Aero-engine gas circuit part fault detection method

A technology for aero-engine and gas path components, which is used in engine testing, machine/structural component testing, measuring devices, etc. It can solve problems such as increasing the computational burden and complexity of implementation, and achieve the effect of realizing the fault-tolerant function of the sensor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

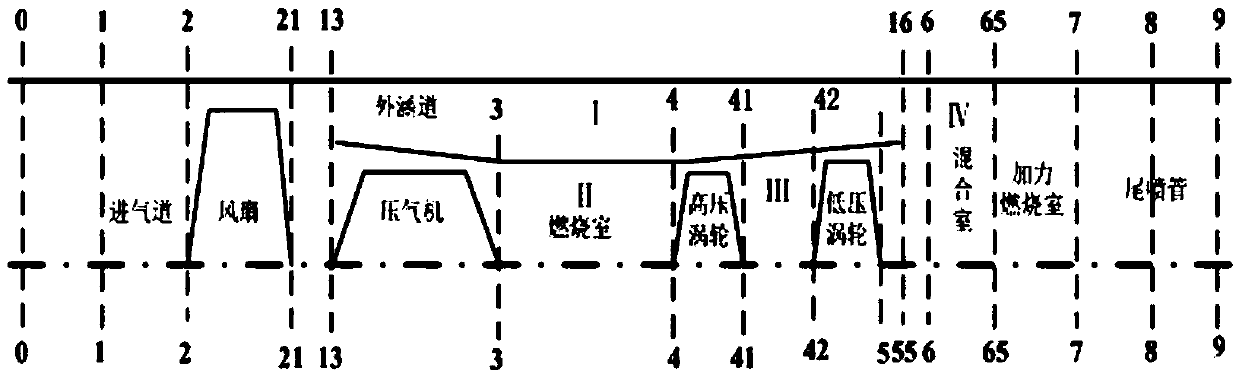

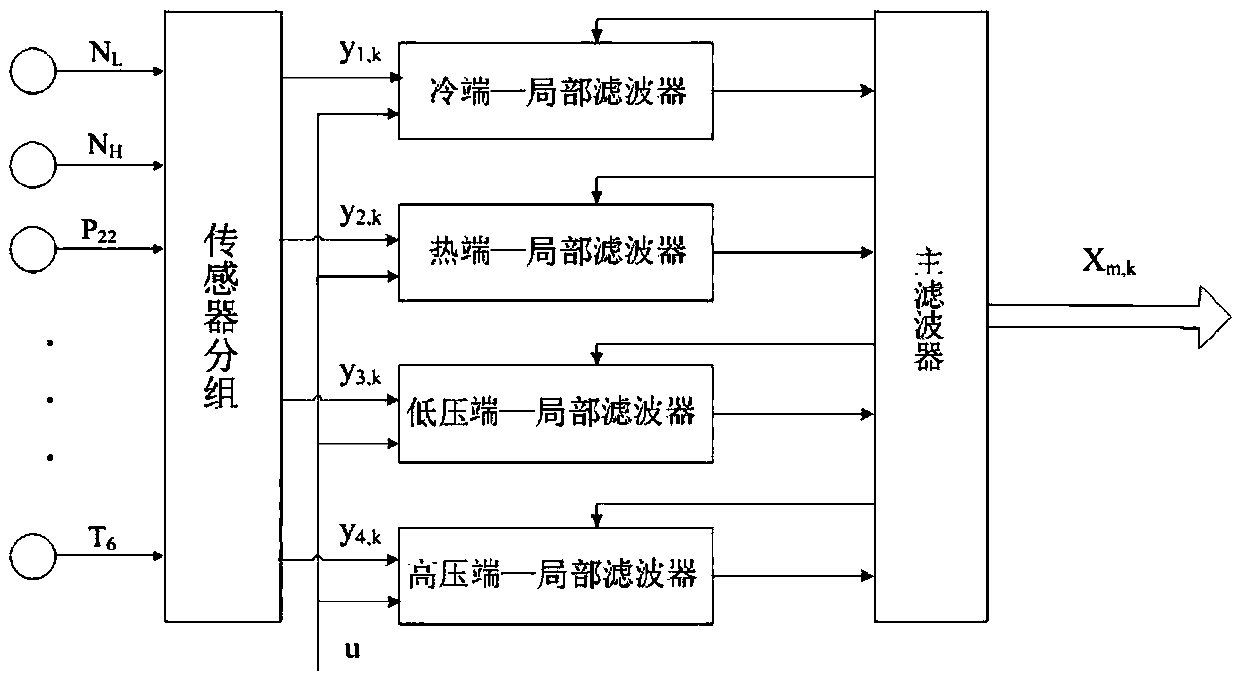

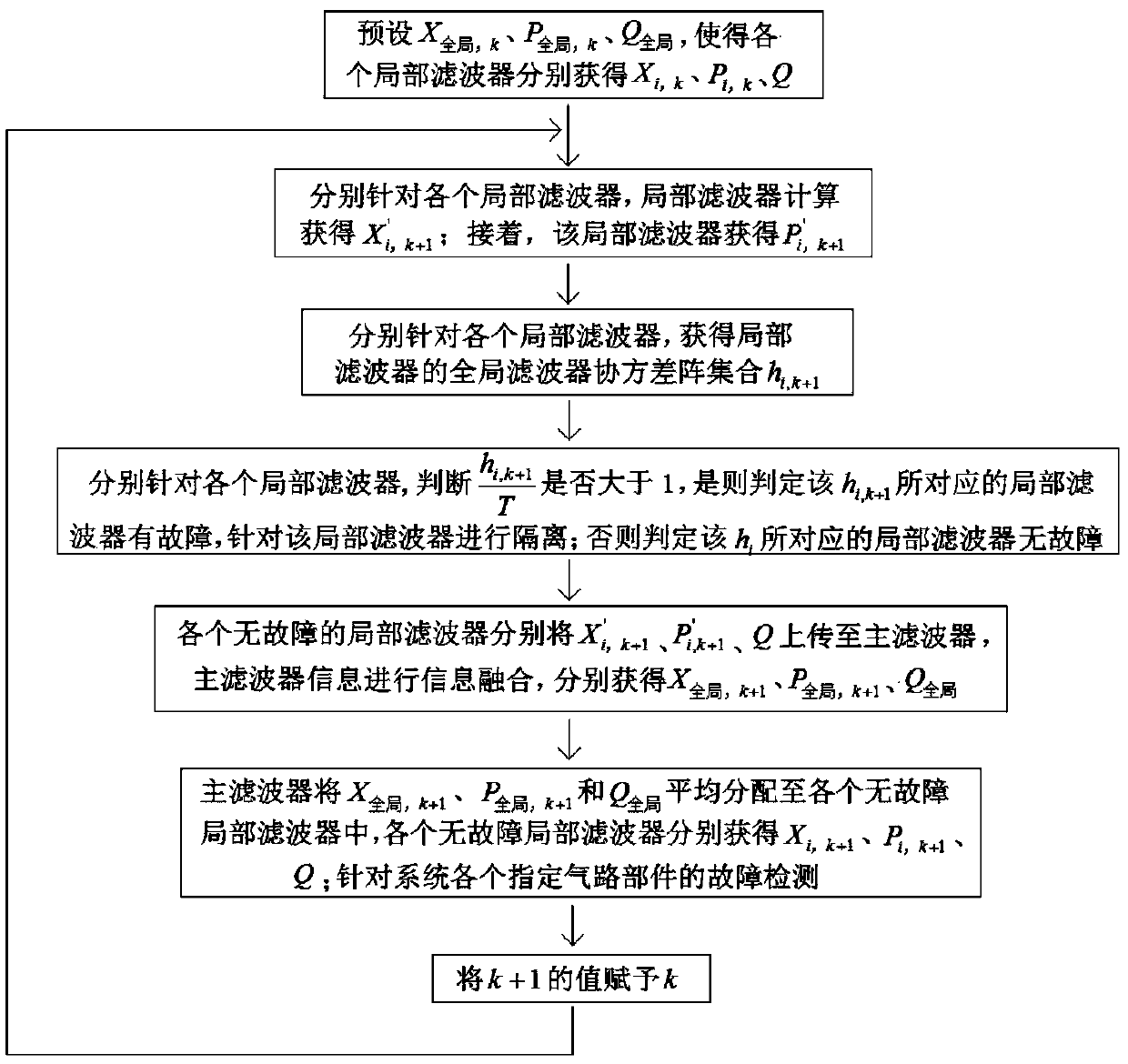

[0043] Since the fused extended Kalman filter is estimated in the form of a filter bank, the redundant information between each sub-filter and the main filter can be used to detect sensor faults, and the estimation results of bad subsystems have great influence on the system fusion solution. The contribution of will be small, and faulty subsystems can be easily isolated, reducing the impact on the global estimate. Therefore, the extended Kalman filter with fusion structure can well complete the fusion diagnosis of aeroengine gas circuit component faults and sensor faults. The working section of the gas path of the turbofan engine involved in the embodiments of the present invention is as follows: figure 1 As shown, the main components include intake duct, fan, compressor, combustion chamber, high-pressure turbine, low-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com