Rotary table and engineering machine

A technology of construction machinery and turntable, which is applied in the field of machinery, can solve the problems of local weld seams of bolt fracture, local stress concentration, and potential safety hazards, and achieve the effects of preventing local weld seam cracking, reducing local stress concentration, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

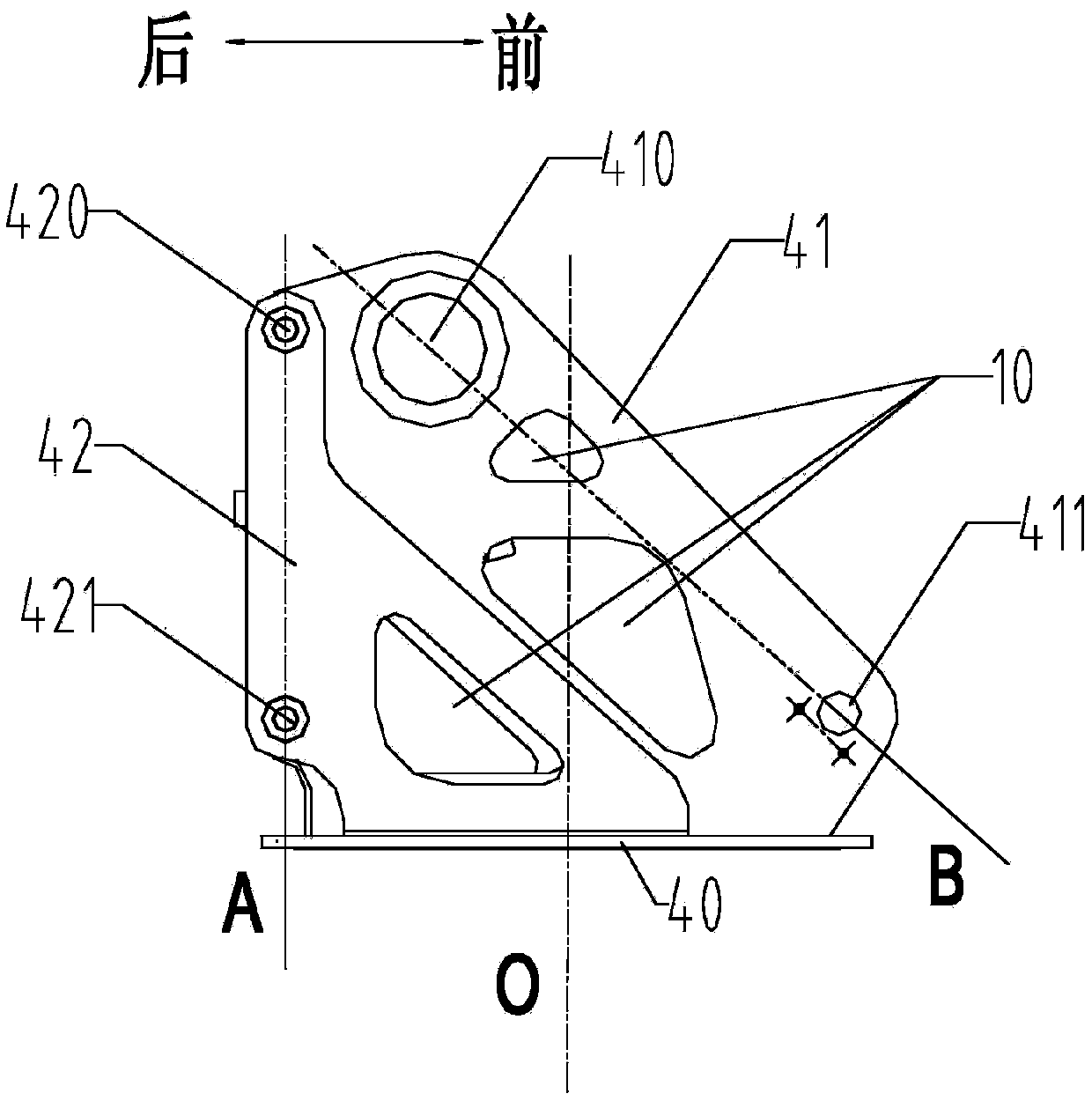

[0021] The front and rear directions described in the present invention are based on the attached figure 1 The anteroposterior orientation shown is described.

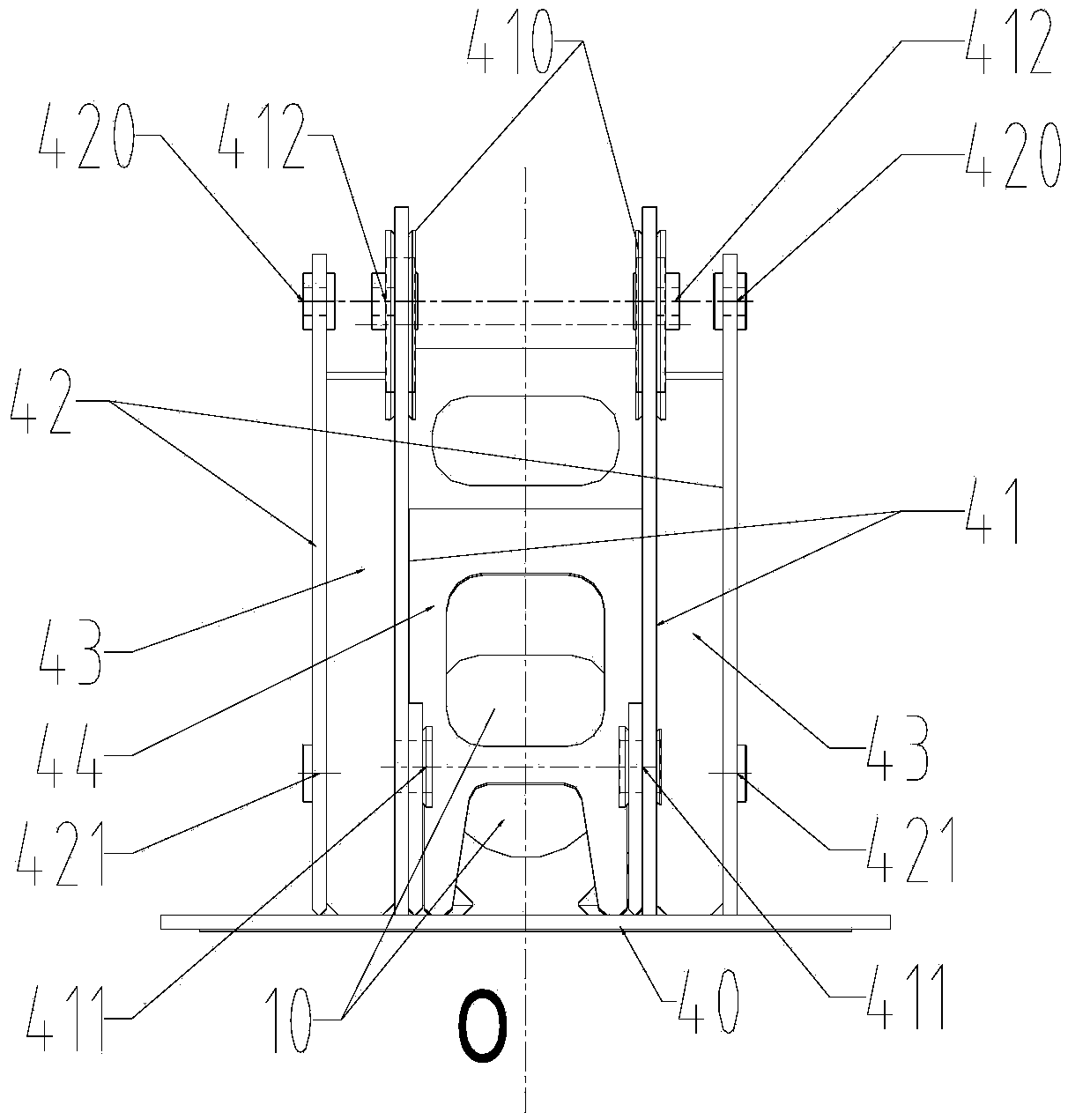

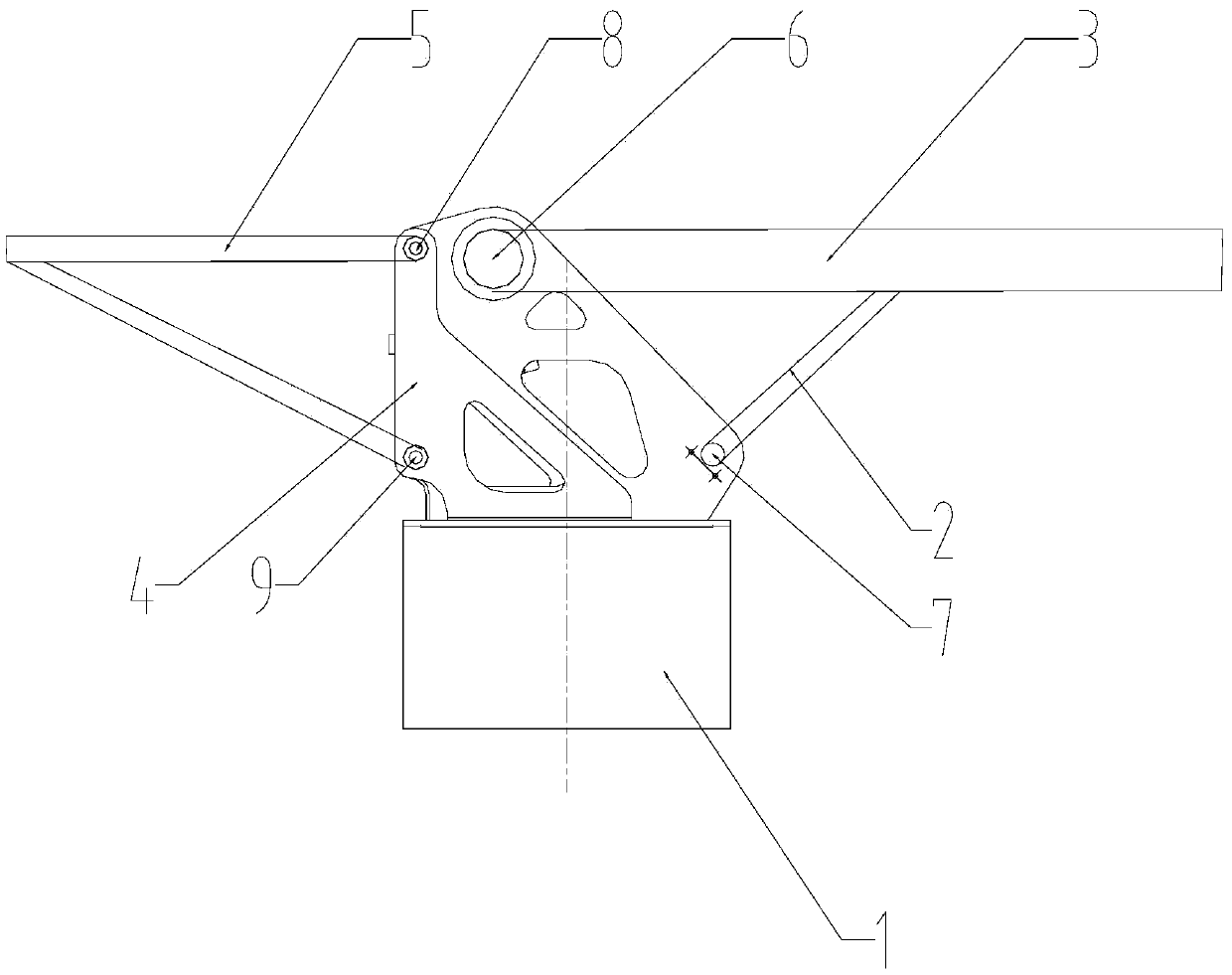

[0022] Combine below Figures 1 to 3 , the preferred embodiment of the present invention is described in further detail,

[0023] Such as figure 1 Shown, the preferred turntable 4 of the present invention (as image 3 Shown), comprising a base plate 40, a first vertical plate 41, a second vertical plate 42, the first vertical plate 41 and the second vertical plate 42 are vertically welded on the base plate 40. A plurality of bolt holes are opened on the bottom plate 40 . A first pin hole 410 and a second pin hole 411 are opened on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com