Rotary hoisting-shaft type mechanical grabbing beam

A rotating and hanging shaft technology, applied in water conservancy projects, artificial waterways, hydroelectric power stations, etc., can solve the problems of cost, complex maintenance, complex mechanical gripping beam structure, complex structure type, etc., and achieve low cost, convenient and fast. Lifting operation, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

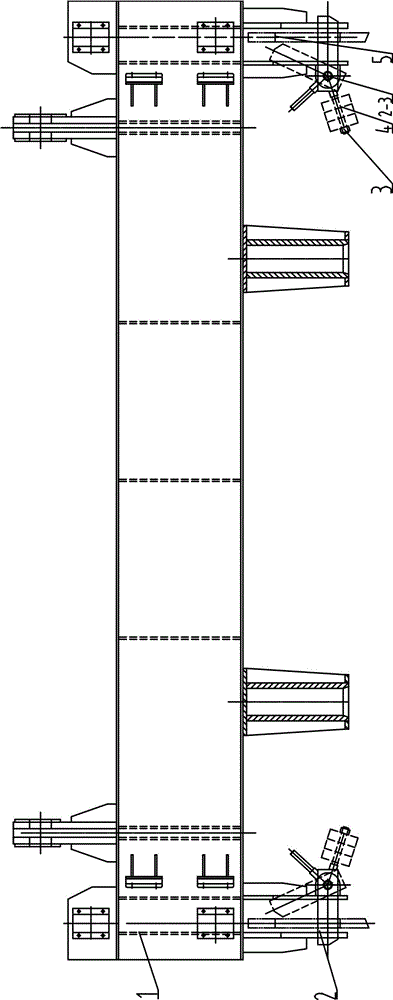

[0015] Such as figure 1 , figure 2 and image 3 As shown, a rotatable hanging shaft type mechanical grabbing beam includes a grabbing beam body 1,

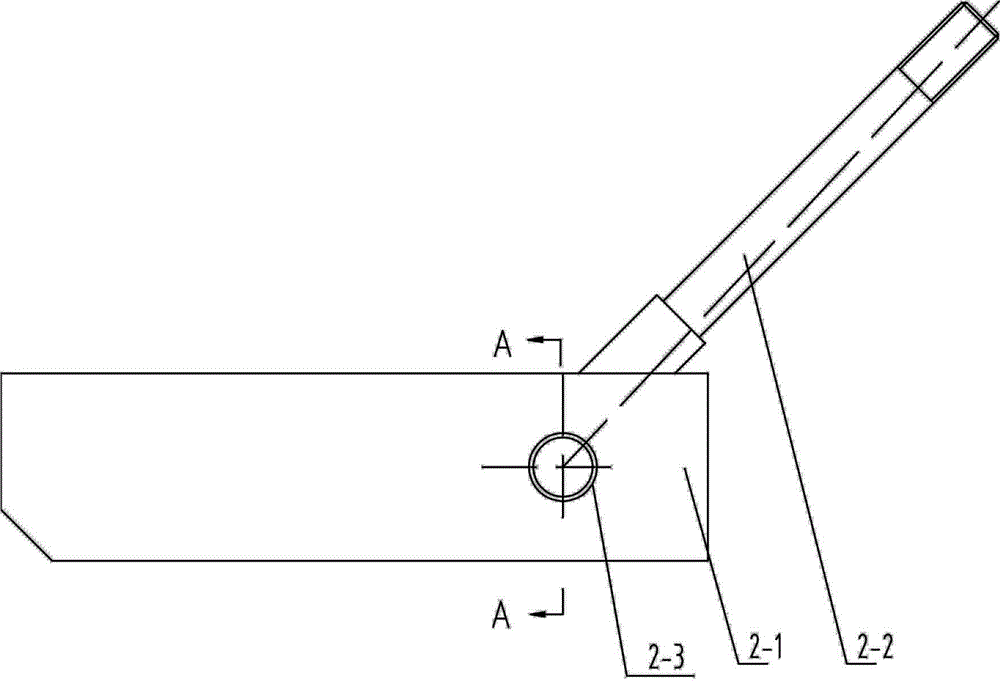

[0016] There are rotatable hanging shafts 2 installed at the 5 places of the lower hanging lug plates and hinged lifting lugs on both sides of the grabbing beam body 1,

[0017] In the rotatable hanging shaft 2, one end of the steel ingot 2-1 is fixedly installed at the hinge lug 5, and the hanging shaft screw 2-2 is rotatably installed on the other end of the steel ingot 2-1 through the hinge pin shaft 2-3;

[0018] After the counterweight 4 is threadedly connected with the suspension shaft screw rod 2-2, it is fixedly installed on the suspension shaft screw rod 2-2 through the lock nut 3;

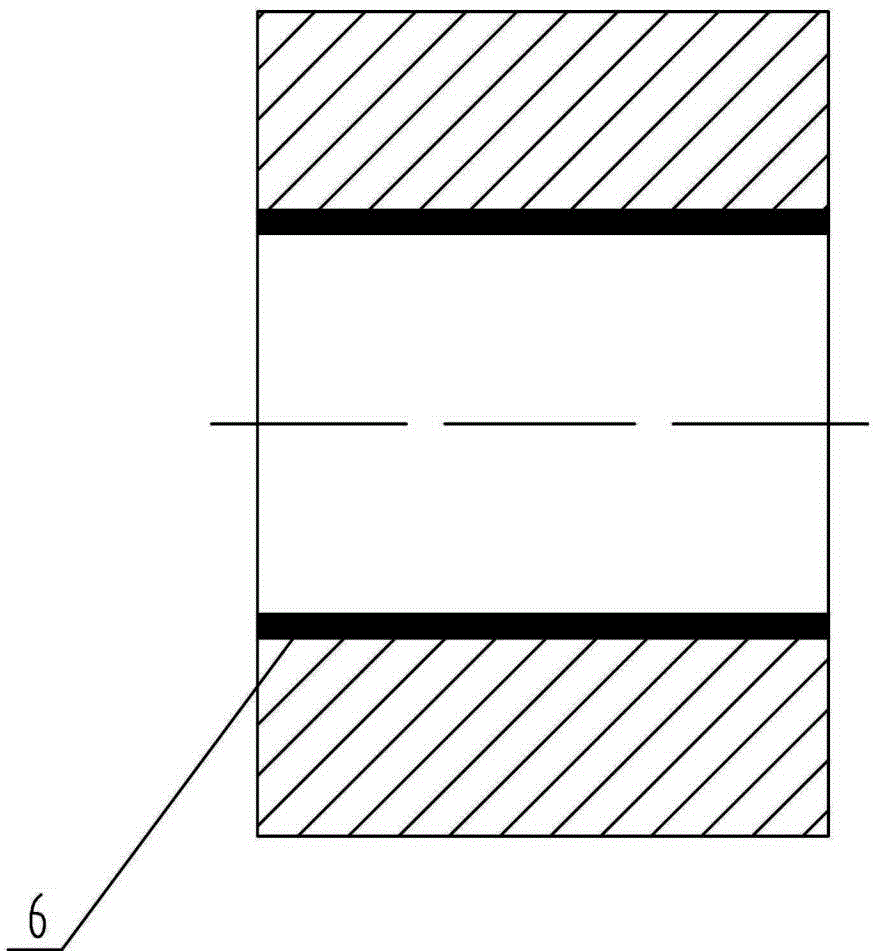

[0019] The suspension shaft screw rod 2-2 is installed in the axle sleeve 6 of the hinge pin shaft 2-3.

[0020] Grasp the opening of the hinge seat end of the lower lug plate under the beam body 1, which is larger than the opening of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com