Rubber composition and pneumatic tire using same

A rubber composition, natural rubber technology, applied in special tires, tire parts, transportation and packaging, etc., can solve problems such as poor appearance of tire sidewalls, and achieve the effect of preventing poor appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

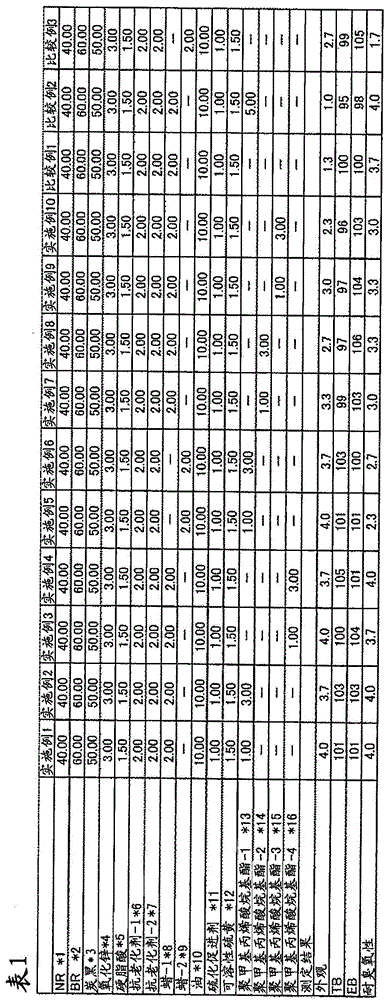

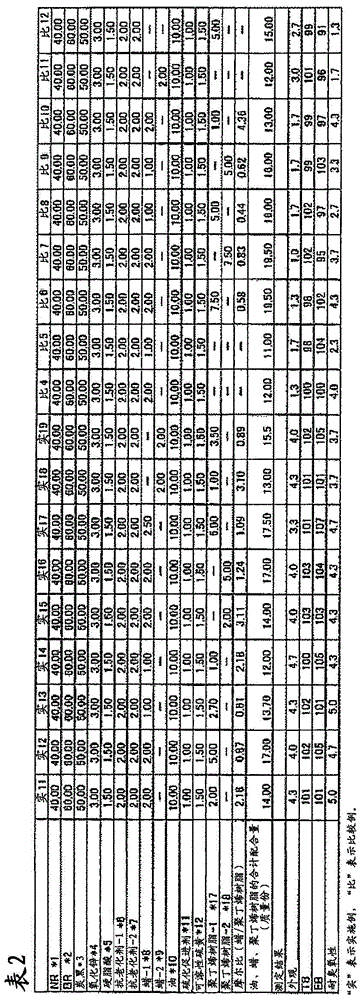

Embodiment 1~19 and comparative example 1~12

[0069] sample preparation

[0070] Mix the ingredients (parts by mass) shown in Table 1 and Table 2 except the vulcanization accelerator and sulfur in a 1.7-liter closed Banbury mixer for 5 minutes, and then place it at about 150°C for mixing. Outside the machine, cool at room temperature. Next, a vulcanization accelerator and sulfur were added to this composition, and the mixture was kneaded with open rolls to obtain a rubber composition. Next, the obtained rubber composition was vulcanized by pressing in a predetermined mold at 170° C. for 10 minutes to obtain vulcanized rubber test pieces, and the physical properties of the vulcanized rubber test pieces were measured by the following test methods.

[0071] Appearance: It left still in the oven of 40 degreeC for 2 weeks, and visually evaluated according to the following standard.

[0072] Point 1: Whitened as a whole.

[0073] Point 2: About 30% of the whole area turns white.

[0074] Point 3: The overall hair is black. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com