Reactor melt retention apparatus

A technology in a melt and a device, which is applied in the field of the reactor melt retention device, and can solve the problems of threatening the integrity of the containment and the large-scale release of fission products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with specific embodiments. Wherein, the same reference numerals are used to denote the same or similar components. These examples are illustrative only, and the present invention is by no means intended to be limited to these illustrative examples only.

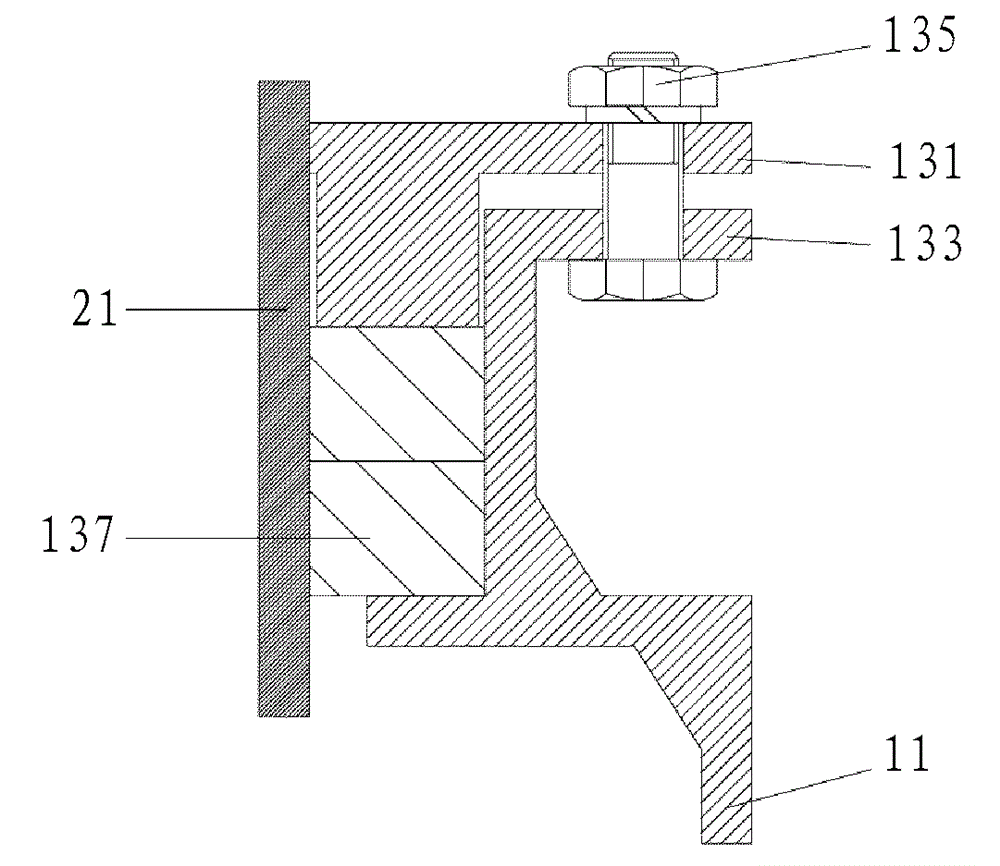

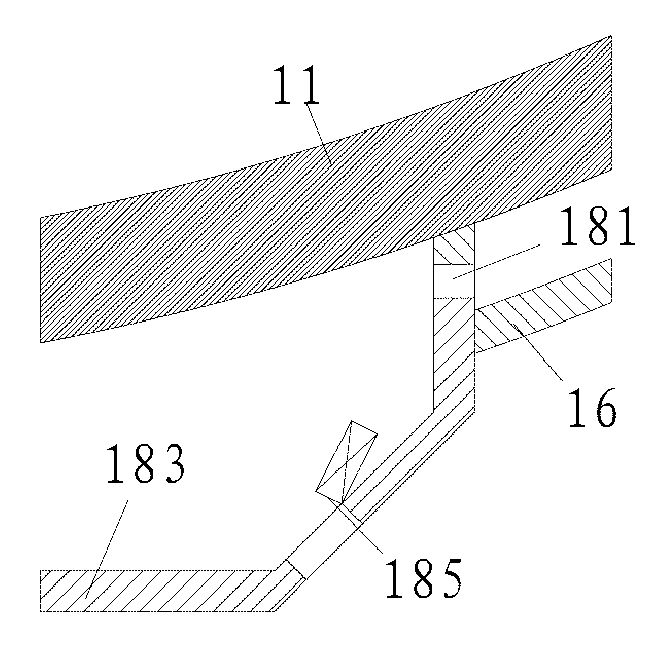

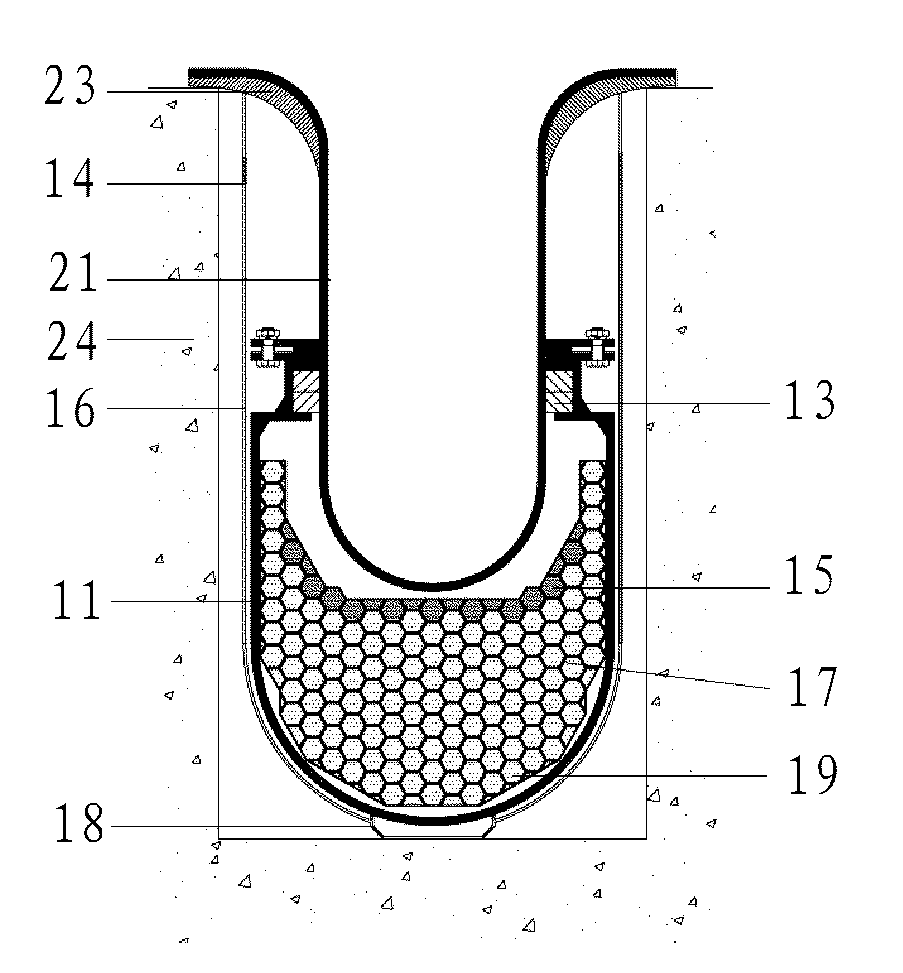

[0022] figure 1 A front cross-sectional view of a smelt retention device according to an embodiment of the invention is shown. The smelt retention device includes a trap housing 11 , a trap seal 13 , a sacrificial material 19 , a water inlet device 18 , and an insulation layer 16 . Sacrificial material 19 is disposed within trap housing 11 . The smelt retention device is entirely disposed in the space surrounded by the shielding wall 24 . The trap seal 13 is sealingly connected to the outer wall of the pressure vessel 21 . The insulation layer 16 is connected to the pressure vessel support 23 .

[0023] like figure 1 As mentioned above, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com