Shape memorizing polyurethane and preparation method thereof

A polyurethane and polyurethane prepolymer technology, which is applied in the field of shape memory polyurethane and intelligent polymer materials, can solve the problems of restricting wide application, low shape fixation rate and shape recovery rate, and non-cheap raw materials, so as to achieve high efficiency in the synthesis process and preparation The method is easy to operate, and the effect of excellent triple shape memory performance and mechanical tensile performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

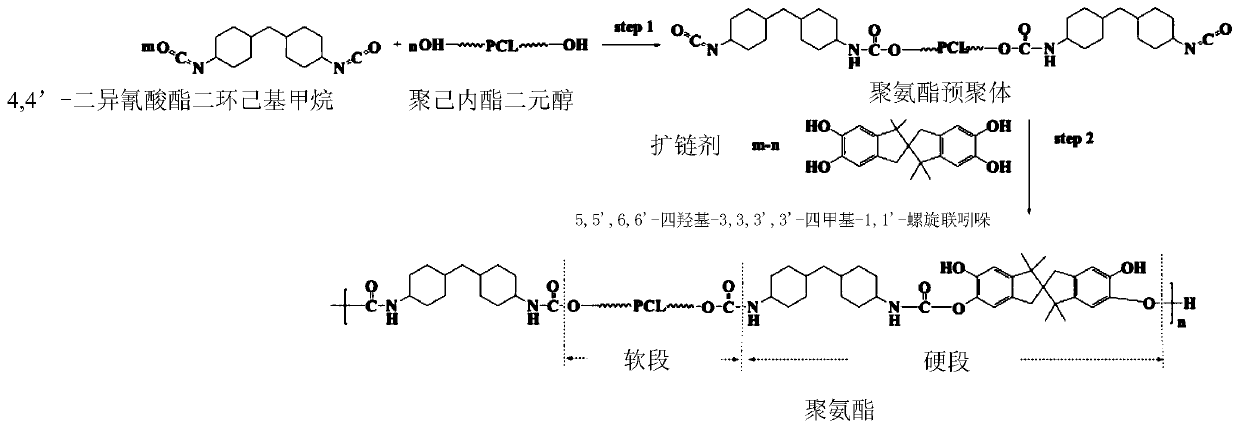

[0021] A method for preparing shape-memory polyurethane provided by an aspect of the embodiments of the present invention includes:

[0022] reacting the first mixed reaction system comprising polycaprolactone diol, diisocyanate, catalyst and organic solvent to prepare a polyurethane prepolymer; and

[0023] The second mixed reaction system comprising the polyurethane prepolymer, the helical non-planar chain extender or the planar chain extender and the organic solvent is reacted, and then the obtained reaction product is solidified to obtain the shape memory polyurethane.

[0024] In some embodiments, the preparation method specifically includes: uniformly mixing polycaprolactone diol, diisocyanate, catalyst, and organic solvent to form a first mixed reaction system, and then microwave reaction at 55-65°C for 30-90 minutes , to prepare the polyurethane prepolymer.

[0025] In some embodiments, the polycaprolactone diol has a weight average molecular weight of 1000-5000.

[...

Embodiment 1

[0047] refer to figure 1 As shown, put 5.00 g of polycaprolactone diol with a molecular weight of 1000 into a round bottom flask, add 2.62 g of dicyclohexyl diisocyanate (HMDI), and then add 20 ml of tetrahydrofuran (THF) and 1% eqv of di Dibutyltin laurate reacted with microwave at 60°C for 45min to obtain a polyurethane prepolymer. The amount of chain extender formula II b added was determined to be 1.36g by acetone-di-n-butylamine titration, and 15ml of N,N-dimethyl Dimethyl formamide (DMF), microwaved at 70°C for 60min, and finally poured into a mold preheated at 80°C, cured in a vacuum oven at 80°C for 16h, and the shape memory polyurethane (marked as polyurethane PU-1) was obtained , and its performance test results are shown in Table 1.

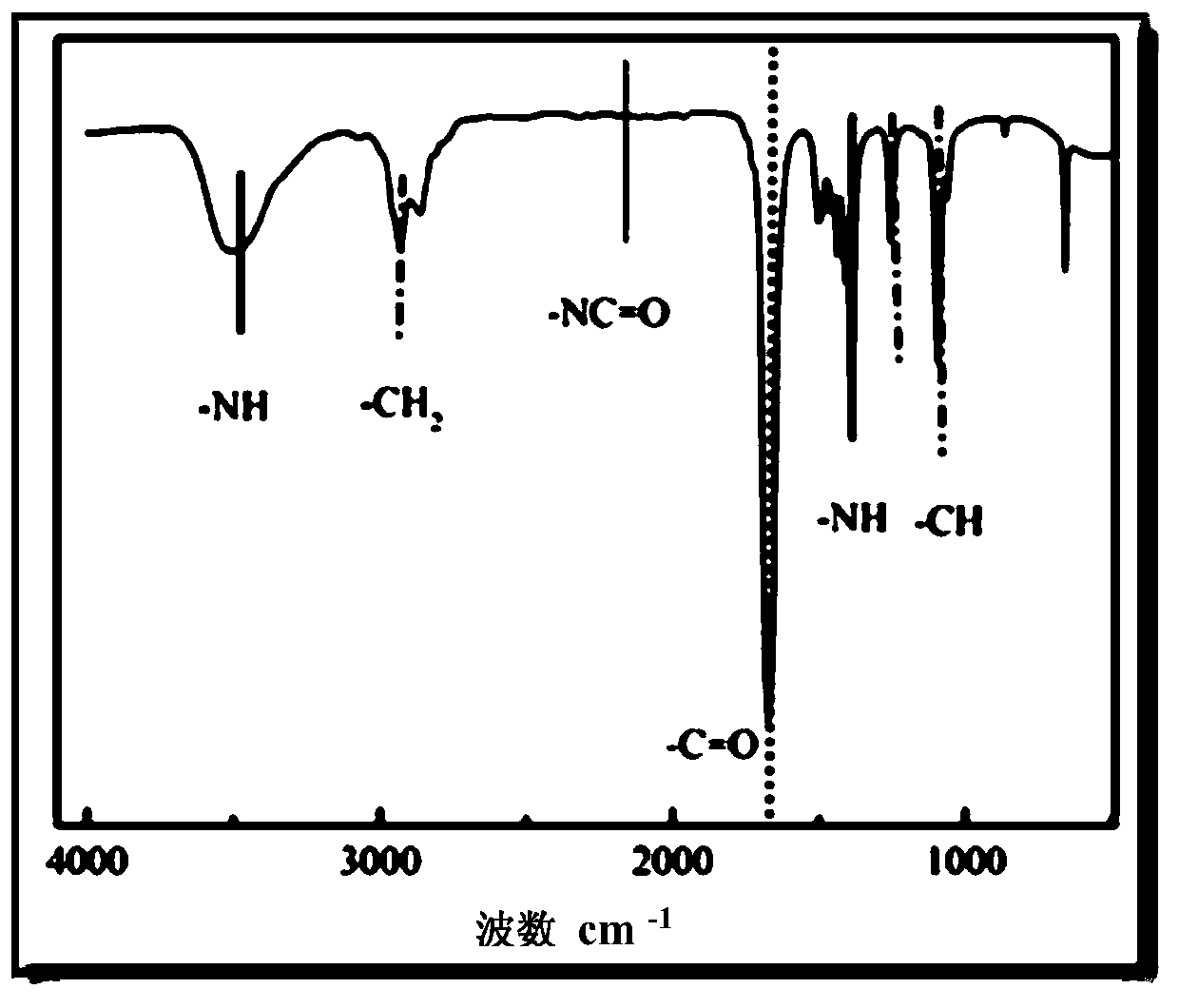

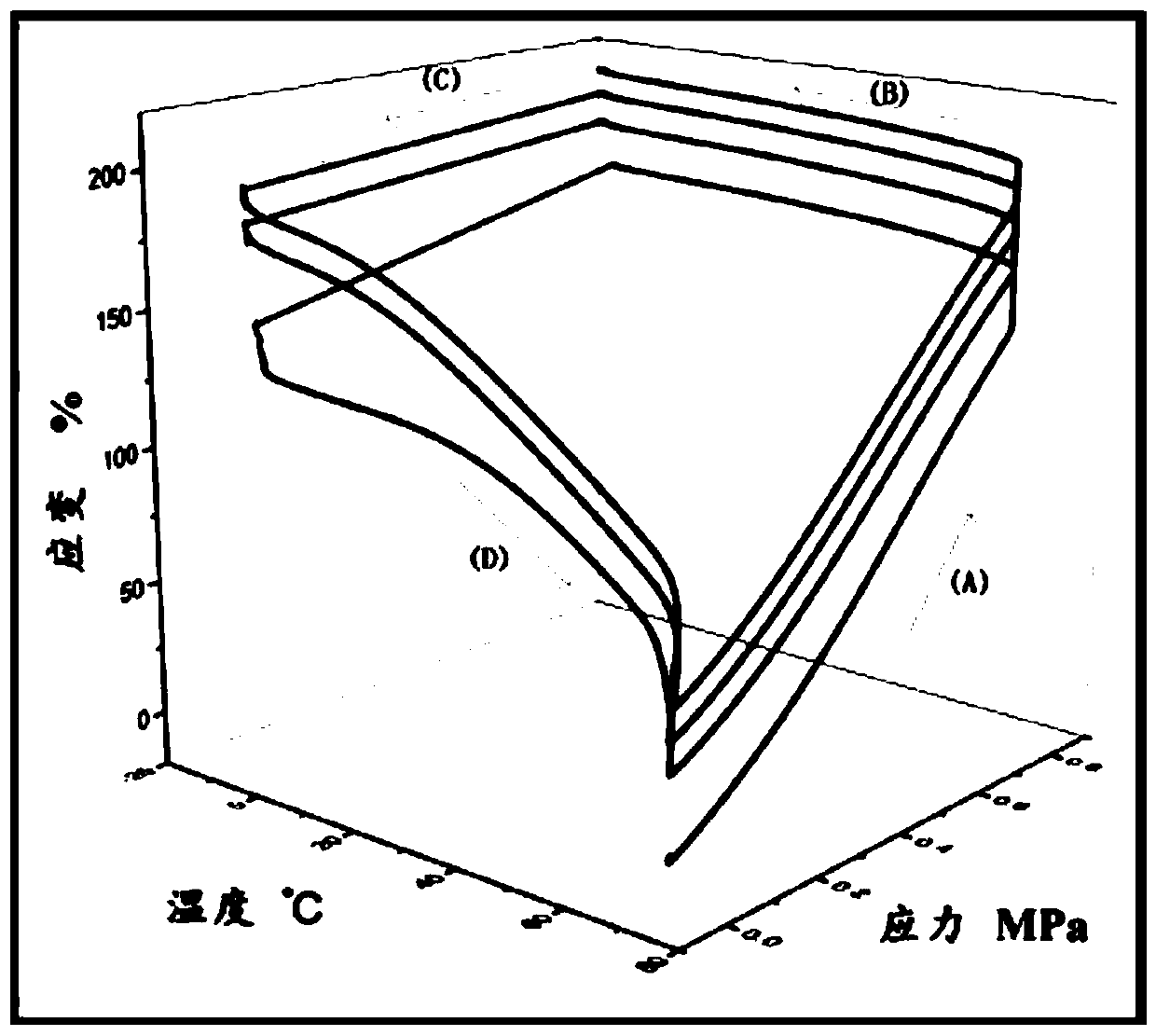

[0048] Please refer to the FT-IR figure of the shape memory polyurethane obtained in this embodiment figure 2 , the shape memory curve (DMA) diagram see image 3 .

Embodiment 2

[0050] Put 5.00g of polycaprolactone diol with a molecular weight of 1000 into a round bottom flask, add 2.50g of diphenylmethane diisocyanate (MDI), and then add 20ml of dichloroethane and 1% eqv of dilauric acid Dibutyltin reacted with microwave at 60°C for 45 minutes to obtain a prepolymer of polyurethane. The acetone-di-n-butylamine titration method determined that the amount of chain extender formula II b added was 1.38 g, and 15 ml of N,N-dimethylformaldehyde was added Amide (DMF), microwaved at 70°C for 60min, and finally poured into a mold preheated at 60°C, cured in a vacuum oven at 80°C for 14h, and the shape memory polyurethane (marked as polyurethane PU-2) was obtained. The performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com