Method of processing oats to achieve oats with an increased avenanthramide content

A technology of oat alkaloids and oat flour, applied in the direction of food science, etc., can solve the problem of low ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

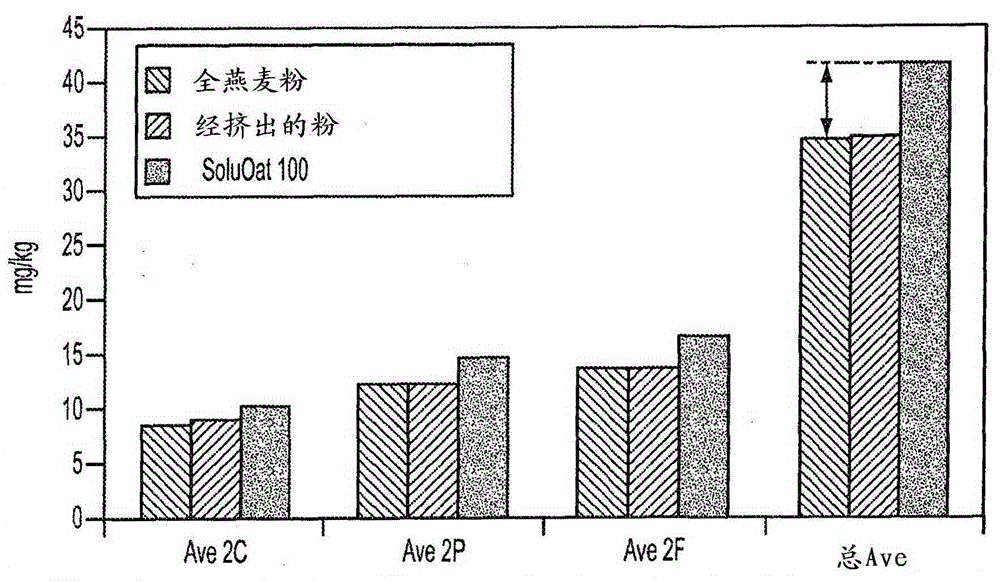

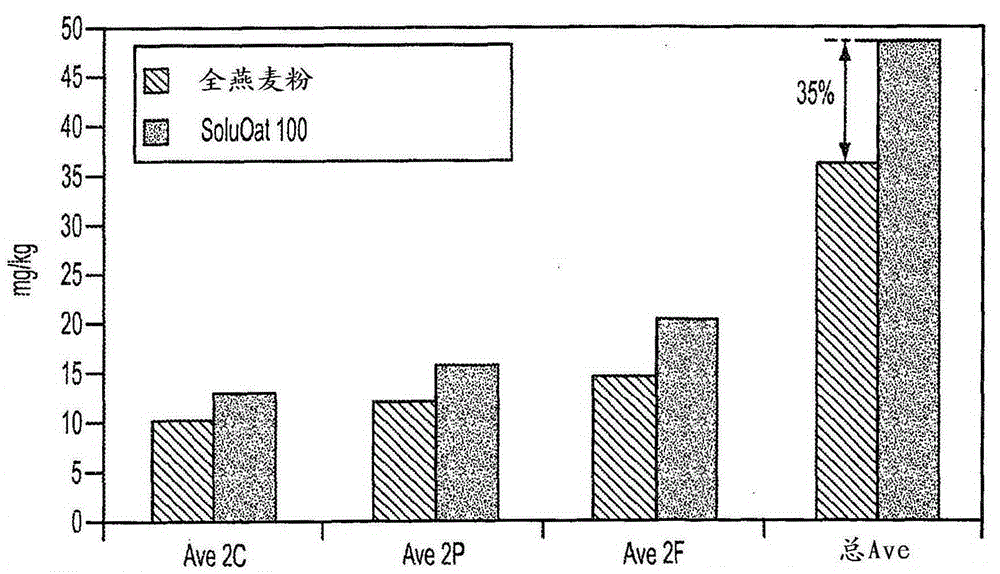

[0070] The avenal alkaloid levels of the resulting soluble oat flour were measured using reverse phase HPLC. Briefly, dehulled grains were extracted, dried and resuspended into aliquots. Aliquots were analyzed by HPLC with a C-18 column using a diode array spectrophotometer detector with detection at 340 nm. Peaks were quantified by comparison to a standard curve of authentic avena avenum alkaloids. The results of this test are illustrated in Figure 1A and Figure 1B middle. It was also found that the soluble oat flour prepared according to the methods described herein had a higher avenantrine content than oat flour processed by extrusion (without enzymes) alone.

[0071] specifically, Figure 1A Depicts avena alkaloids 2c, avena alkaloids 2p, avena alkaloids 2f and total avenum alkaloids (2c+2p+2f )level. As used herein, "SoluOat 100" or "SoluOat 100 flour" (whether singular or plural) shall refer to 99.5% whole oat flour and 0.5% mixed tocopherols made according to the p...

Embodiment 2

[0088] SoluOat Flour and Whole Oat Flour are manufactured in a conventional roller mill to produce an average particle size of 150 microns. Apply SoluOat powder to various types of food and beverages. The applications include instant powder applications, dry ingredients in baking and yogurt processing, and ready-to-drink (RTD) beverage applications. A grainy texture was observed in some finished applications containing SoluOat. The particle size of the SoluOat powder is believed to be primarily responsible for the grainy texture observed. "SoluOat", "SoluOat flour", "SoluOat90" or "regular SoluOat" (whether singular or plural) as used herein shall mean 90% whole oat flour, 5% sugar, 4.5 % maltodextrin and 0.5% mixed tocopherols.

[0089] The ground SoluOat powder was micronized using a FluidEnergy Micro-Jet Series 8 mill (jet mill) fitted with a bag at the discharge to collect the ground (micronized) powder. A Brabender volumetric screw feeder with a 1" diameter helical sc...

Embodiment 3

[0112] Samples for RVA / viscosity testing were prepared by milling the samples to pass through a 60 mesh screen. A 3.44 gram sample was measured on a dry weight basis and transferred to a sample pan. Deionized water was added to the sample to bring the total weight to 29 grams.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com