Triple shape memory cyanate ester and preparation method thereof

A technology of cyanate ester and cyanate ester prepolymer, which is applied in the field of shape memory polymer synthesis, can solve the problems of limiting the types of optional resins, the separation of glass transition peaks is not obvious, and the glass transition temperature range of resin is narrow. Triple shape memory performance, achieve selective shape recovery, achieve selective drive deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

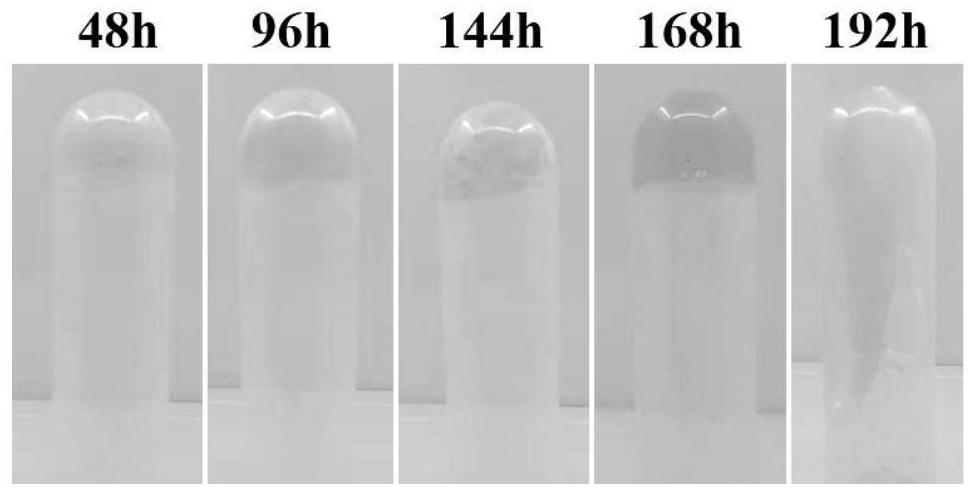

[0040] Optionally, the preparation method of the cyanate ester prepolymer includes: dissolving the cyanate ester monomer at 110-120° C., then heating and stirring continuously for 180-220 h, and cooling to room temperature to prepare the cyanate ester monomer. ester prepolymer. figure 1 The morphology of the cyanate ester prepolymer at different heating times is shown.

[0041] Optionally, the cyanate monomer is bisphenol A cyanate.

[0042] Optionally, the epoxy resin is selected from one or more of bisphenol A epoxy resin, bisphenol F epoxy resin, cyanuric epoxy resin, novolac epoxy resin and hydantoin epoxy resin .

[0043] Optionally, the epoxy acrylate is selected from bisphenol A epoxy acrylate, bisphenol F epoxy acrylate, cyanuric epoxy acrylate, novolac epoxy acrylate and hydantoin epoxy acrylate one or more of.

[0044] Optionally, the acrylate is selected from polyethylene glycol diacrylate, polypropylene glycol diacrylate, neopentyl glycol diacrylate, dipropylen...

Embodiment 1

[0054] A triple shape memory cyanate ester, comprising in parts by weight: 30 parts of cyanate ester prepolymer, 15 parts of bisphenol A epoxy resin, 20 parts of bisphenol A epoxy acrylate, 30 parts of polyethylene glycol diacrylic acid ester, 5 parts of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide;

[0055] The preparation method includes the following steps:

[0056] S1. Preparation of printable ink: by weight, mix cyanate ester prepolymer, epoxy resin, epoxy acrylate, acrylate and photoinitiator uniformly to prepare printable ink;

[0057] Wherein, the preparation method of the cyanate ester prepolymer includes: dissolving the cyanate ester monomer at 120° C., then magnetically stirring slowly, continuously heating and stirring for 192 hours, and cooling to room temperature;

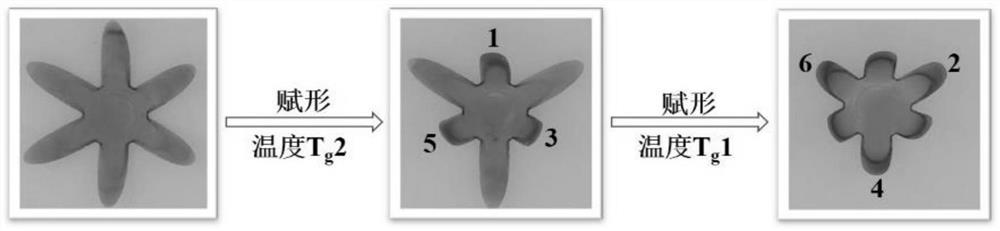

[0058] S2, light-curing printing and molding: using a light-curing printer to print the printable ink, in this example, a six-petal flower structure is obtained by printing;

[0059] S3. Construct...

Embodiment 2

[0065] A triple shape memory cyanate ester, comprising in parts by weight: 40 parts of cyanate ester prepolymer, 10 parts of bisphenol A epoxy resin, 15 parts of bisphenol A epoxy acrylate, 30 parts of trimethylolpropane triglyceride Acrylate, 5 parts of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide;

[0066] The preparation method includes the following steps:

[0067] S1. Preparation of printable ink: by weight, mix cyanate ester prepolymer, epoxy resin, epoxy acrylate, acrylate and photoinitiator uniformly to prepare printable ink;

[0068] Wherein, the preparation method of the cyanate ester prepolymer includes: dissolving the cyanate ester monomer at 120° C., then magnetically stirring slowly, continuously heating and stirring for 192 hours, and cooling to room temperature;

[0069] S2, light-curing printing and forming: using a light-curing printer to print the printable ink;

[0070] S3. Constructing an interpenetrating network: the printed object is irradiated with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com