Flexible coupling

A flexible coupling and shaft hole technology, which is applied in the field of measuring while drilling, can solve the problems that the geometric shape does not meet the requirements and the power requirements, and achieves the effects of continuous and reliable power transmission, simple structure and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

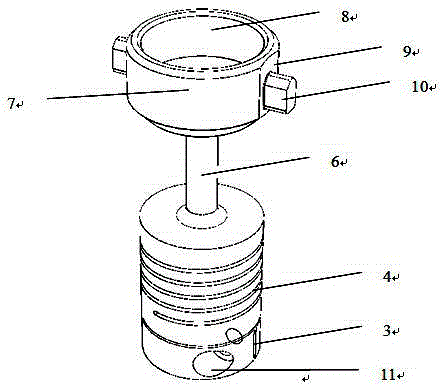

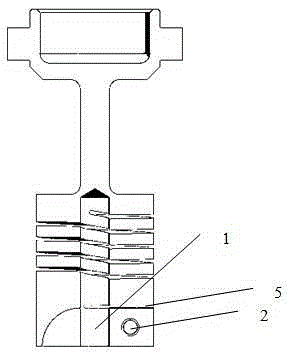

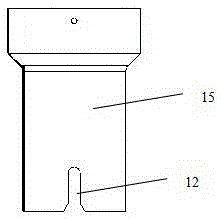

[0029] As a preferred embodiment of the present invention, the present invention discloses a flexible coupling, which includes a part body composed of a rotating body. The part body includes a main body upper part 7, a main body middle part 6 and a main body lower part, and the main body lower part is integrally It is cylindrical, and there is a shaft hole 1 for connecting with the motor output shaft 14 along the axial direction of the lower part of the main body, and a helical cutting groove 4 is opened in the lower part of the main body; The diameters of 7 are greater than the diameter of the middle part 6 of the main body; the upper part 7 of the main body is cup-shaped as a whole, and the side of the upper part 7 of the main body protrudes and is provided with an ear structure 10 coupled with the notch 12 on the coupling part 11, and the top surface of the upper part 7 of the main body A concave hole 8 is provided.

Embodiment 2

[0031] As the best implementation mode of the present invention, on the basis of embodiment 1, refer to the attached figure 1 with 2 , in the radial direction, the depth of the helical cutting groove 4 extends from the surface of the lower part of the cylindrical main body to the shaft hole 1 in the lower part of the main body, and in the axial direction, the helical cutting grooves 4 are arranged in layers. A horizontal cutting groove 5 is provided at the lower part of the spiral cutting groove 4 . The lower part of the main body is provided with a side slit 3, and the outside of the side slit 3 is provided with a threaded hole 2. Two parallel facet structures 9 are arranged on the side of the upper part 7 of the main body, and two ear structures 10 are symmetrically arranged on the facet structures 9 . The main body upper part 7, the main body middle part 6 and the main body lower part are integral molding structures.

[0032] After the motor output shaft 14 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com