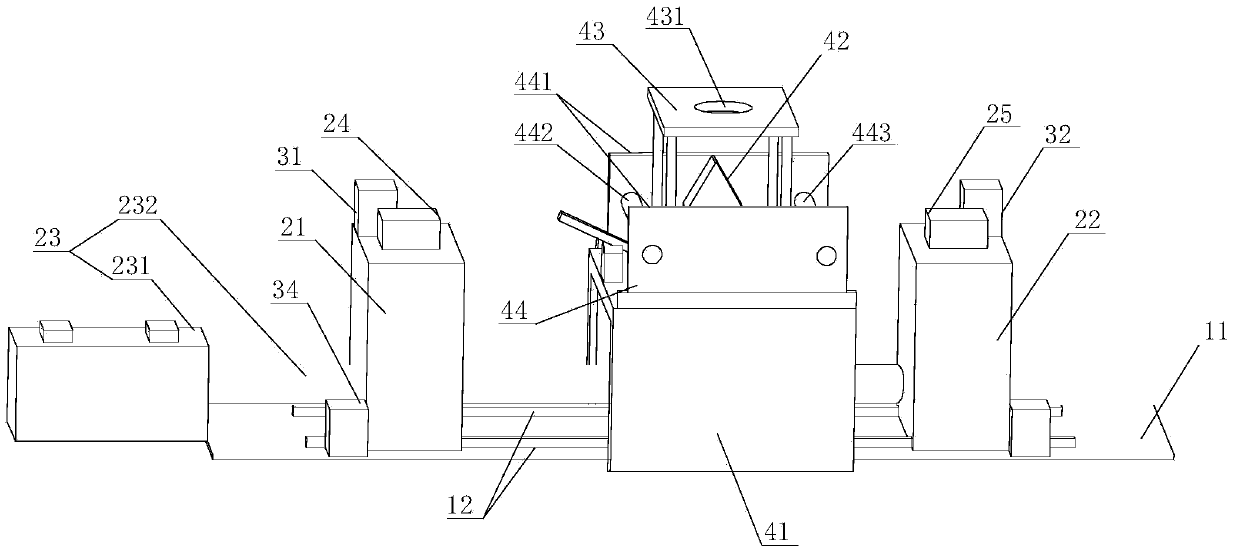

Microstructure observation device applicable to metal material bending deformation

A technology of microstructure and metal materials, applied in measuring devices, using stable bending force to test the strength of materials, analyzing materials, etc., can solve the problem of not being able to test the characteristics of metal microscopic deformation field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

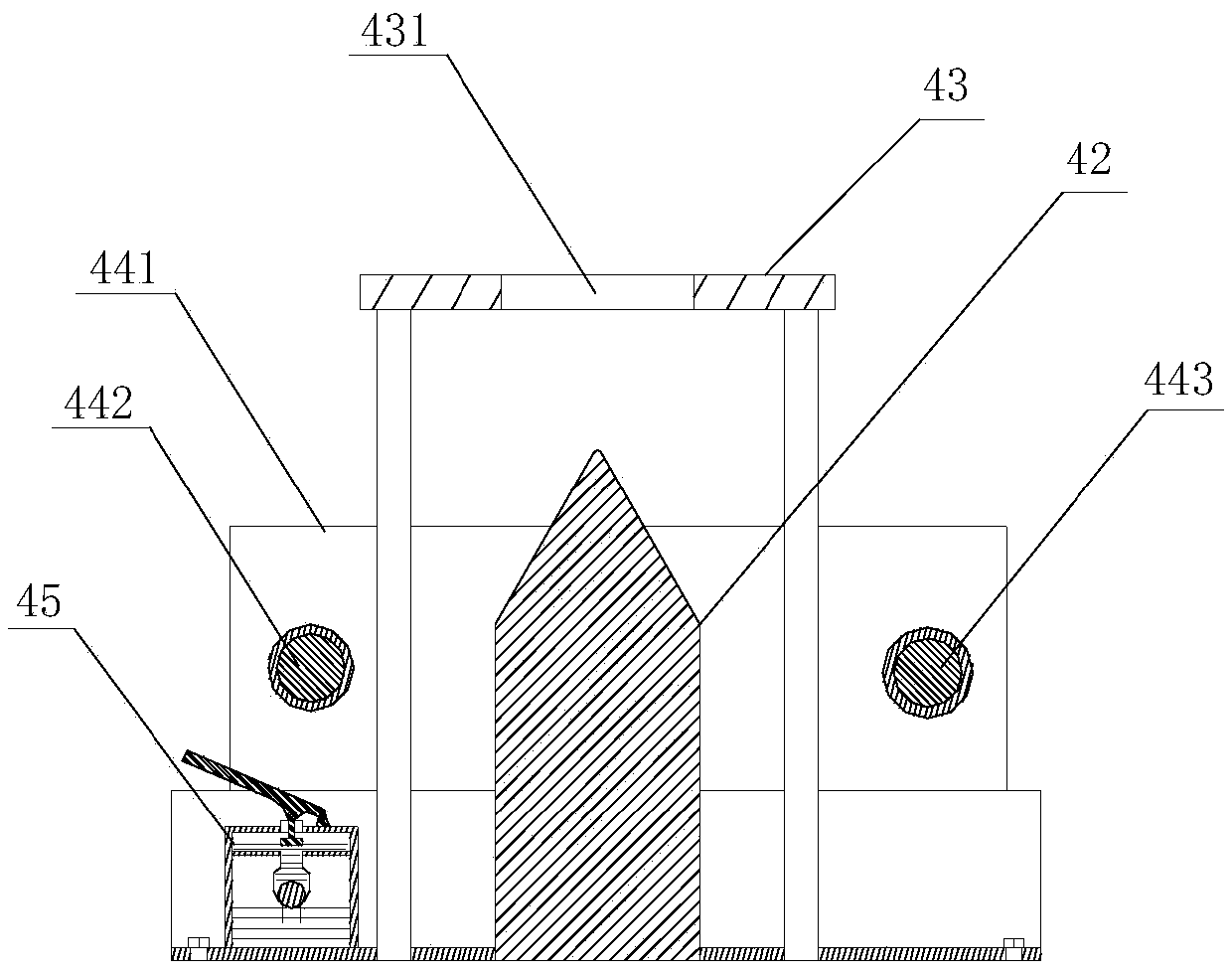

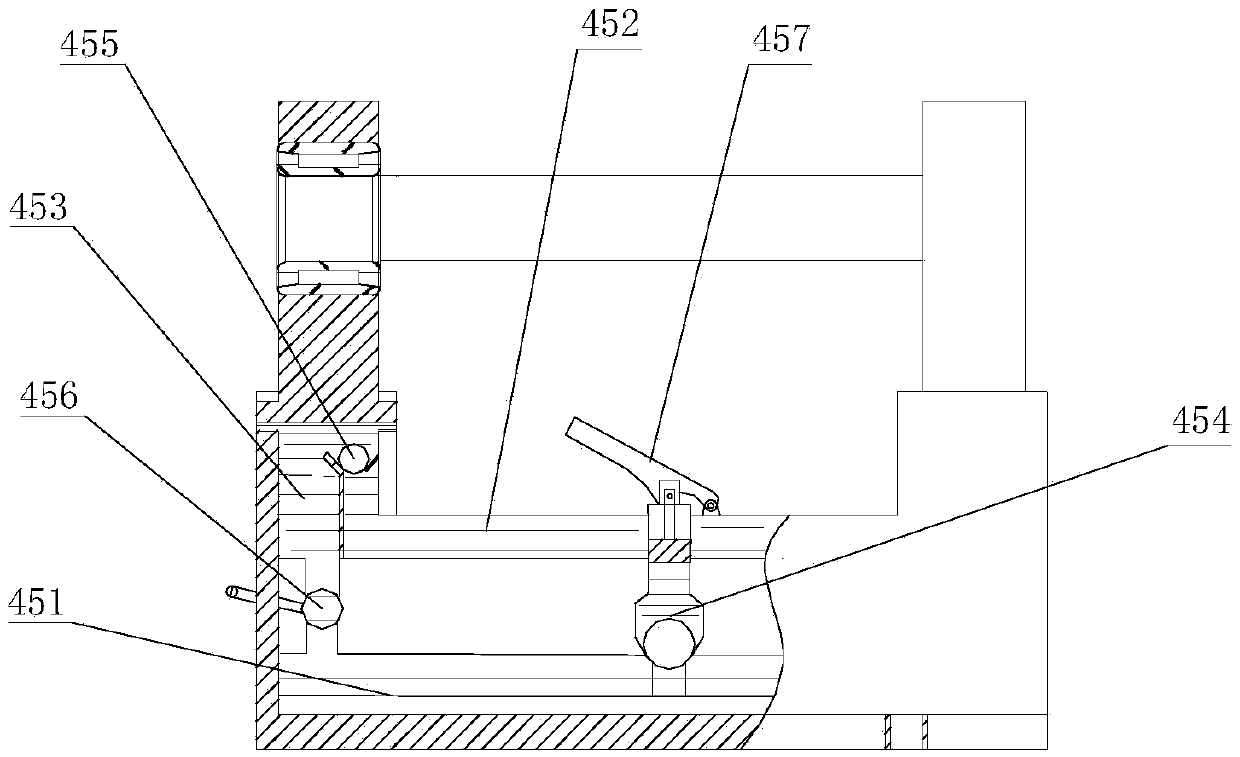

Method used

Image

Examples

Embodiment

[0042] Taking DP590 steel with a thickness of 0.5mm as the research object, the test process specifically includes the following steps:

[0043] 1) Sample preparation: wire cut the DP590 steel plate to 0.5mm or more, then grind it to a thickness of 0.5mm, and use nitric acid alcohol solution for metallographic corrosion.

[0044] 2) Installation of the lifting mechanism: install the lifting mechanism on the top of the door frame-shaped bracket by bolts; then first adjust the rotation wheel 1 and rotation 2 to the initial position through the hydraulic system, that is, the lower edge and the chuck of the rotation wheel 1 and the rotation wheel 2 The clamping surfaces of the first and the second chuck are kept at the same level; then the rotary wheel 1 and the rotary wheel 2 are raised by the hydraulic system until the lower edges of the rotary wheel 1 and the rotary wheel 2 and the installed sample The upper surface is flush; finally, the turning wheel 1 and turning wheel 2 are kept...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com