Bearing variable preload system utilizing gap between strokes for preload adjustment and elastic deformation of sealing member

A sealing material and elastic deformation technology, applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve the problems of supporting mandrel bearings becoming smaller, bearing life shortening, and preloading, etc., so as to improve illuminance, prolong life, The effect of improving the efficiency of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

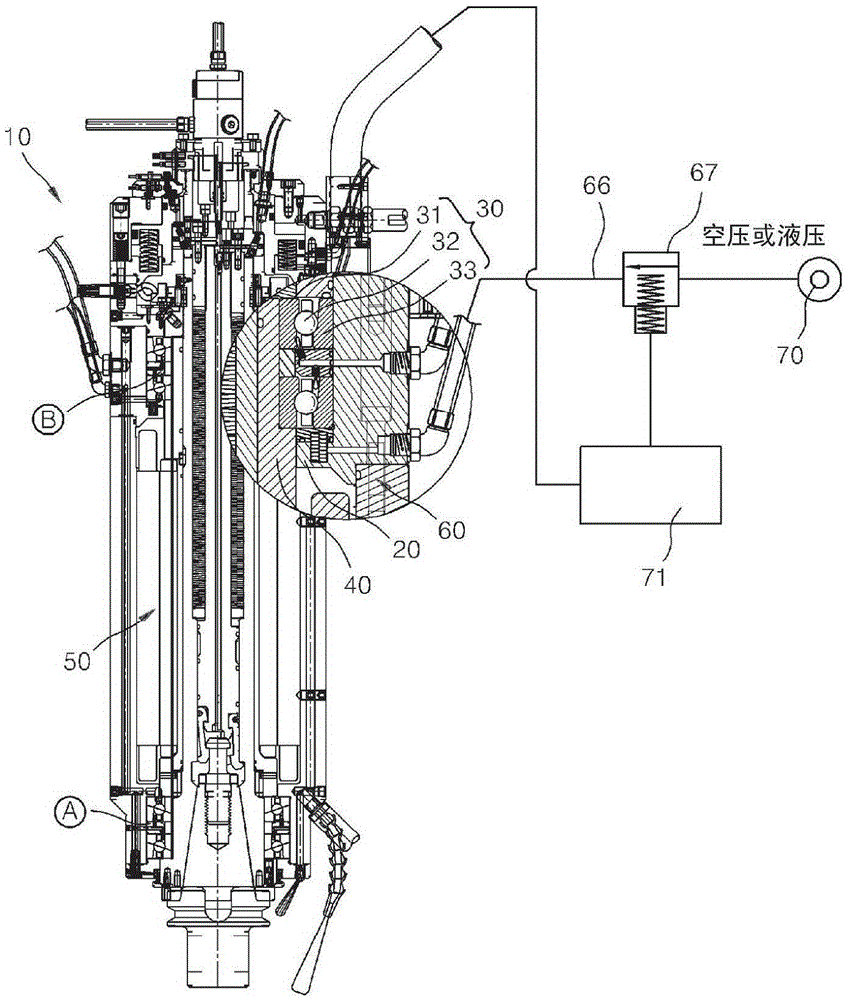

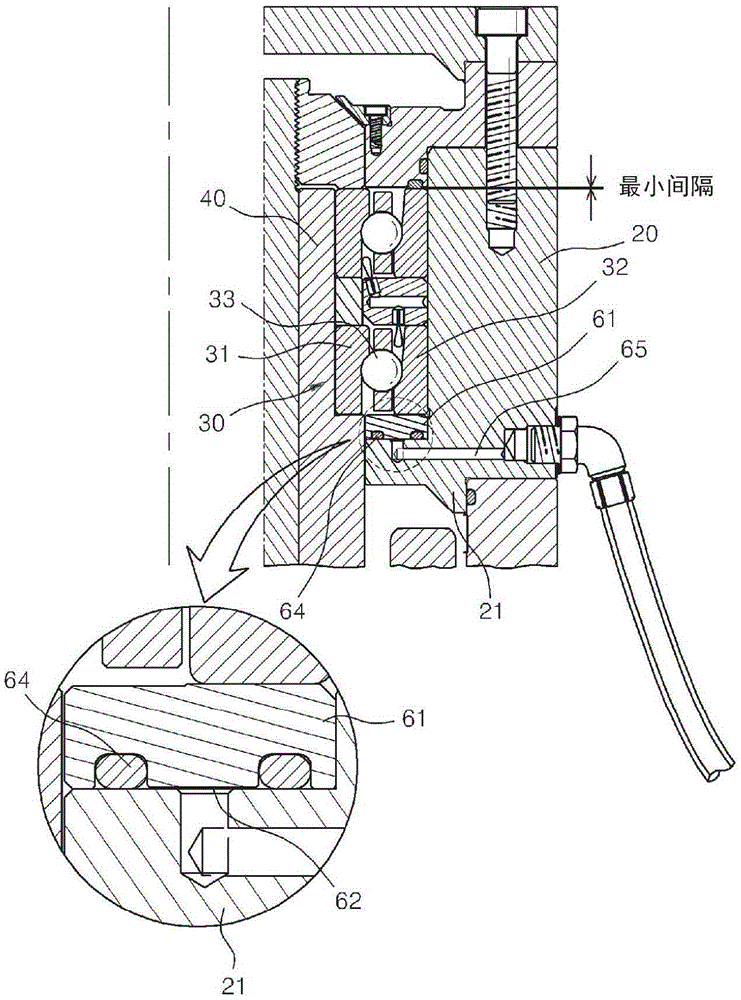

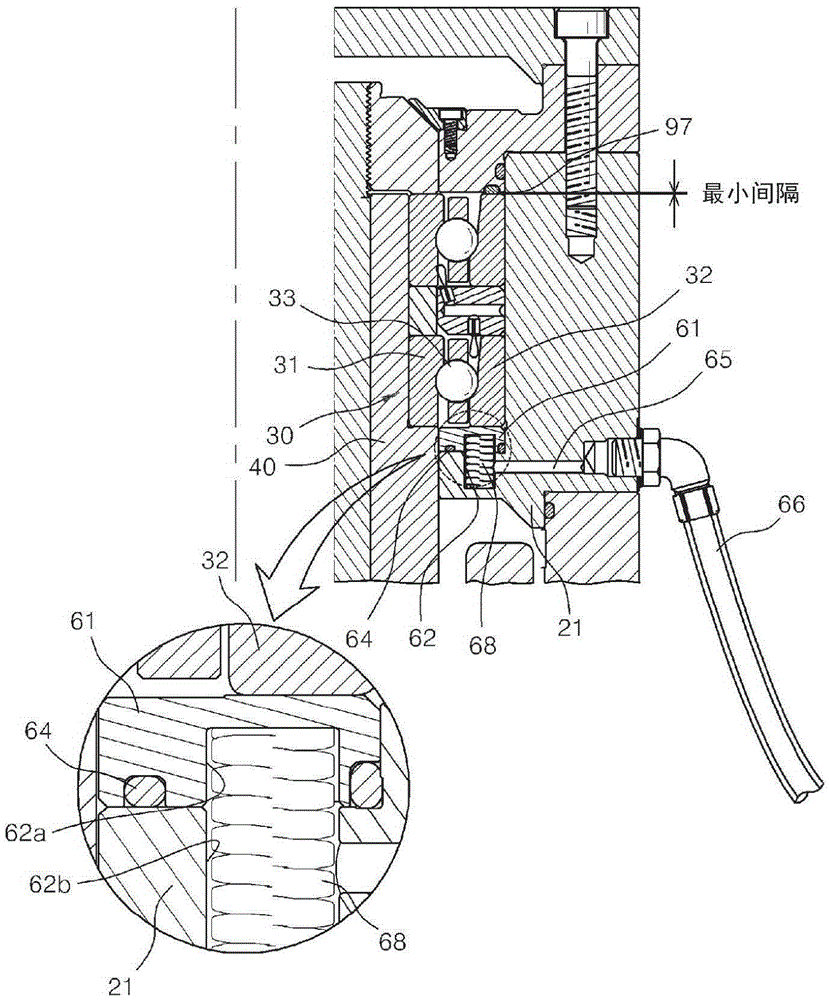

[0038] According to the variable preload system of bearings utilizing stroke gap and elastic deformation of sealing material for adjusting preload according to the present invention, it is used to apply constant pressure and variable preload to bearings supporting spindle system spindles of machine tools, as follows by Figure 1 to Figure 7 Be explained.

[0039] As shown in the figure, a variable preload system 10 for a bearing that utilizes the stroke clearance and elastic deformation of the sealing material in order to adjust the preload according to the present invention is used for a bearing that is installed in the spindle housing of a machine tool and supports the spindle. The outer ring is preloaded and includes an inner ring 31, an outer ring 32, and a bearing 30 with a ball 33 disposed between the outer ring and the inner ring. The inner ring of the bearing 30 located in the housing 20 is provided with a spindle 40 for rotation.

[0040] Spacers are arranged between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com