Device and method for turning main equipment automatically through nuclear island ring crane

A main equipment, ring crane technology, applied in the direction of transportation and packaging, load hanging components, walking bridge cranes, etc., can solve the problems of not being on the same center of gravity, the trolley travels too fast, and the trolley does not slide smoothly, etc., to achieve The effect of reducing security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, technical solution and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

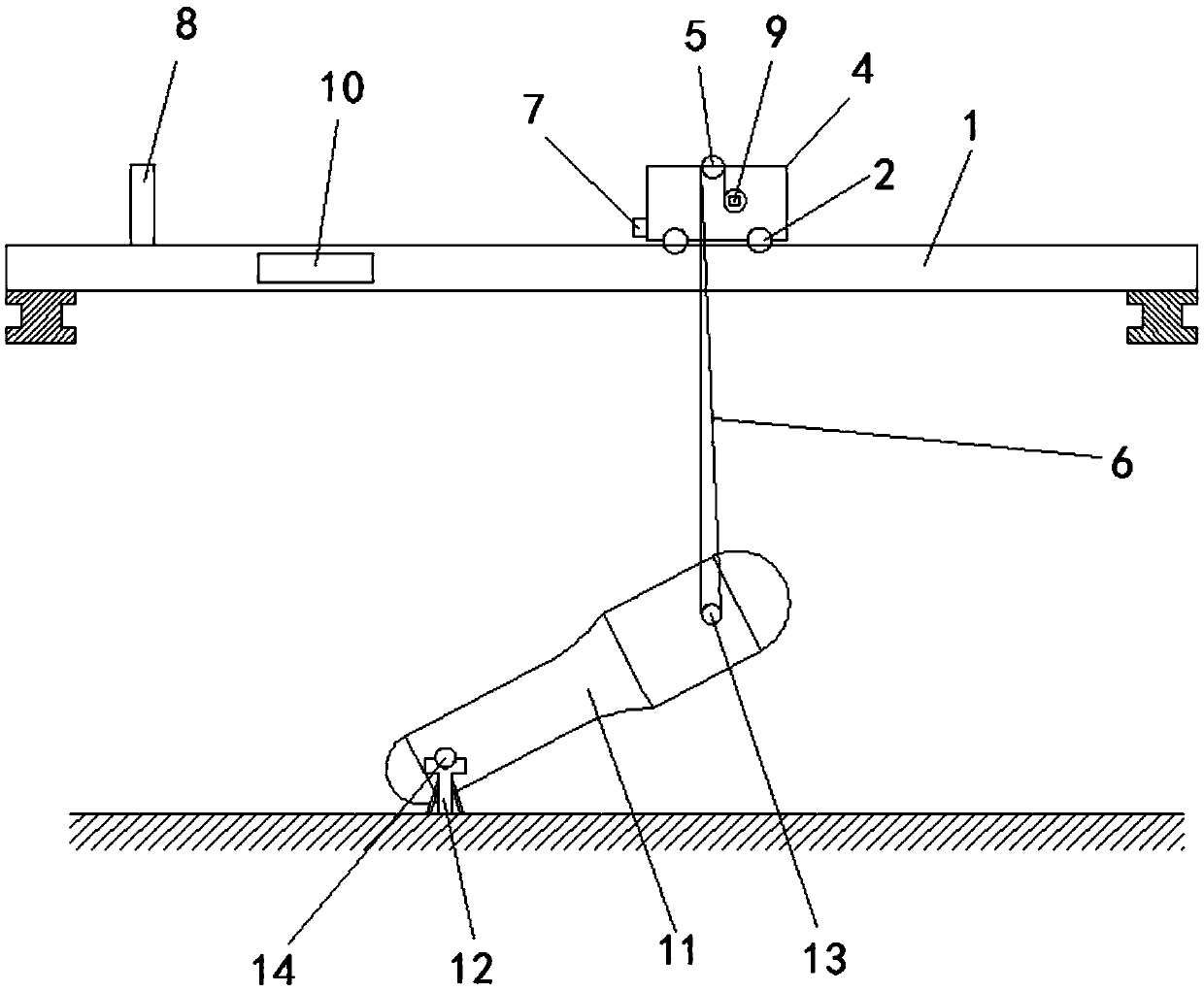

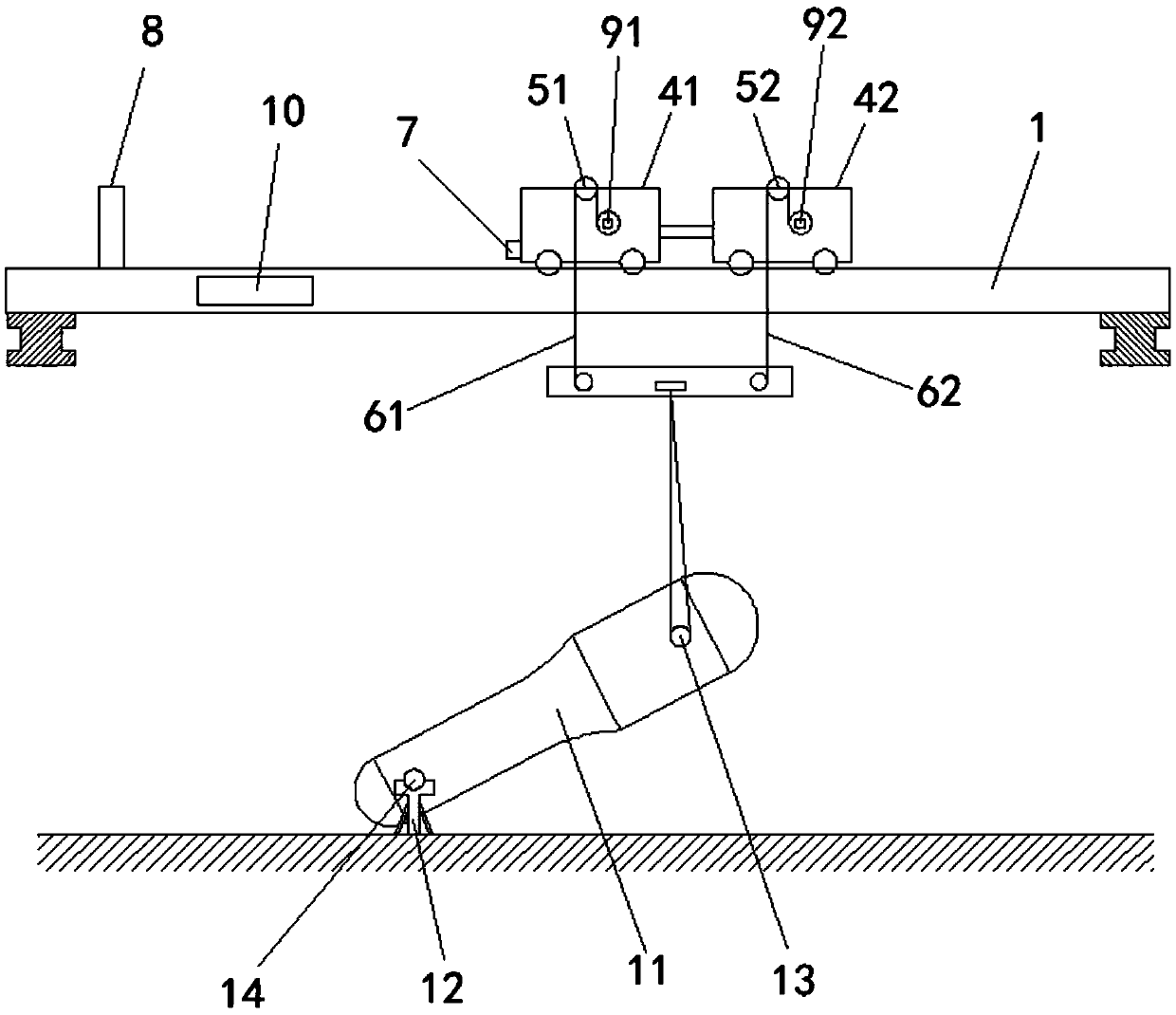

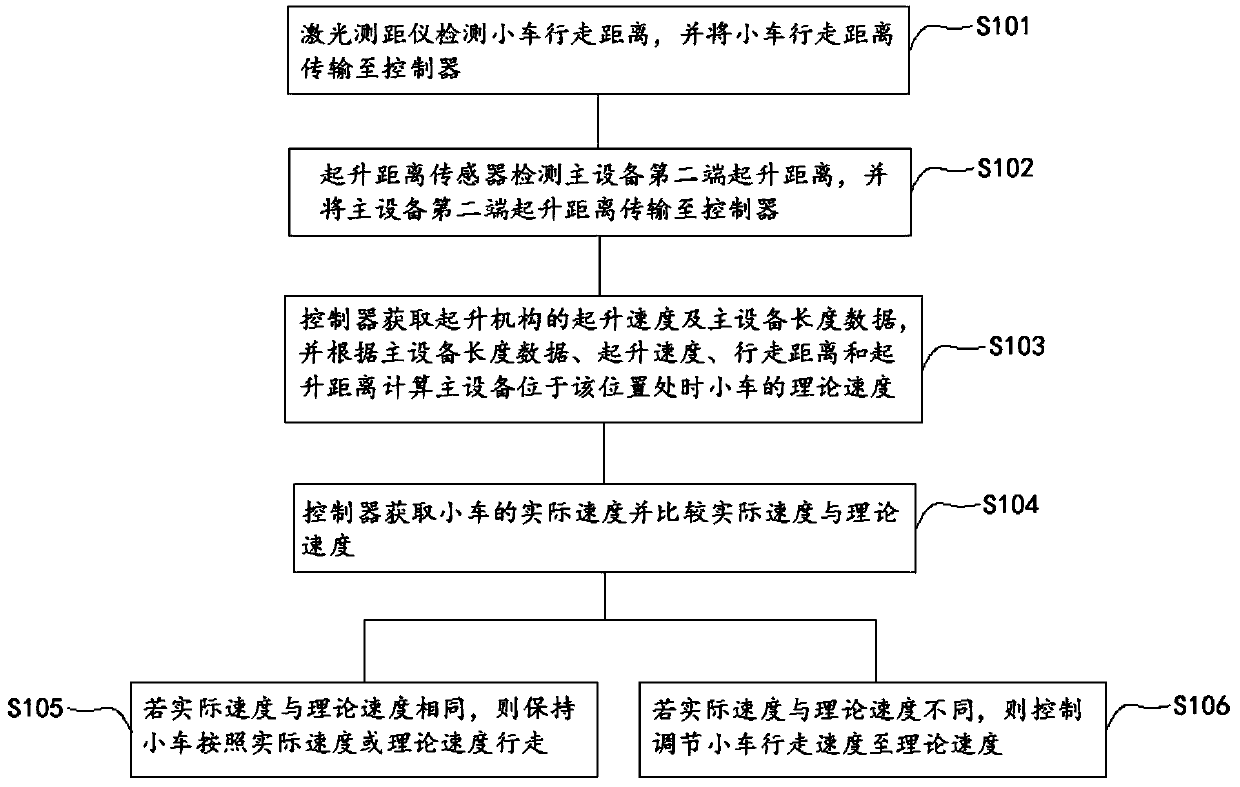

[0027] see figure 1 , figure 1 It is a structural schematic diagram of the first embodiment of the device for automatically turning over the main equipment by nuclear island ring crane in the present invention. In this embodiment, the device for automatically overturning the main equipment using the nuclear island ring crane includes a ring suspension bridge 1, a trolley 4 moving on the ring suspension bridge 1, and a lower end for supporting the main equipment 11 and connecting with the lower end of the main equipment 11. Rotatably connected ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com