Multistage cyclic drying system used for feeding particle aureomycin

A cycle drying and chlortetracycline technology, which is applied to the drying of granular materials, drying of solid materials, drying, etc., can solve the problems of time-consuming and laborious, excessive moisture in semi-finished products, unstable performance, etc., and achieve the advantages of easy installation and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing

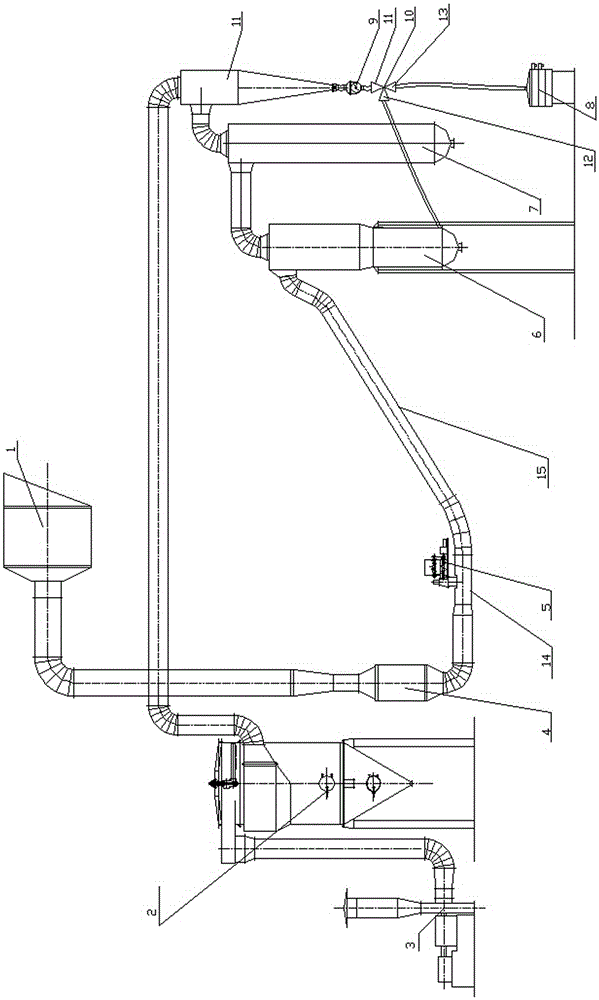

[0019] like figure 1 Shown, the present invention is used for the multistage circulation drying system of aureomycin for feed grain, and it comprises induced draft fan 3, deduster 2, cyclone separator 11, multistage drying mechanism and preheater 4, the above-mentioned several parts The inlet and the outlet are connected through pipelines sequentially, and the inlet of the preheater 4 is also connected with a suction hood 1, and the suction hood 1 and the inlet of the preheater 4 are connected through pipelines, wherein the multi-stage drying mechanism and the preheater The pipeline is called the first pipeline, and the first pipeline is composed of a horizontal pipeline part 14 and an inclined pipeline part 15. A granulator 5 is arranged at the position of the horizontal pipeline part 14, and the outlet of the granulator 5 is connected to the horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com