Concrete cracking overall process testing device based on true environment

A technology of concrete cracking and testing device, which is applied in the field of concrete cracking whole process test, test device, and cracking whole process simulation test, to achieve the effect of ensuring accuracy and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

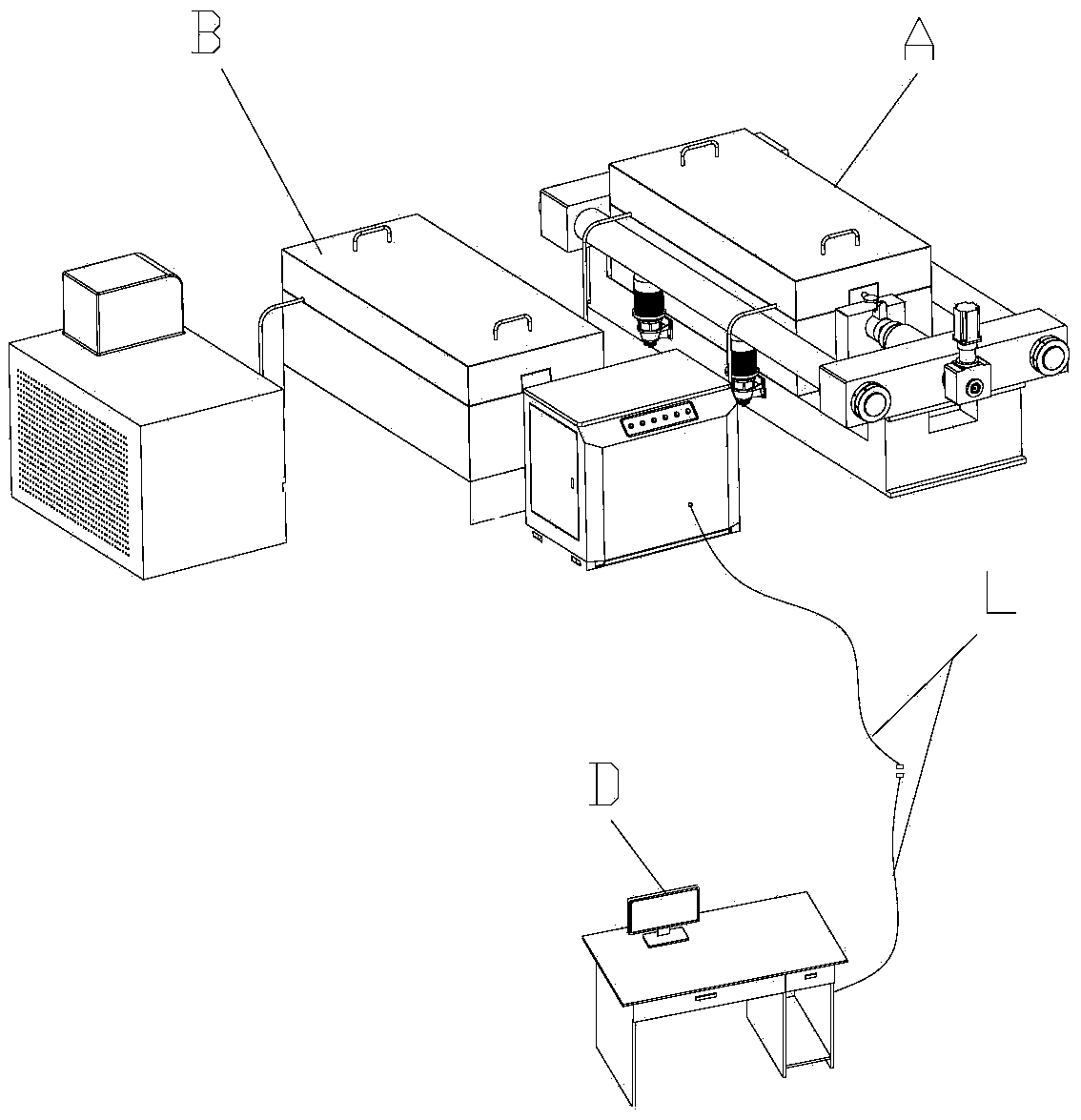

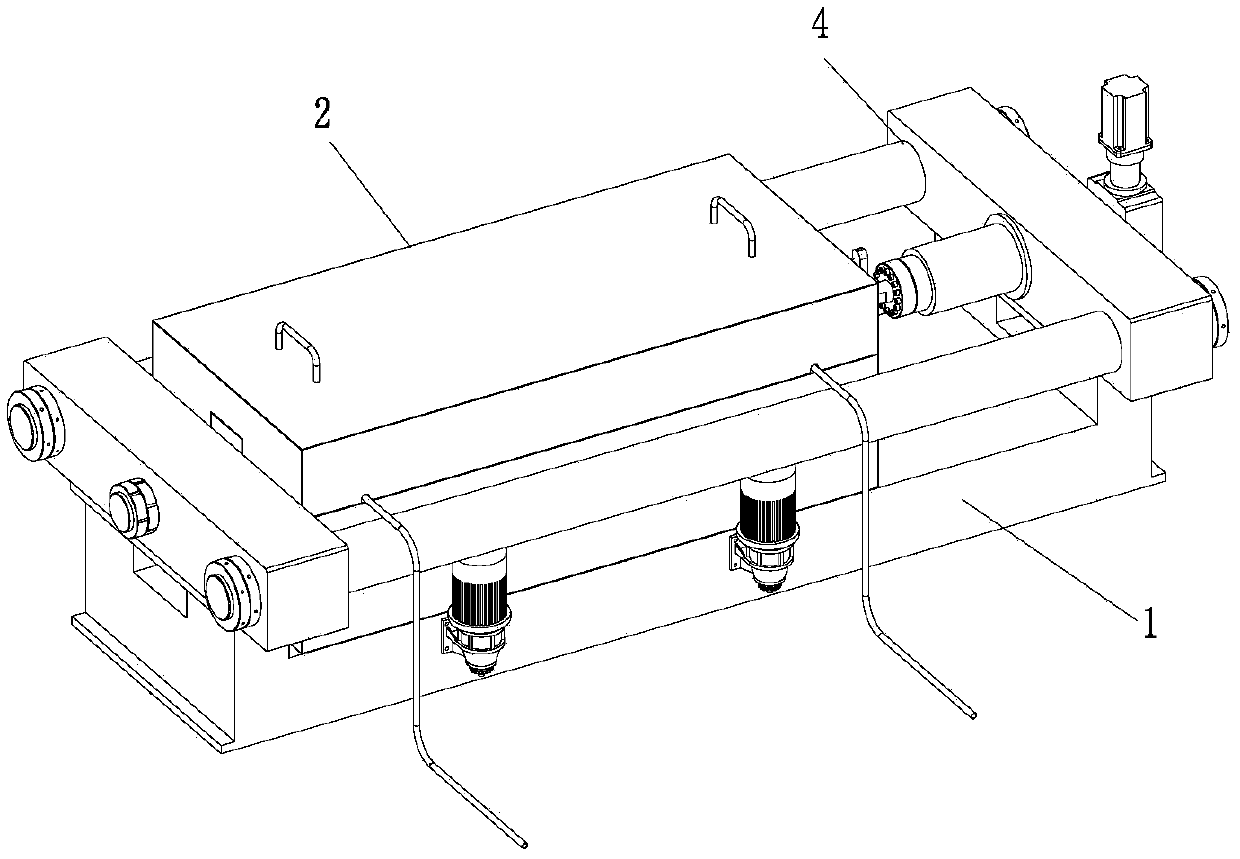

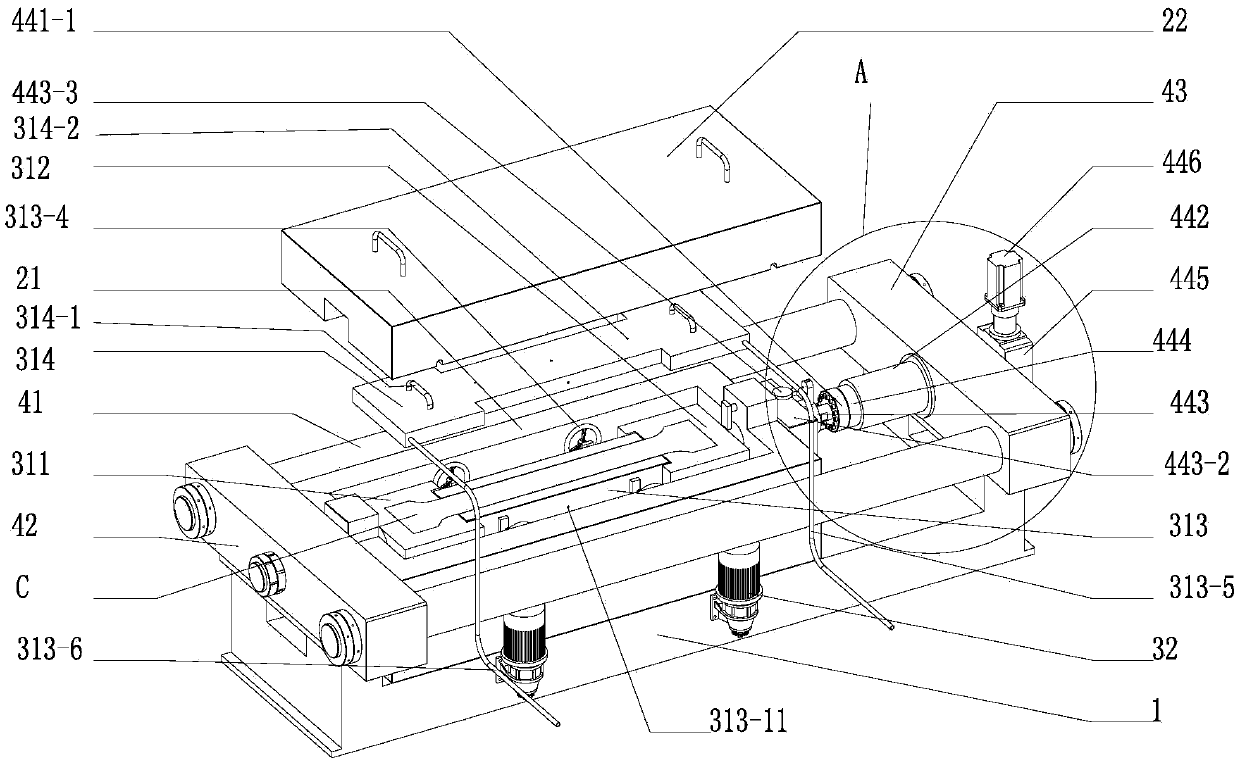

[0143] The whole process test device of concrete cracking based on the real environment provided by the present invention is as follows: figure 1 As shown, it includes a main testing machine A and an auxiliary testing machine B. Also be provided with computer D, computer D is connected with a control system D1 through data line L, and this control system D1 comprises:

[0144] 1. The control unit for controlling various actuators of the real environment simulation system in the main testing machine A and auxiliary testing machine B;

[0145] 2. The control unit of the actuator in the main testing machine A that controls the loading of the concrete specimen is the control unit of the power device in the loading system.

[0146] Data line L of computer D also connects:

[0147] 1. The signal output terminals of the temperature sensors monitoring the environmental parameters in the main testing machine A and auxiliary testing machine B;

[0148] 2. The signal output terminals of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com