Biological reactor for enzyme production

A technology of bioreactors and enzymes, which is applied to specific-purpose bioreactors/fermenters, combinations of bioreactors/fermenters, biochemical instruments, etc., can solve problems such as inaccurate water control and poor heat dissipation, and achieve Fine water control, fast heat dissipation and fast fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

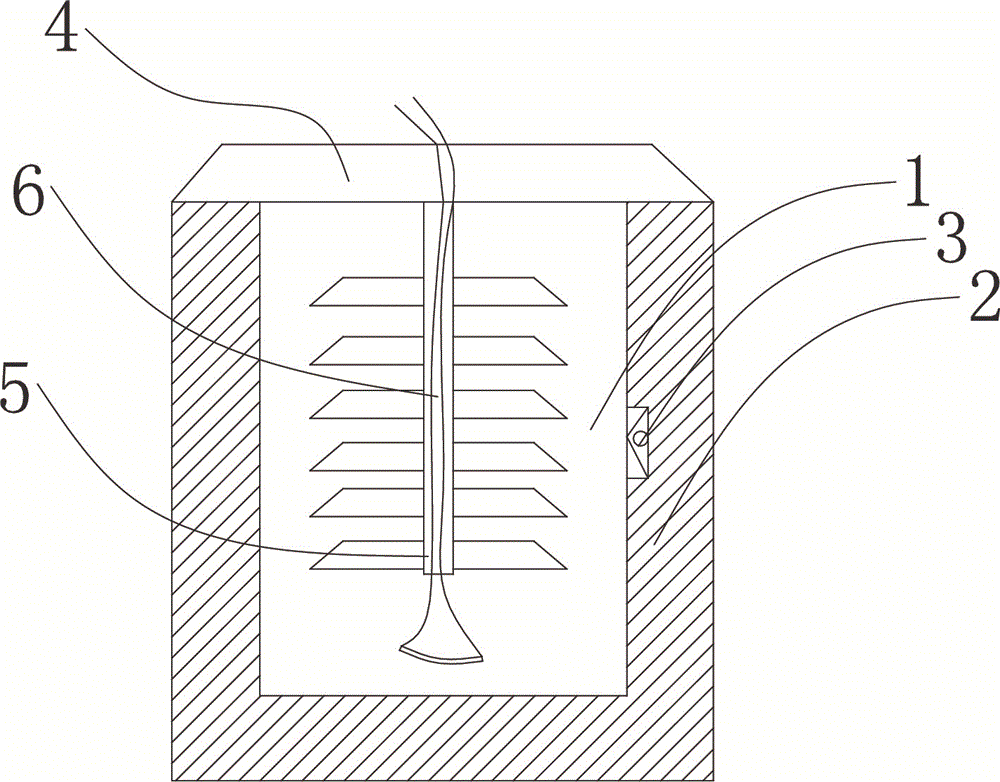

[0014] A bioreactor for ferment production, comprising a fermenter 1, the fermenter 1 is provided with a compartment 2, the compartment 2 is provided with a water inlet, the compartment 2 is connected with the fermenter 1 is provided with a one-way valve 3, the fermentation tank 1 is provided with a stirring rod 5, the stirring rod 5 is provided with blades, and the bottom of the fermentation tank 1 is provided with a weight sensor. The stirring rod 5 is a hollow structure, and a spray pipe 6 is arranged inside, a cover 4 is arranged on the fermentation tank 1, and an exhaust valve is arranged on the fermentation tank 1 .

[0015] When in use, put domestic waste into the fermentation tank 1, wash off oil and salt with water, put it into the separately detachable fermentation tank 3 after filtering, put in special fermentation bacteria (such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com