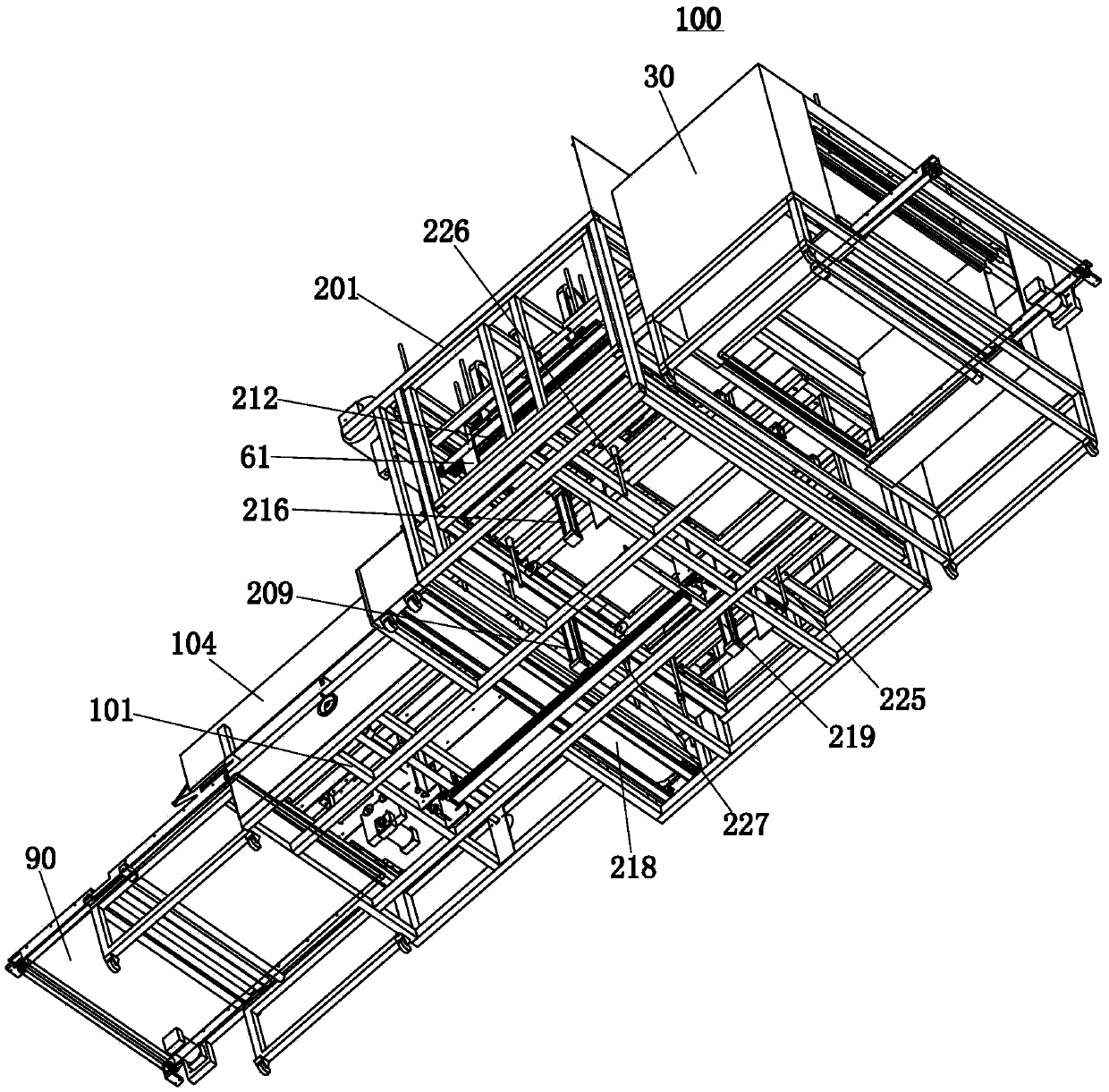

[0018] refer to Figure 1 to Figure 4 , the automatic packaging device 100 of the present invention includes a push feeding mechanism 10, a packaging mechanism 20, a discharging mechanism 30 and a control panel (not shown).

[0019]The packaging mechanism 20 includes a packaging frame 201 through front and back, a top support plate 202, a bottom conveyor belt 203, a lower platen 204, a lower platen cylinder 205, a rear upper hot-melt splint 206, a rear upper cylinder 207, and a rear lower hot-melt splint 208 , Rear lower cylinder 209, left upper hot-melt splint 210, left upper cylinder 211, right upper hot-melt splint 212, right upper cylinder 213, left lower hot-melt splint 214, right lower hot-melt splint 215, right lower cylinder 216, upper packaging film roller 217. The lower packaging film roller 218 and the lower left cylinder 219, the upper packaging film roller 217 and the lower packaging film roller 218 are connected to the upper end and the lower end of the rear part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com