Liquid crystal panel packaging box and forming method thereof

A technology of liquid crystal panel and molding method, which is applied in the field of liquid crystal panel packaging box and its molding, which can solve the problems of difficult to ensure the size of the combined box and increase the difficulty of manufacturing, so as to avoid dimensional instability, improve strength, and improve support strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

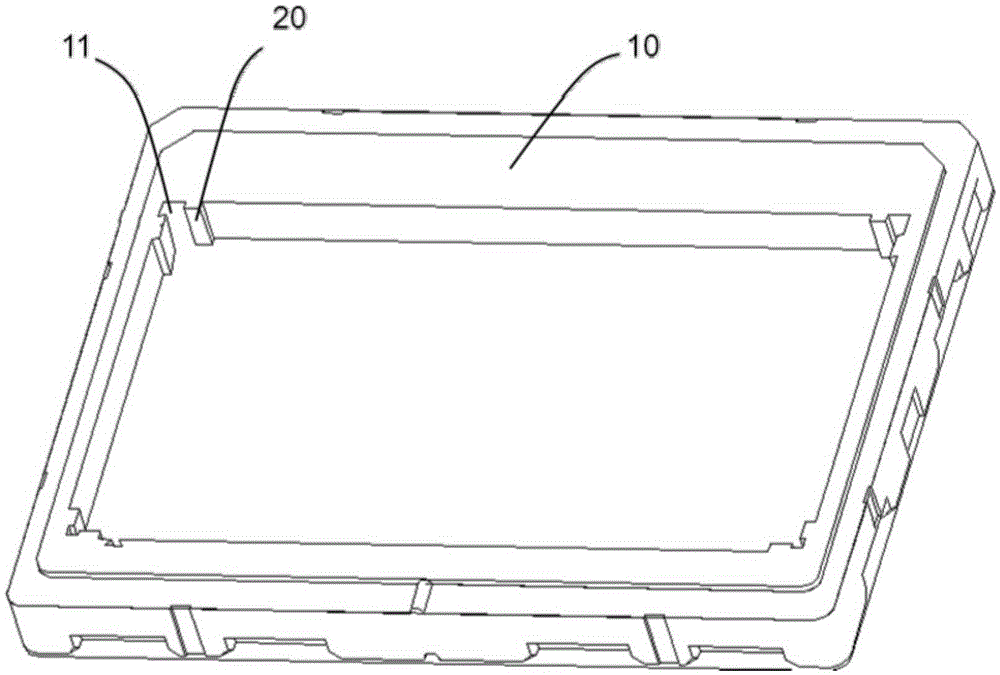

[0021] refer to figure 1 The liquid crystal panel packaging box of this embodiment includes a box body 10 with a slot in the middle and a corner buffer part 20. The corner part buffer part 20 is integrally formed at the four corners of the inner wall of the box body 10 by a foaming process, and protrudes from the The inner wall of the box body 10.

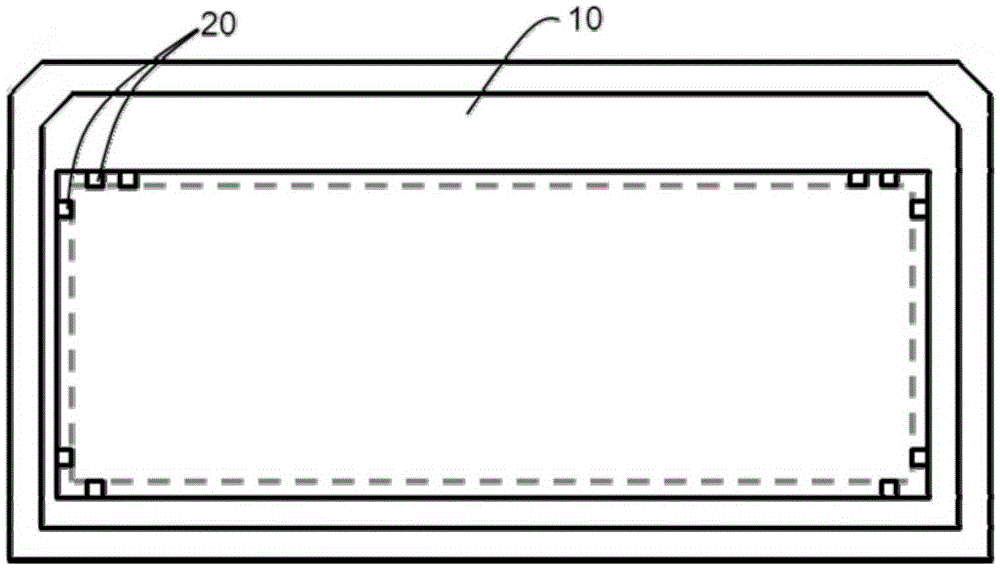

[0022] like figure 2 The end faces of the corner buffers 20 at the four corners of the box body 10 enclose a rectangular area, which is used to elastically contact the four corners of the liquid crystal panel placed therein, and play the role of buffer support and protection.

[0023] In this embodiment, the end surfaces of the corner buffer parts 20 are parallel to the inner wall of the box body 10 , and the side surfaces thereof are perpendicular to the corresponding inner wall of the box body 10 , which is convenient for manufacture. In other embodiments, the side surfaces of the corner buffers 20 can also be inclined relativ...

Embodiment 2

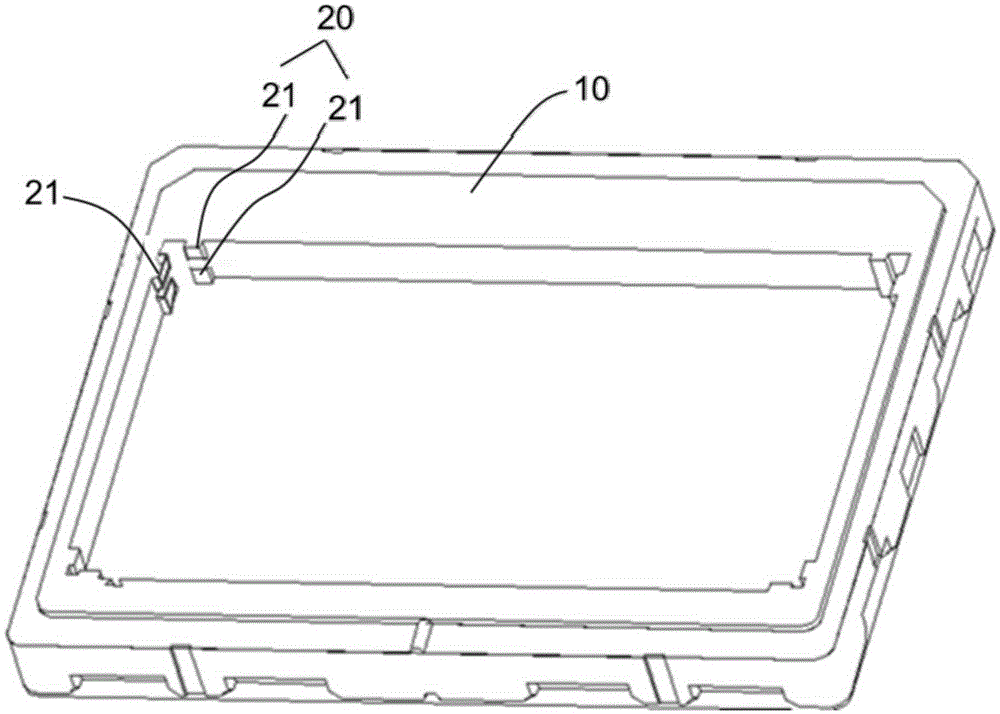

[0029] like image 3 , different from Embodiment 1, at least one corner buffer portion 20 of this embodiment is composed of several sub-buffer portions 21 with the same protrusion height. Each sub-buffer 21 is arranged in a row in the height direction of the box body 10, or may also be arranged in a row in the length direction of the side wall of the box 10, and only a small gap is designed between two adjacent sub-buffers 21, each Each sub-buffer part 21 can allow slight deformation, even if one sub-buffer part 21 is worn or damaged, the adjacent sub-buffer parts 21 can still effectively support and buffer, improving the reliability and service life of the packaging box.

[0030] Due to the composite molding method, the corner buffers are integrally formed at the four corners of the box body, which improves the support strength of the box body, and at the same time avoids the dimensional instability caused by the combined assembly method. In addition, setting the strength of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com