Patents

Literature

46results about How to "Achieve secondary cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

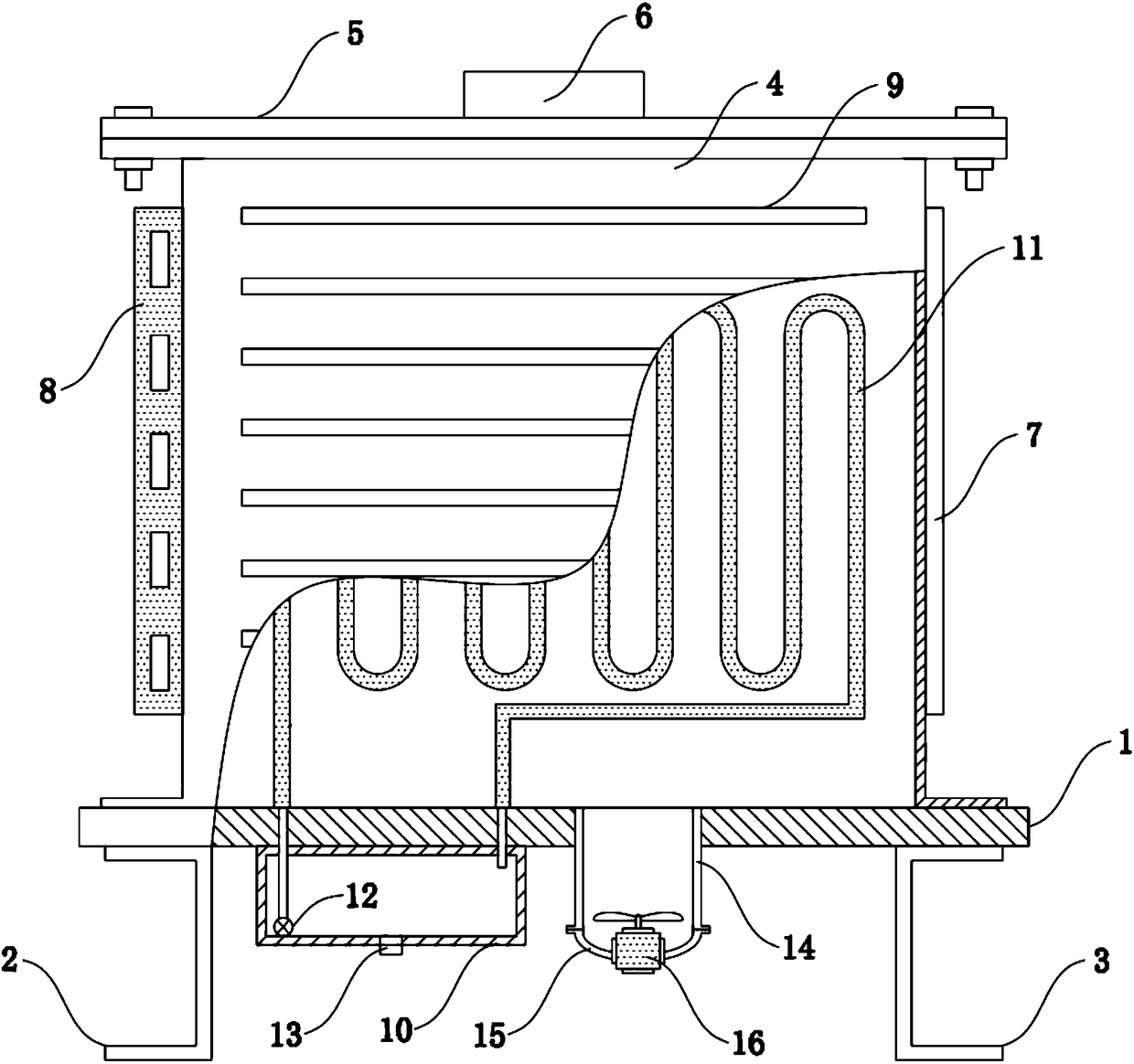

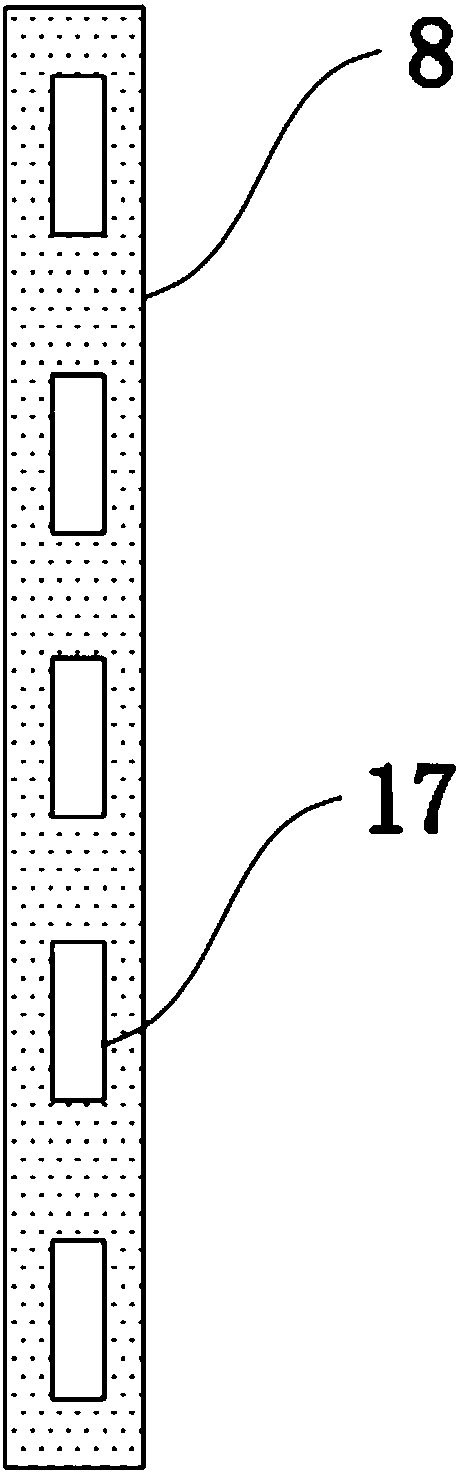

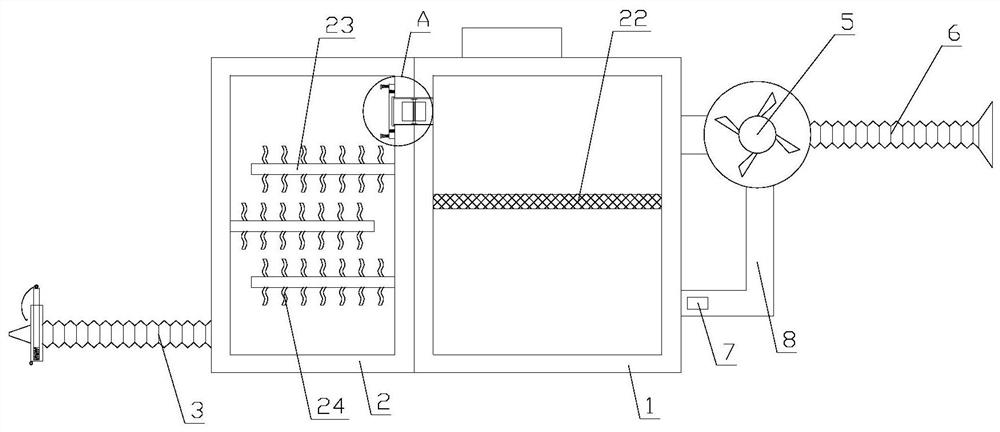

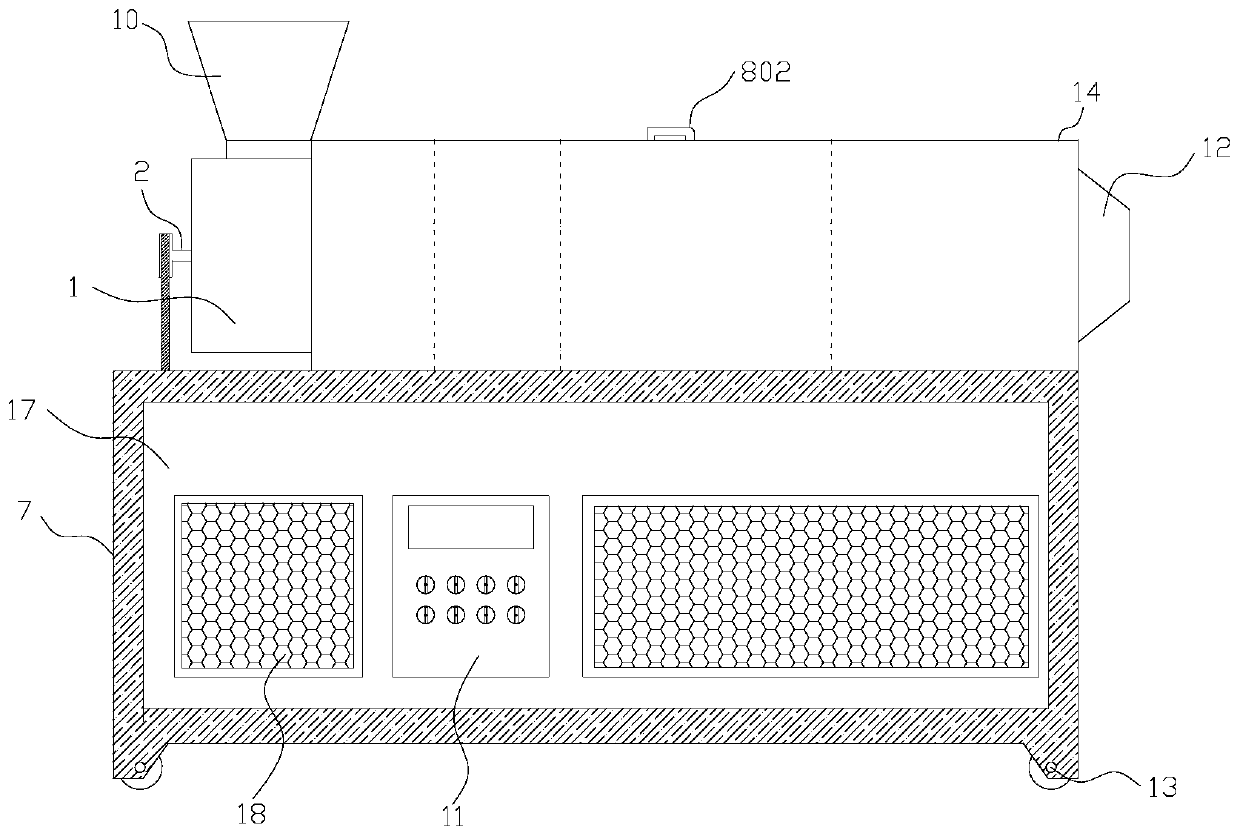

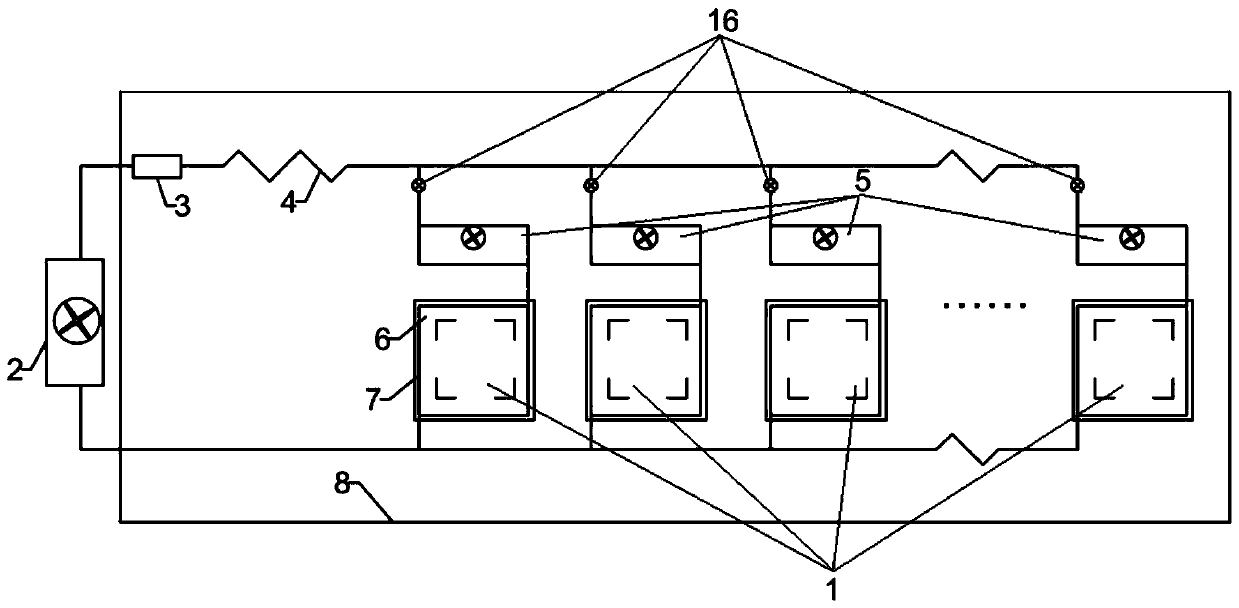

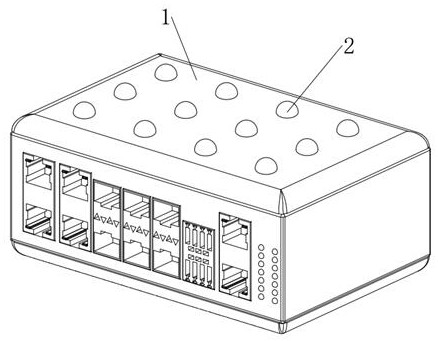

Power distribution cabinet cooling system and method

InactiveCN108565728AIncrease cooling areaAchieve primary coolingSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineeringHeat sink

The invention discloses a power distribution cabinet cooling system and method. The system has the advantages that the heat radiating area of a power distribution cabinet casing is increased through the arrangement of a first cooling fin and a second cooling fin, the heat dispersion performance is further enhanced through forming of heat emission hole in both the first cooling fin and the second cooling fin, primary cooling of the power distribution cabinet casing is realized, water in a water tank is pumped into S-shaped heat exchange tubes through a circulating water cooling principle, uniform distribution of the S-shaped heat exchange tubes in the power distribution cabinet casing can continuously absorb heat in the power distribution cabinet casing into cooling liquid in the S-shaped heat exchange tubes, secondary cooling of the power distribution cabinet casing is realized, an end part of an exhaust pipe is fixedly equipped with a fan body through a bracket through an air coolingprinciple, external air enters the interior of the power distribution cabinet casing from an air inlet pipe, and high-temperature air in the power distribution cabinet casing is discharged through theexhaust pipe, so that tertiary cooling of the power distribution cabinet casing is realized, and various cooling modes coexist.

Owner:滁州瑞能电力科技有限公司

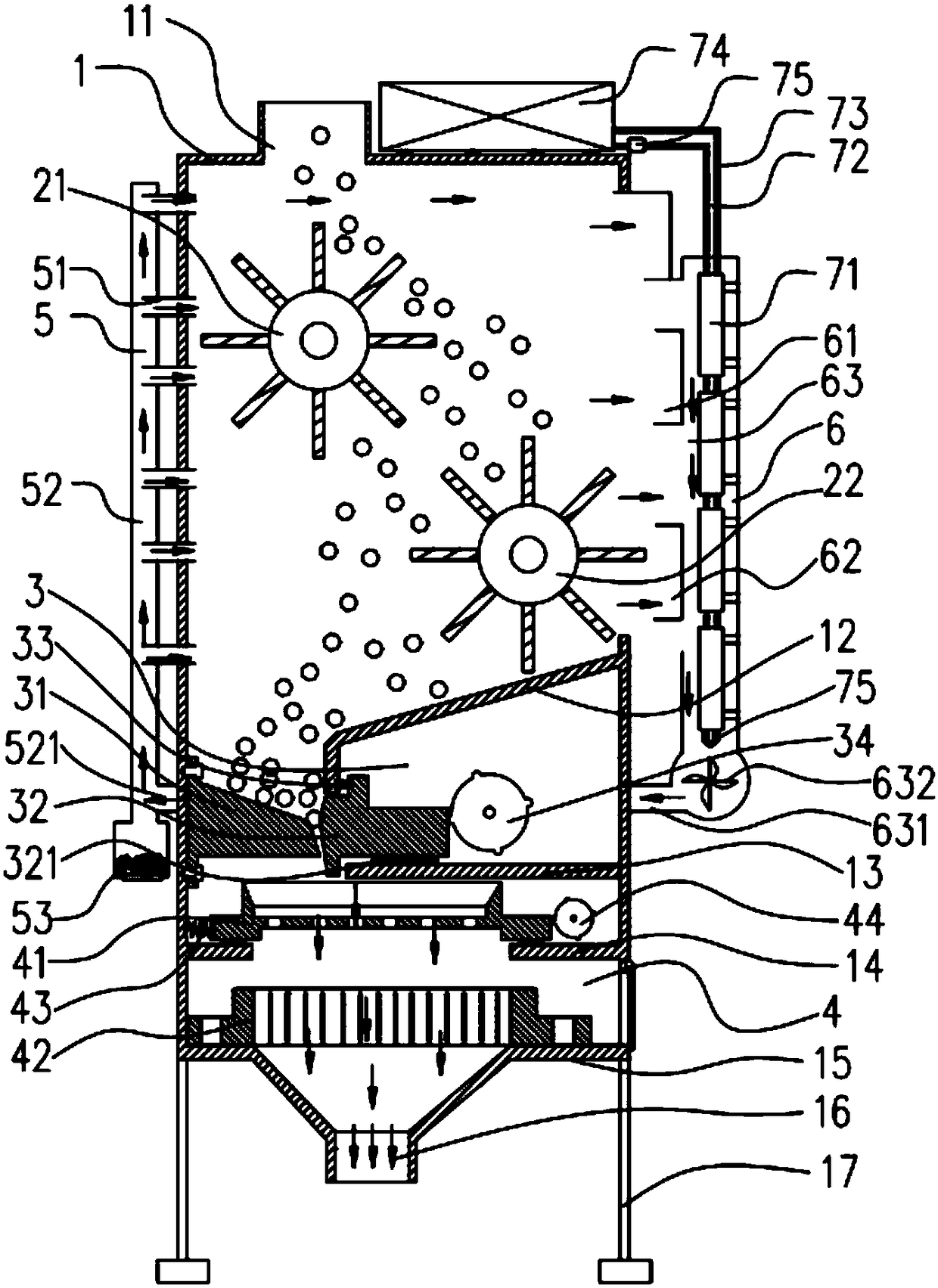

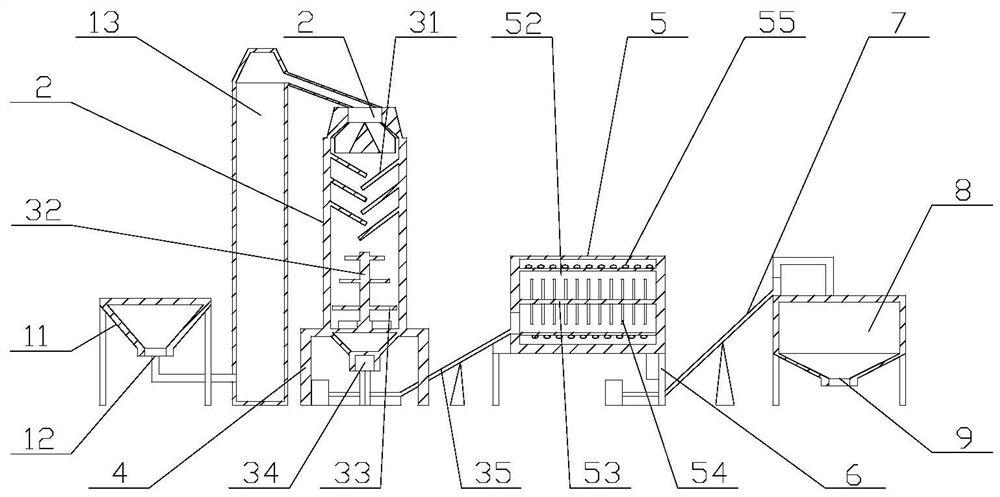

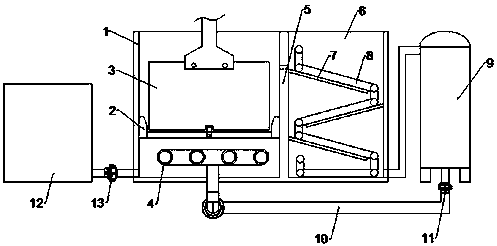

Environmental-protection molding sand cooling recovery device

InactiveCN108436030AGuaranteed homogeneityReduce the temperatureMould handling/dressing devicesCooling effectEngineering

The invention discloses an environmental-protection molding sand cooling recovery device. The device comprises a tower body, and a first separation plate, a second separation plate and a blanking collecting plate arranged in the tower body in sequence from top to bottom; a crushing bin is fixedly connected with a fixed inclined surface end, a slide inclined surface end and a first driving cam in sequence from left to right; a first return spring is arranged between the slide inclined surface end and the first separation plate; the first driving cam is matched with the right side surface of theslide inclined surface end, and can butt against the slide inclined surface end to move to the left side to realize pressing of the first return spring; when the first return spring is reset, the slide inclined surface end can be driven to move to the right side; a discharge port is formed in the lower part of the blanking collecting plate; and the tower body is provided with a cooling intake endon the left side wall and an air collecting device on the right side wall. The device cools molding sand through the cooling intake end and the air collecting device, achieves better cooling effect,and is compact in structure, convenient to use, energy-saving, environment-friendly and suitable for wide application in cooling recovery of the molding sand.

Owner:李同贵

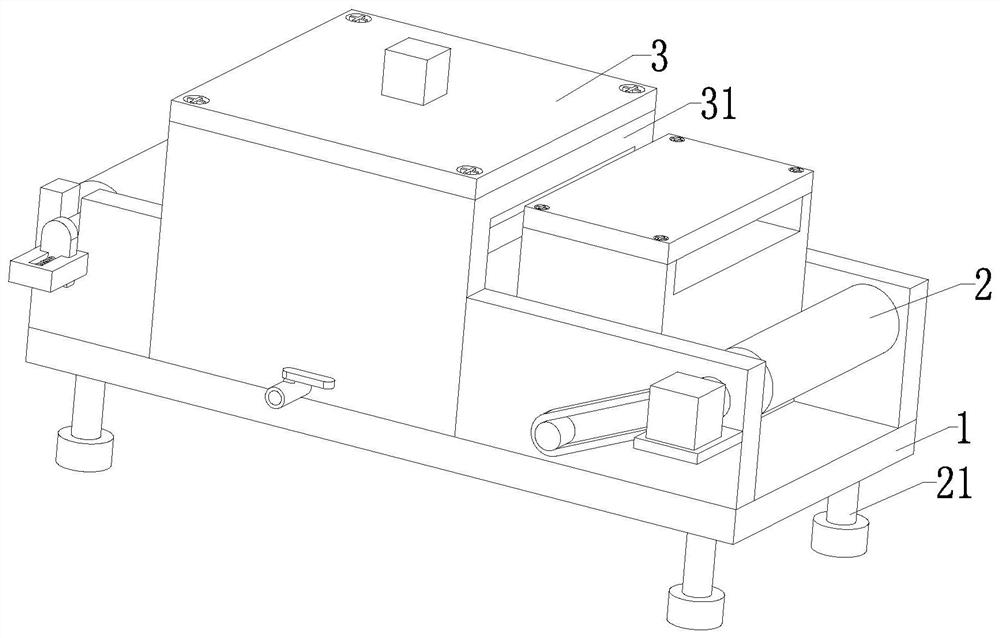

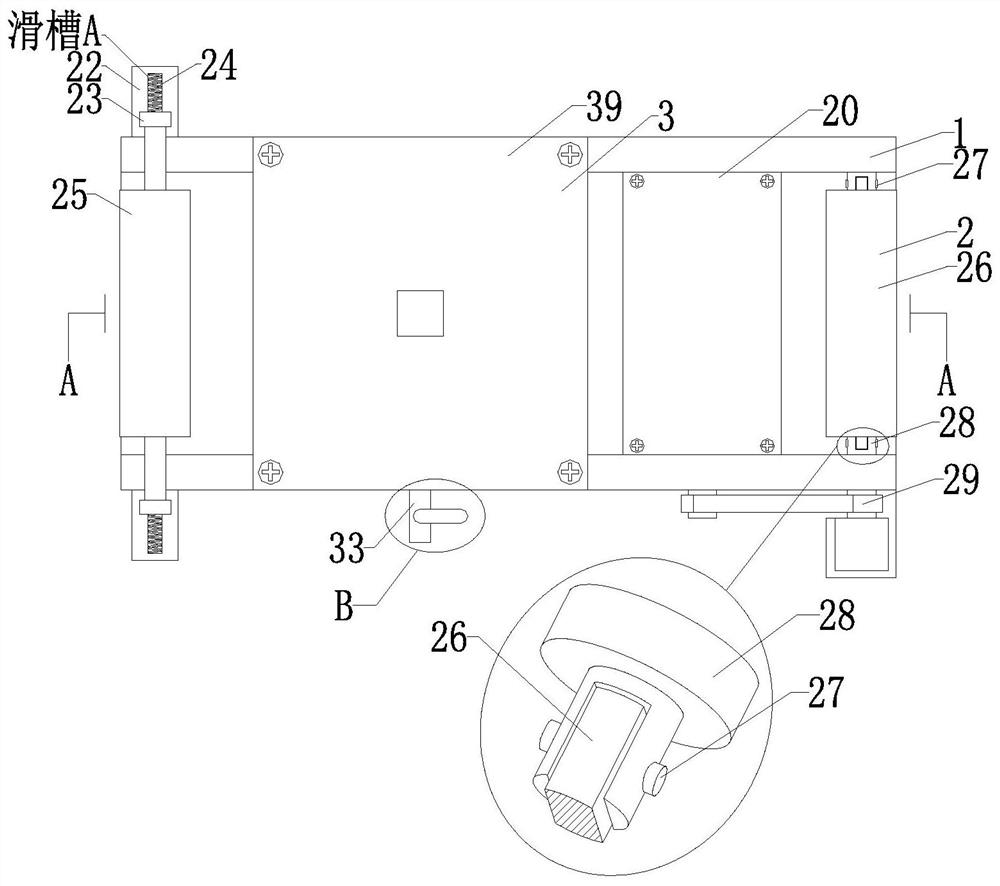

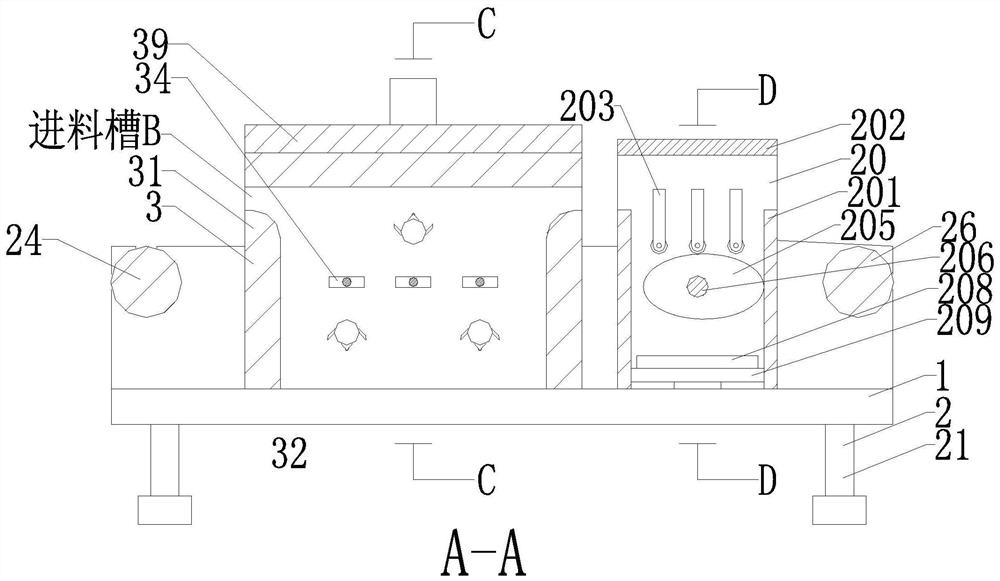

Zinc alloy forming and cooling integrated production device

ActiveCN112222397AStable cooling molding effectGuaranteed stable transmissionCasting plantsPhysicsChain type

The invention relates to a zinc alloy forming and cooling integrated production device in the field of alloy forming devices, comprising a cooling system. The cooling system comprises a water tank; aplurality of clamping assemblies used for movably clamping the edges of the two sides of a chain type conveying belt are arranged at the middle of the inner side of the water tank; a mounting plate isarranged above the water tank; the clamping assemblies are mounted on the mounting plate; the cooling system further comprises a driving part used for driving the mounting plate to ascend and descend; a speed sensor is arranged on a driving wheel of the chain type conveying belt; the speed sensor is electrically connected with a console; a plurality of driving parts are all electrically connectedwith the console; when the speed sensor detects that the rotating speed of the driving wheel of the chain type conveying belt is higher than a set value, the console controls different numbers of driving parts to be started and drives the mounting plate to move downwards; and the higher the rotating speed of the driving wheel of the chain type conveying belt is, the larger the controlled startingnumber of the driving parts is. The device has the effects that the zinc alloy production rate can be automatically monitored, and the cooling forming quality is correspondingly improved.

Owner:佛山市桂源锌合金材料有限公司

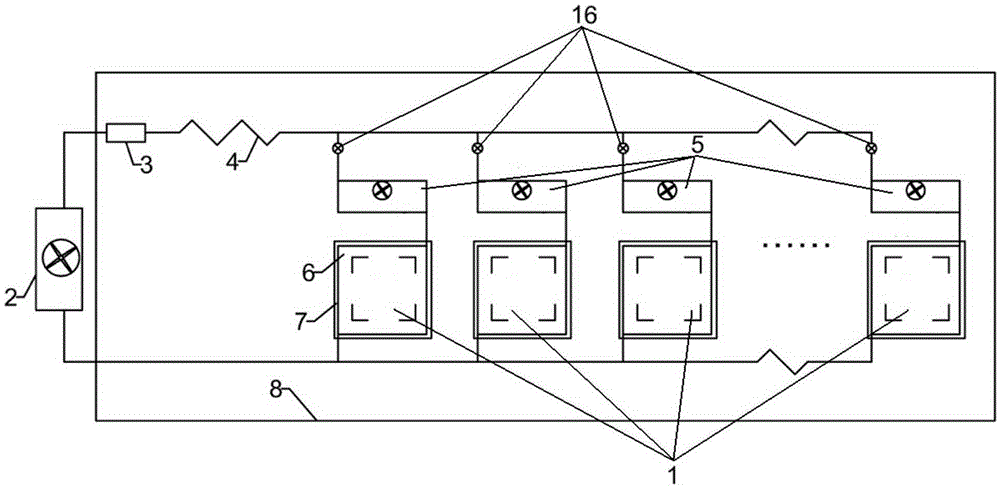

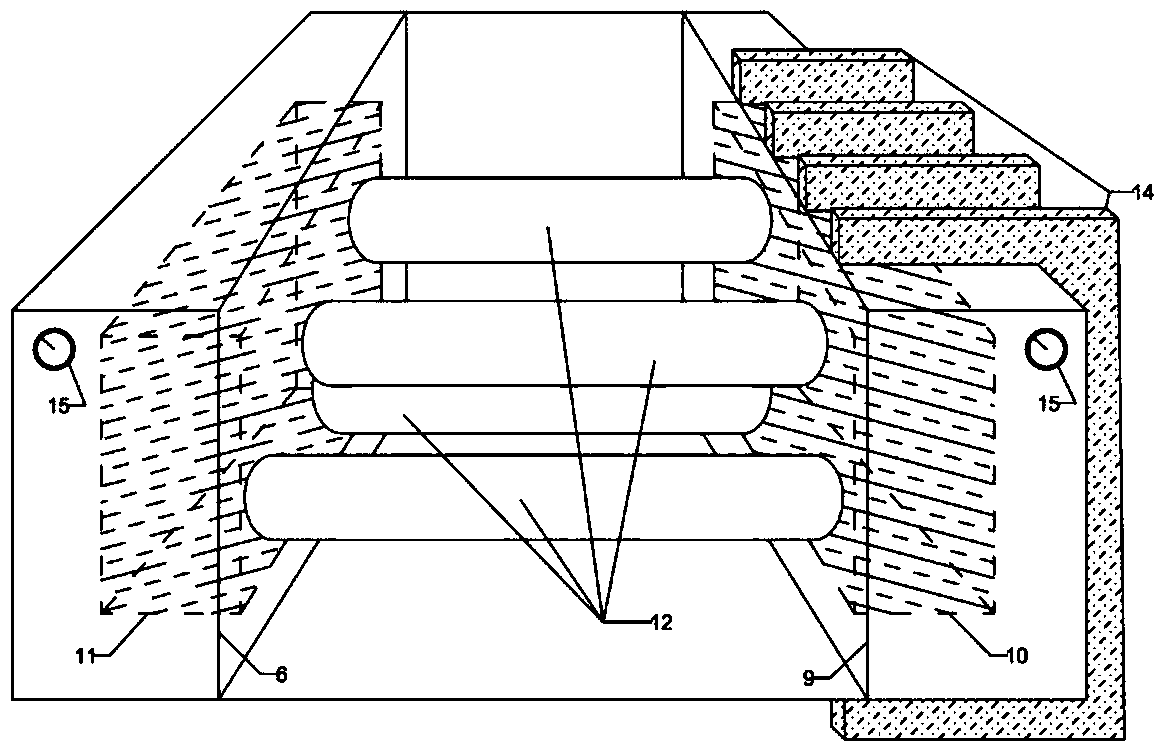

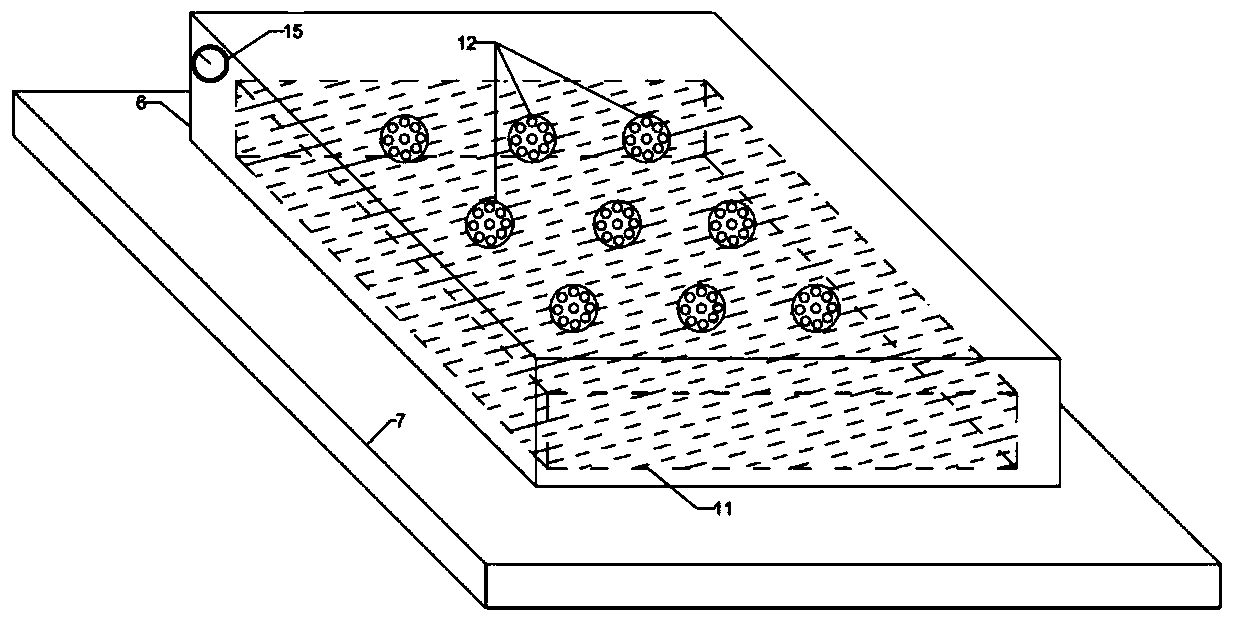

Knudsen effect-based electronic component cooling device and method

ActiveCN105431017AImprove cooling efficiencyImprove cooling effectModifications using liquid coolingHeat sinkEvaporator

The invention discloses a Knudsen effect-based electronic component cooling device and method. The device comprises a plurality of heat sinks, a plurality of metal components respectively corresponding to the heat sinks one by one, a plurality of Knudsen compressors, a condenser, a capillary throttling pipe and a plurality of evaporators, wherein each Knudsen compressor comprises a cooling cavity, a hot cavity and a micro-channel, and each evaporator corresponds to a heating part of an electronic component. A Knudsen effect-based cooling system design is integrated on a cooling device for heating electronic components to replace the conventional heat dissipation and cooling device, and refrigeration can be realized by directly utilizing heat released by the electronic components to realize secondary cooling, so that the cooling efficiency and the cooling effect are improved, and the device and the method have a higher application value in the field of electronic component cooling.

Owner:GUANGXI UNIV

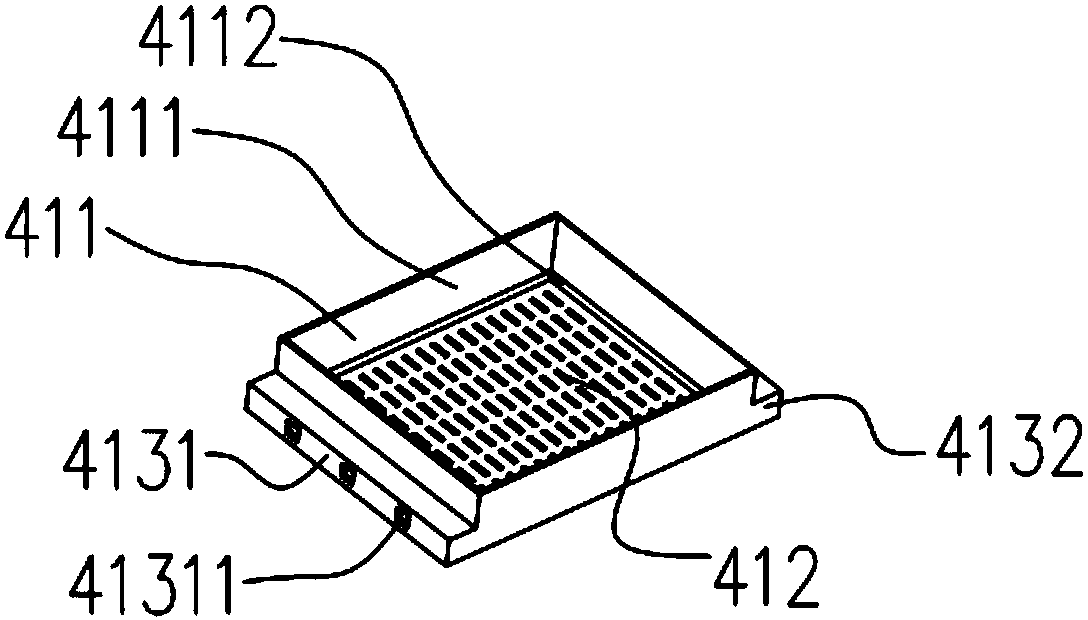

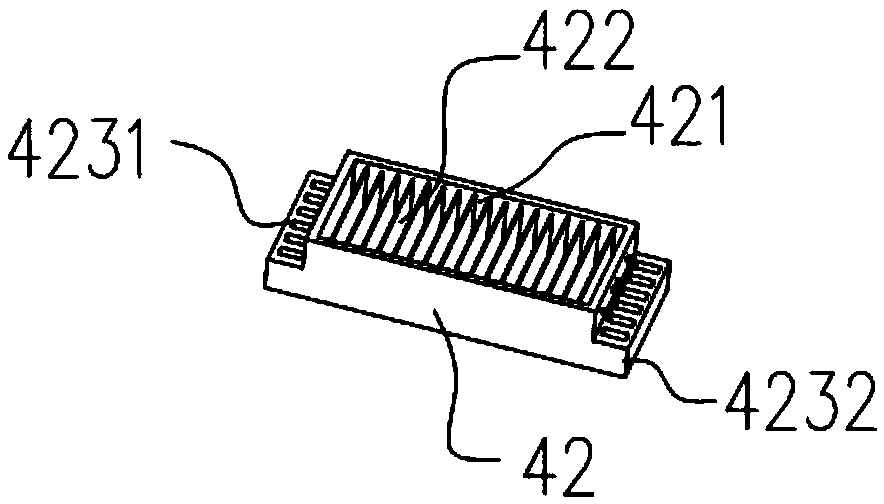

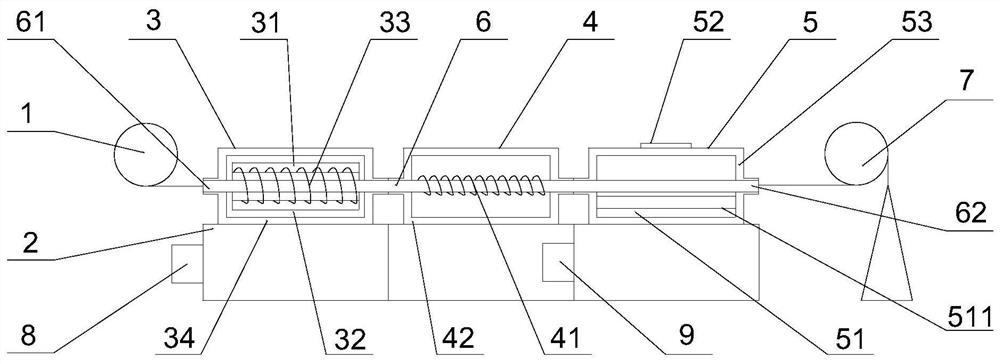

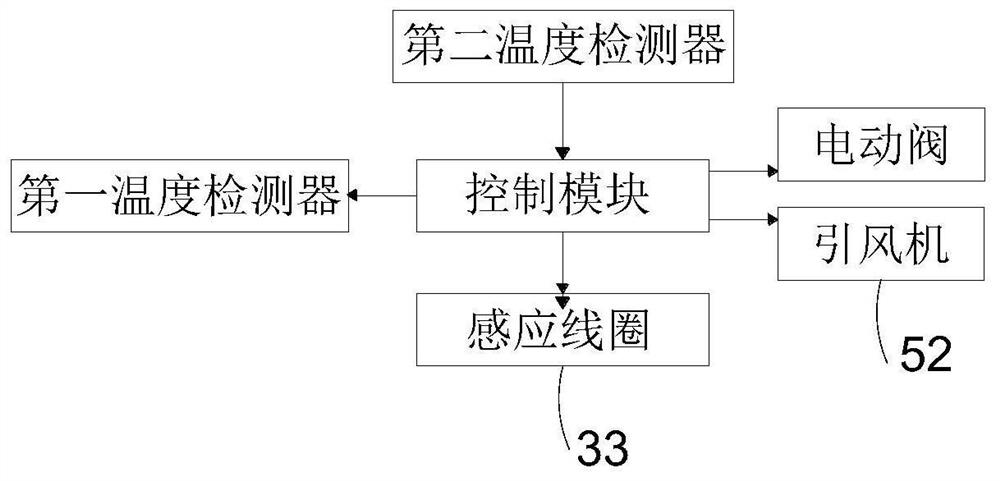

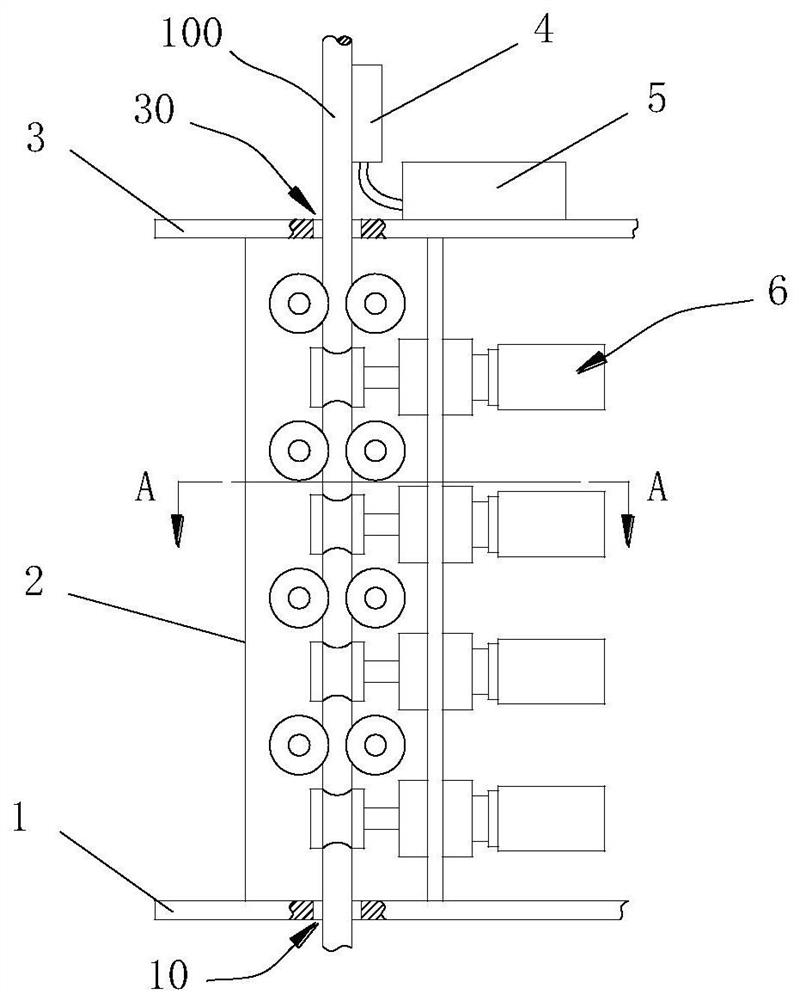

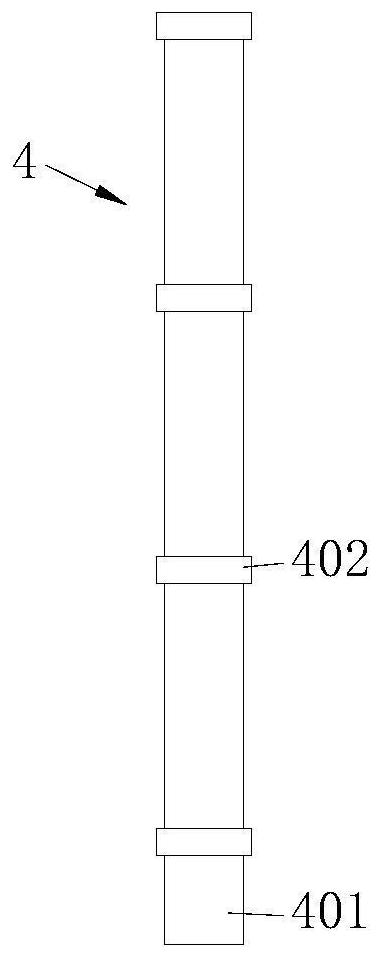

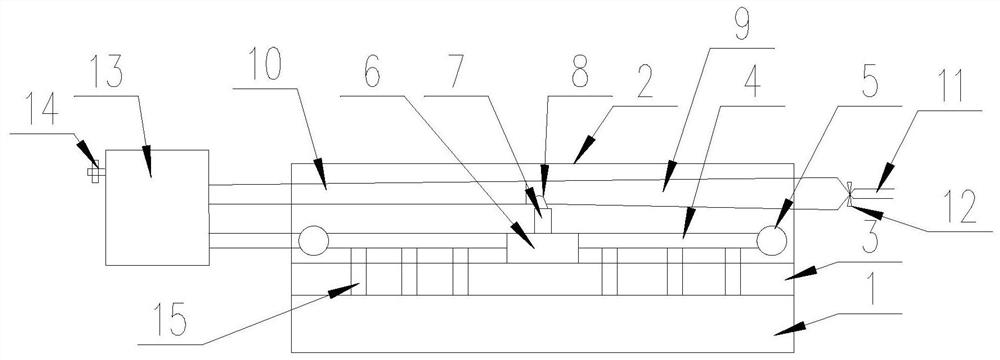

Fireproof cable conveying equipment with annealing function

PendingCN112538560AShort heating timeImprove heating efficiencyFurnace typesIncreasing energy efficiencyInformation controlInsulation layer

The invention relates to fireproof cable conveying equipment with an annealing function, and belongs to the field of fireproof cable preparation. The equipment is used for achieving the functions of conveying and annealing a fireproof cable. The equipment comprises a base support and a fireproof cable conveying passage arranged on the base support, wherein the fireproof cable conveying passage isprovided with an induction heating box, a first cooling box and a second cooling box sequentially in the conveying direction of the fireproof cable, the induction heating box further comprises a high-temperature cavity, a thermal insulation layer, an induction coil and a first protection layer and is used for heating the fireproof cable, the first cooling box and the second cooling box are matchedto realize cooling of the fireproof cable, and a control module controls the heating and cooling process of the fireproof cable according to detection information of a detection module. Therefore, the annealing efficiency of the fireproof cable is improved, and resource waste is effectively reduced.

Owner:GUANGDONG SHENGYU CABLES IND

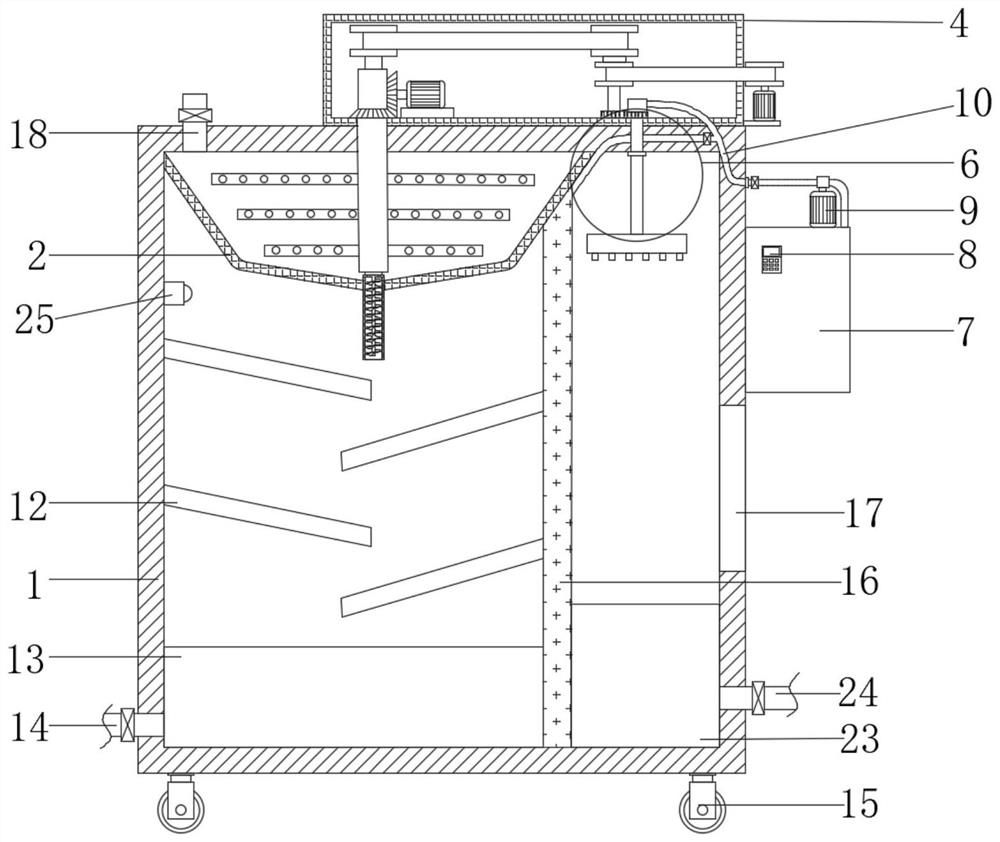

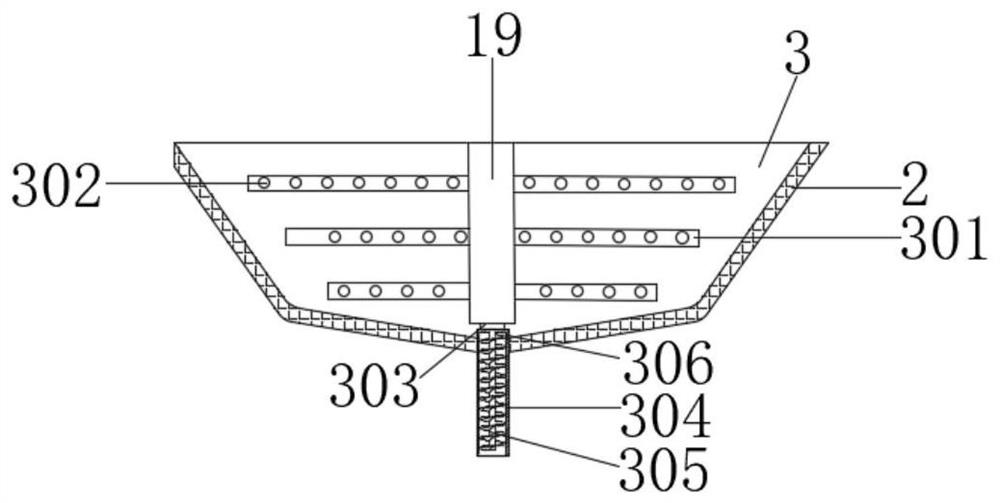

Cooling device for research on low-alloy smelting of vanadium and application method of cooling device

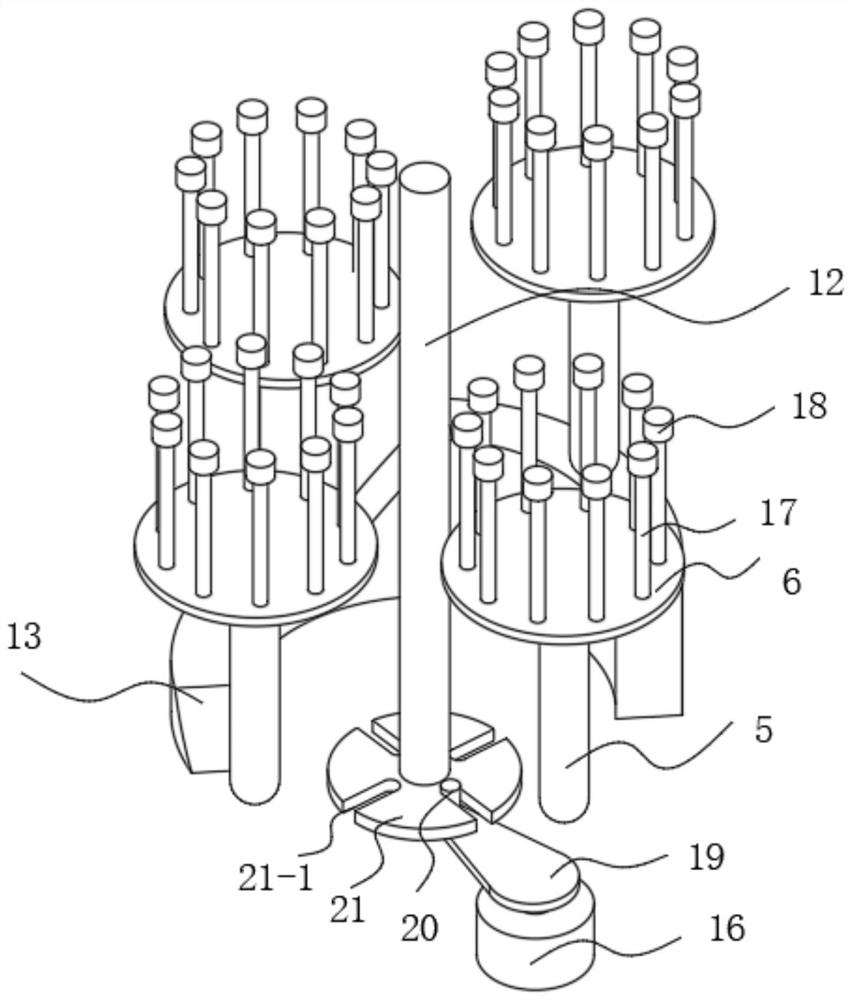

InactiveCN113324406AFalling speed controlAvoid blockageStirring devicesCharge manipulationElectric machineryProcess engineering

The invention discloses a cooling device for research on low-alloy smelting of vanadium and an application method of the cooling device, and relates to the technical field of vanadium smelting equipment. The cooling device comprises a smelting treatment box, wherein a stirring tank is fixedly connected to the interior of the smelting treatment box; a stirring quantitative component is installed in the stirring tank; the stirring quantitative component comprises an agitator arm and a through hole; and a sleeve is rotationally connected to the interior of the stirring tank. The device has the beneficial effects that the stirring quantitative component is arranged, the falling speed during vanadium smelting is controlled, and the blockage condition is avoided, the service life of the equipment is prolonged; a rotating component is arranged, the two components are driven to operate by only installing one motor, and the cost is greatly saved; a water curtain plate and a negative pressure fan are arranged, overall cooling treatment of the interior of the smelting treatment box is achieved; a spraying cooling component and a temperature sensor are arranged, the cooling treatment efficiency of the interior of the smelting treatment box is improved, and secondary cooling is achieved.

Owner:CHENGYU VANADIUM TITANIUM TECH CO LTD

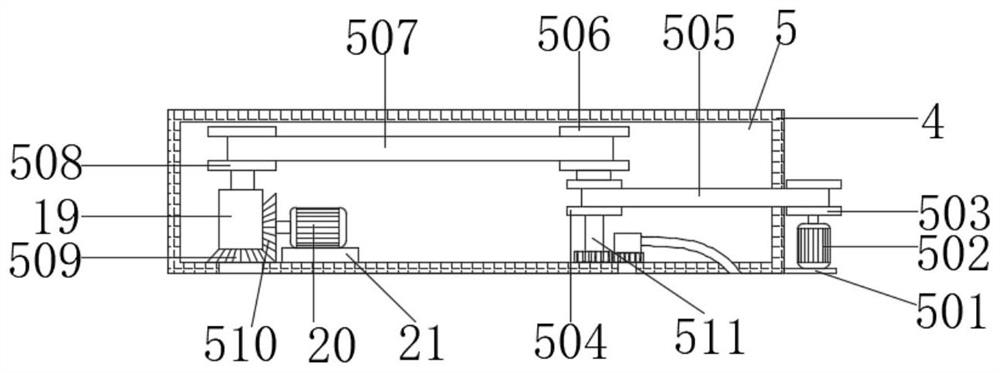

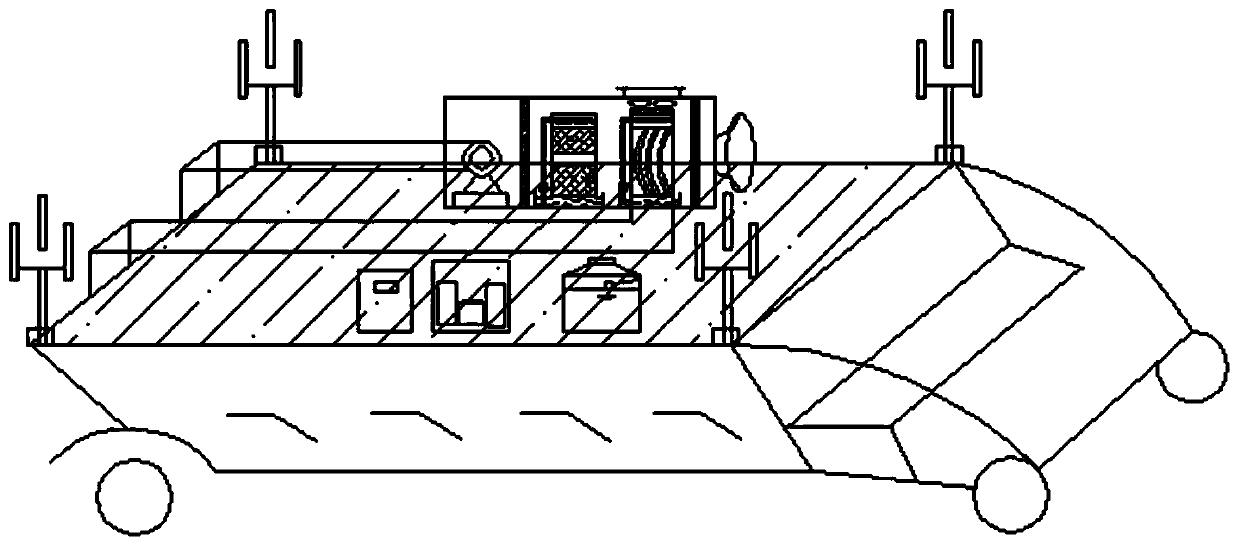

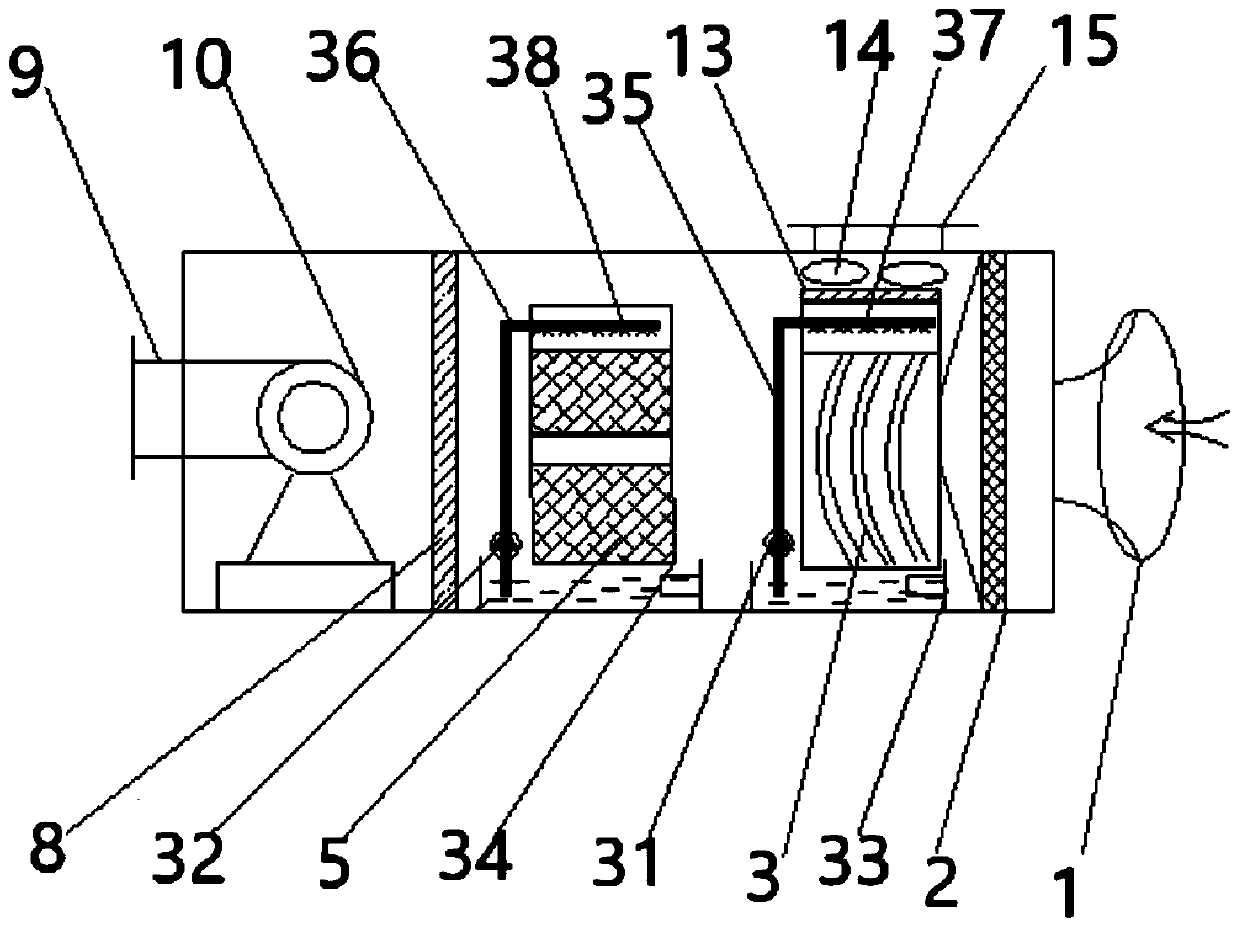

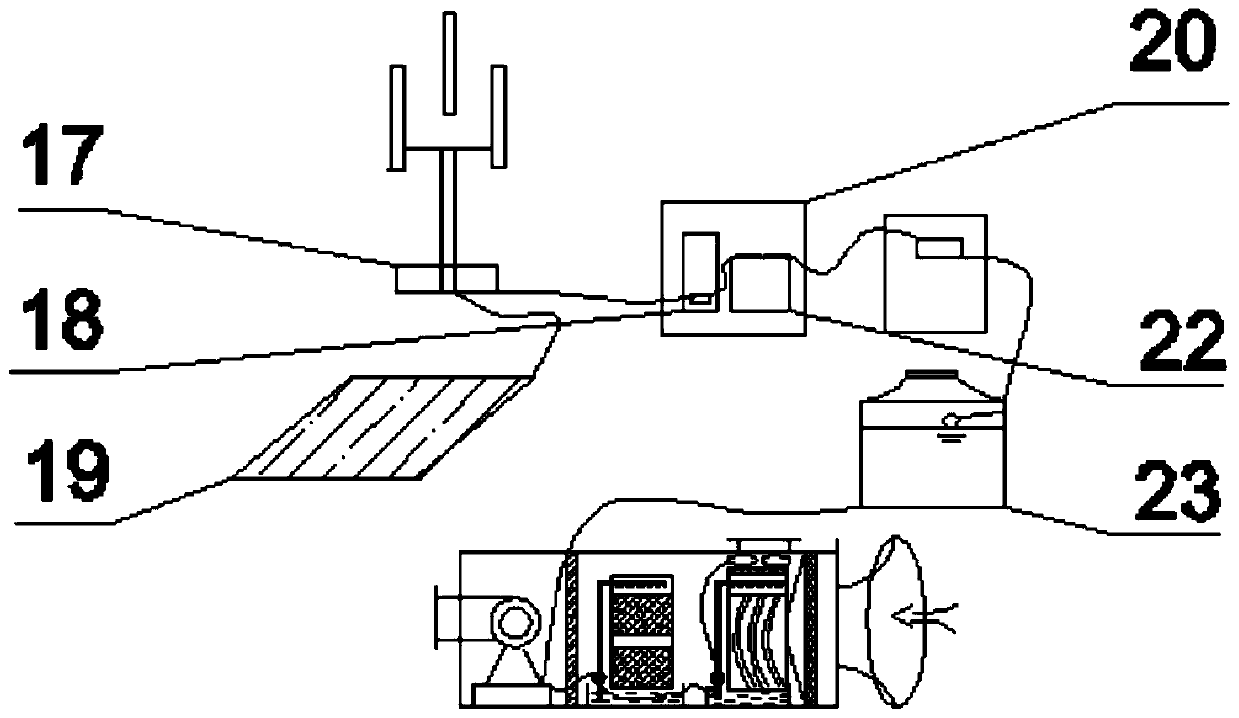

Sightseeing vehicle based on new energy composite air conditioning system

InactiveCN109968946AAchieve coolingAchieve cooling againAir-treating devicesBatteries circuit arrangementsEvaporative coolerControl system

The invention discloses a sightseeing vehicle based on a new energy composite air conditioning system. The key point of the technical scheme is that the sightseeing vehicle based on the new energy composite air conditioning system comprises a refrigerating unit; an air inlet and an air supply opening are formed in the refrigerating unit; the air inlet and the air supply opening correspondingly face towards the front and rear ends of the sightseeing vehicle; a filter, a rotating wheel type indirect evaporative cooler, a direct evaporative cooler and an air feeder are arranged in the refrigerating unit in sequence from the air inlet to the air supply opening; and a power supply control system used for providing electric energy for the rotating wheel type indirect evaporative cooler, the direct evaporative cooler and the air feeder is arranged on the refrigerating unit. According to the sightseeing vehicle based on the new energy composite air conditioning system, wind energy and solar energy are mutually adopted to generate power, and then are combined with an evaporative cooling technology to perform refrigeration.

Owner:SHANGHAI UNIV OF ENG SCI

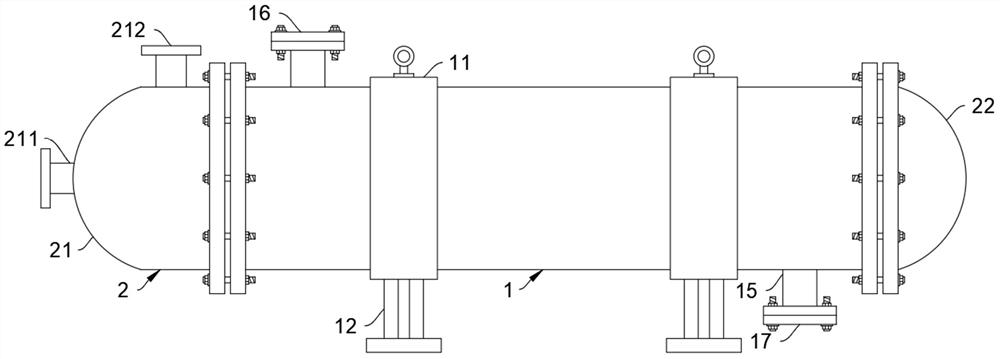

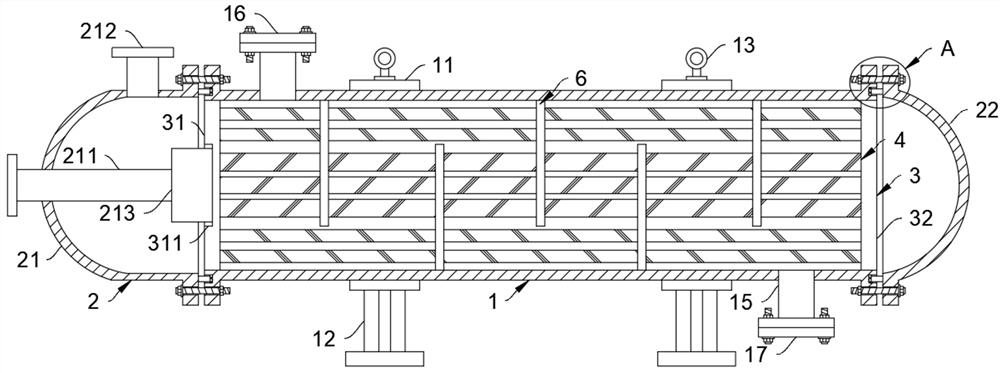

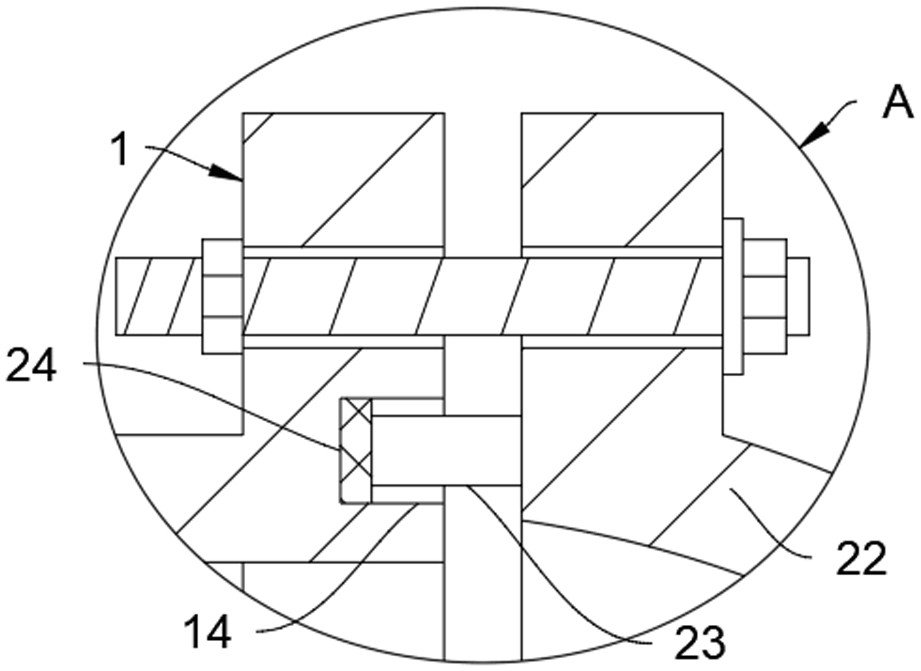

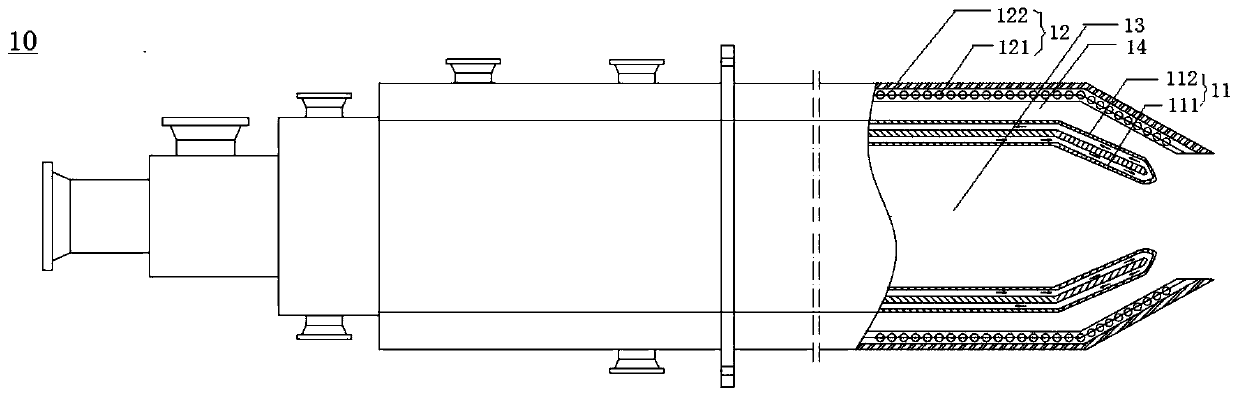

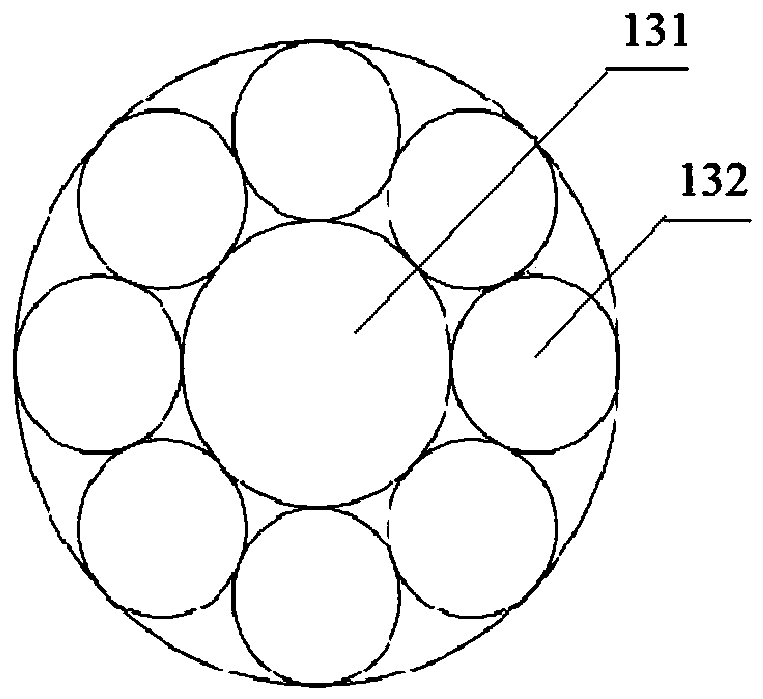

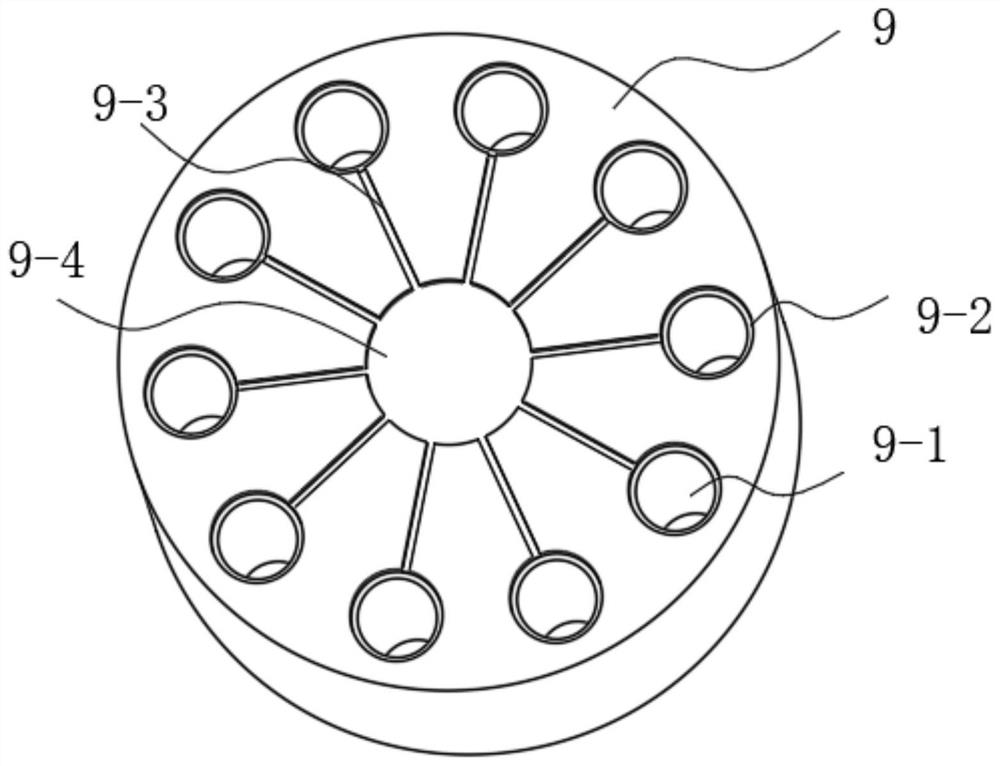

Tube plate mounting structure of quick-connection type tubular heat exchanger for chemical engineering

ActiveCN112161498AAchieve secondary coolingImprove heat transfer efficiencyHeat exchanger casingsStationary tubular conduit assembliesEngineeringSoldering

The invention belongs to the field of heat exchanger equipment, and particularly relates to a tube plate mounting structure of a quick-connection type tubular heat exchanger for chemical engineering.The tube plate mounting structure comprises a shell; a tube box is fixedly connected to the shell through a flange; tube plates are in threaded connection at the two ends, close to the tube box, of the shell; the tube box and the tube plates are arranged in a matched manner; heat exchange tubes are detachably connected to the tube plates; one end of each heat exchange tube is connected with one tube plate in a clamping manner, and the other end of the heat exchange tube is fixedly connected with the other tube plate through a limiting mechanism; and the heat exchange tubes are connected with the shell through baffle plates in a matched manner. According to the tube plate mounting structure, the heat exchange tubes which are detachably connected are arranged, the situation that normal use of equipment is affected by the condition of insufficient soldering or desoldering of welding spots in the welding process of the heat exchange tubes and the tube plates is avoided, meanwhile, workerscan effectively and conveniently conduct detection and replacement operation on the equipment, the labor intensity of the workers in the operation process is reduced, and the repair efficiency of theequipment is improved.

Owner:惠州忠信化工有限公司

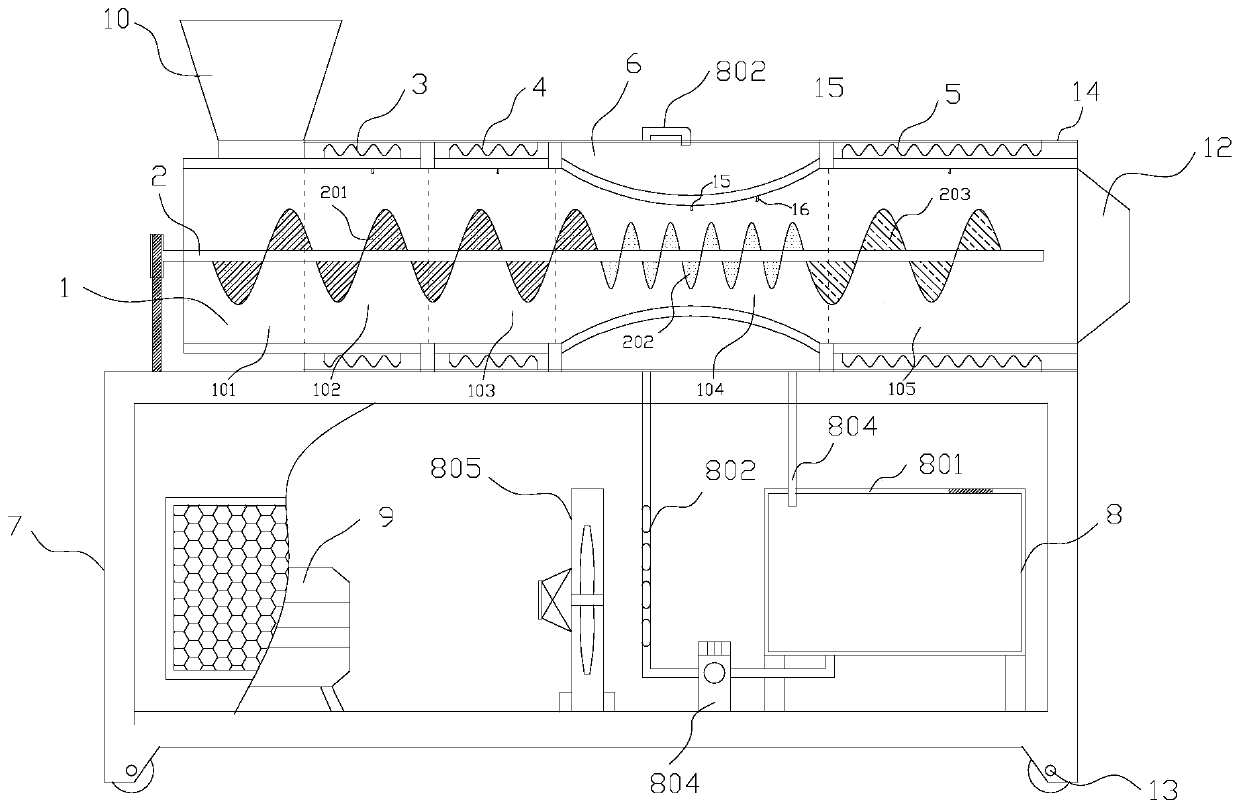

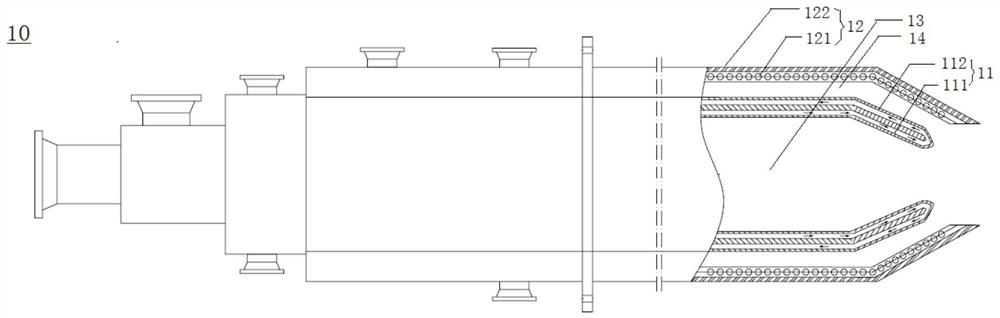

Full-automatic fireproof cable production line

PendingCN112542273AImprove roundnessImprove tensile propertiesApparatus for feeding conductors/cablesApparatus for heat treatmentProcess engineeringElectric cables

The invention provides a full-automatic fireproof cable production line. The full-automatic fireproof cable production line comprises an insulating layer automatic feeding system, a cabling system, rounding equipment and conveying equipment with an annealing function; the insulating layer automatic feeding system is used for drying and cooling a fireproof powder filler; the treated fireproof powder filler enters the cabling system for later use; the cabling system is used for cabling a fireproof cable; the rounding equipment is arranged at the downstream of the cabling system and used for rounding the fireproof cable cabled by the cabling system; the conveying equipment with the annealing function is arranged at the downstream of the rounding equipment and is used for carrying out annealing treatment on the fireproof cable rounded by the rounding equipment. According to the full-automatic fireproof cable production line, full automation of cable production is achieved, the number of operators needed by the whole production line is small, the labor intensity is greatly reduced, the production efficiency is improved, the performance of cables produced and machined in the same time ismuch higher than that of cables produced and machined in an existing method, and the quality of the machined cables is guaranteed.

Owner:GUANGDONG SHENGYU CABLES IND

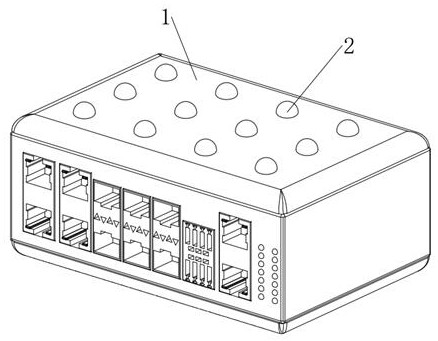

Overheating point floating Ethernet switch

ActiveCN114679637AImprove cooling efficiencyImprove exchange efficiencyCooling/ventilation/heating modificationsSelection arrangementsThermodynamicsWater flow

The invention discloses an overheat point floating type Ethernet switch, and belongs to the technical field of switches. When an overheat phenomenon occurs in the working process of a switch body, a cooling cover is pulled to expand by using the deformation action of a thermal shrinkage rod, and at the moment, cooling water in a point floating ball can enter the cooling cover through a water flowing vertical pipe; meanwhile, in the expansion process of the cooling cover, point floating balls can be pushed through water flowing vertical pipes to float upwards, on one hand, visual overheating early warning prompt can be conducted, and on the other hand, after the point floating balls move out of hemispherical floating holes, the air exchange efficiency between the outside and the exchanger body can be improved; the cooling water absorbs heat after entering the cooling cover to achieve temporary cooling, the thermal shrinkage rod recovers the shape after cooling, the cooling cover shrinks again, the cooling water absorbing heat is pressed back into the floating ball again to facilitate heat dissipation to the outside, heat can be continuously absorbed next time conveniently, and the heat dissipation efficiency of the switch body can be effectively improved.

Owner:南通睿格特智能科技有限公司

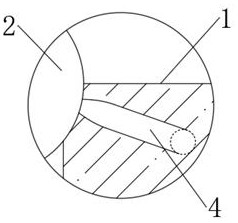

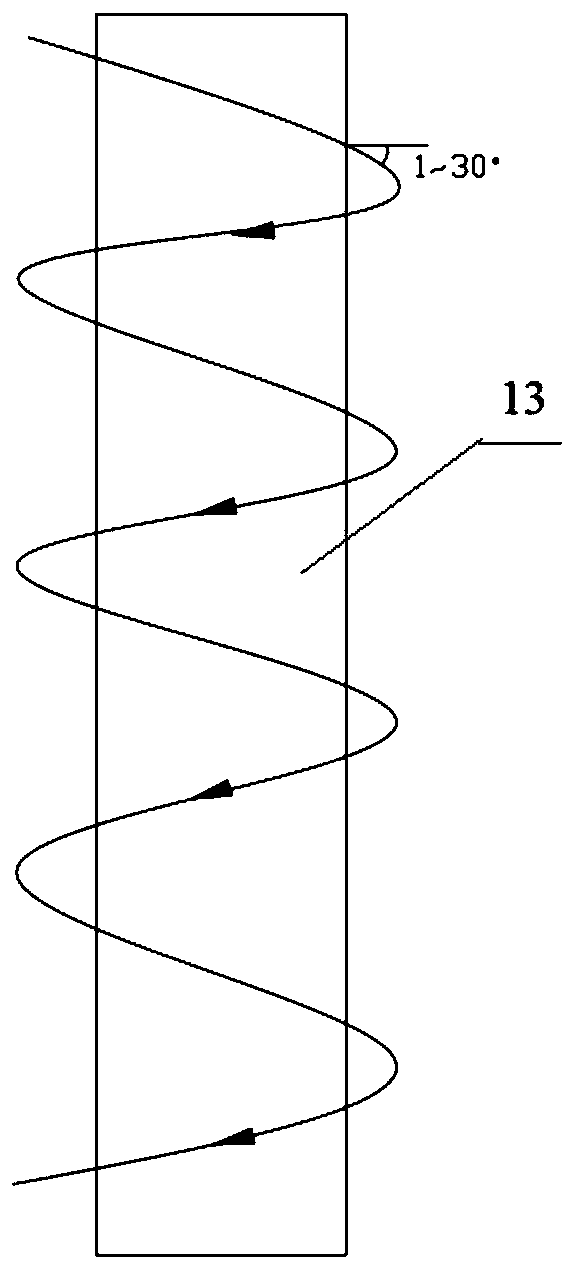

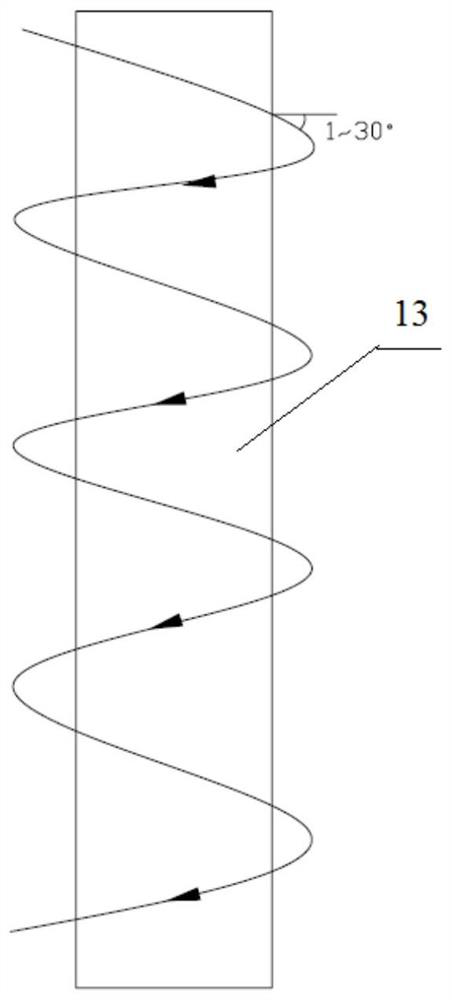

Combustion system and burner

ActiveCN110577846AAvoid softening and deformationSolve the burning problemCombustible gas productionCombustion systemCombustion

The invention belongs to the field of coal gasification combustion, and relates to a combustion system and a burner. The combustion system comprises a control system, the burner and a gasification furnace which are connected in sequence, wherein the burner comprises a cooling water jacket and an outer sleeve; the cooling water jacket is of an annular cavity structure and is arranged in the outer sleeve; the first outer wall of the cooling water jacket forms a central channel of the burner; and the second outer wall of the cooling water jacket and the inner wall of the outer sleeve form a nitrogen channel. According to the invention, the burner with a special structure and the wall of the gasification furnace are oppositely arranged at an angle of 17-20 degrees, and the rotational flow angle of the air supply outlet of the burner is controlled to be 1-30 degrees, so the problems of deviated combustion, channeling and the like of the gasification furnace can be effectively avoided.

Owner:杨建平

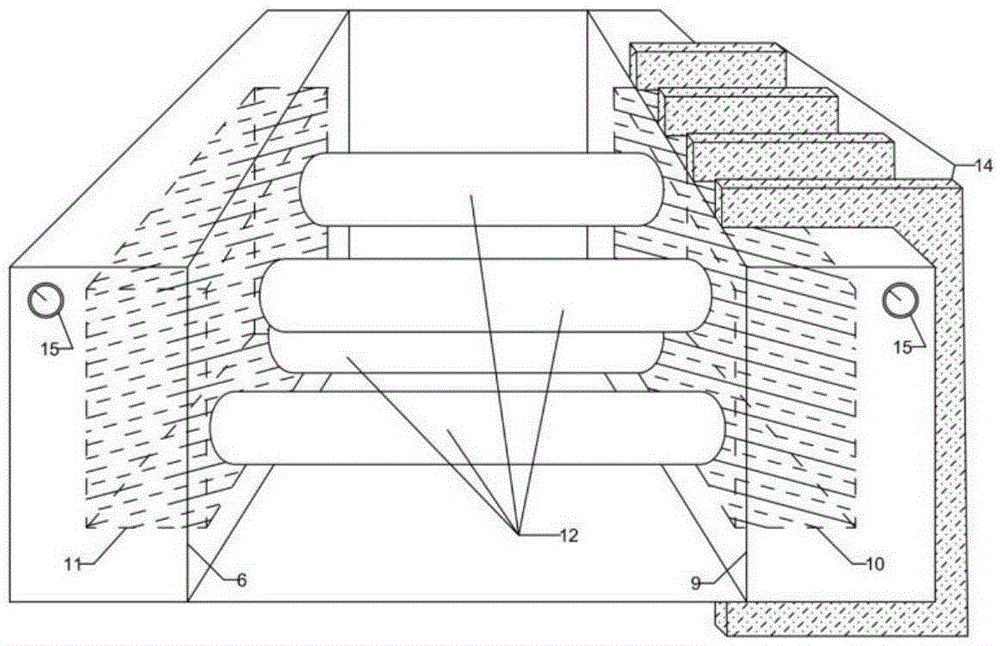

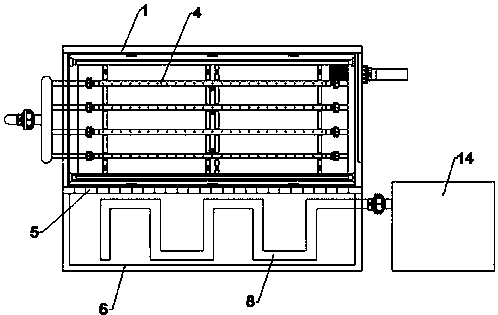

Improved high-temperature atmosphere multistage circulating cooling superhigh-temperature sintering furnace

ActiveCN107941006AAchieving first-level coolingAchieve secondary coolingFurnace typesIncreasing energy efficiencyThermodynamicsEngineering

An improved high-temperature atmosphere multistage circulating cooling superhigh-temperature sintering furnace comprises a furnace body, a gas outlet pipe, a gas inlet pipe, a first cooling device anda second cooling device. A heat screen assembly is arranged in the furnace body. The first cooling device comprises a fan, fan blades, a first coil pipe and a forced cooling tank. The fan blades arearranged in the forced cooling tank. The output end of the fan is connected with a fan blade shaft so as to drive the fan blades to rotate. The first coil pipe is arranged at the air inlet ends of thefan blades. The second cooling device comprises a second left baffle, a second right baffle and a second coil pipe. The second coil pipe is arranged between the second left baffle and the second right baffle. In the improved high-temperature atmosphere multistage circulating cooling superhigh-temperature sintering furnace, the fan in the first cooling device is used for drawing out hot gas in thefurnace body, and through cooling of the first coil pipe and the second cooling device, first-stage cooling on the gas is achieved; and the second cooling device comprises the second left baffle, thesecond right baffle and the second coil pipe, the second coil pipe achieves second-stage cooling on the gas, and therefore the cooling efficiency is improved.

Owner:NINGXIA SINCERE VACUUM EQUIP

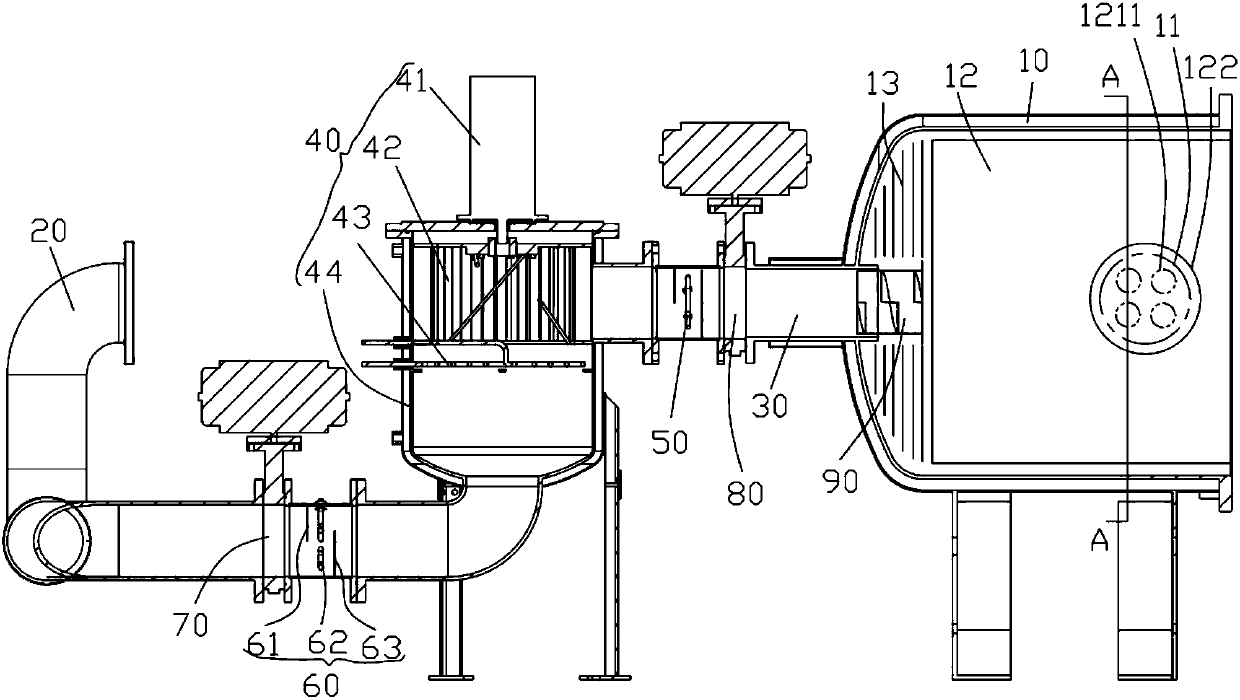

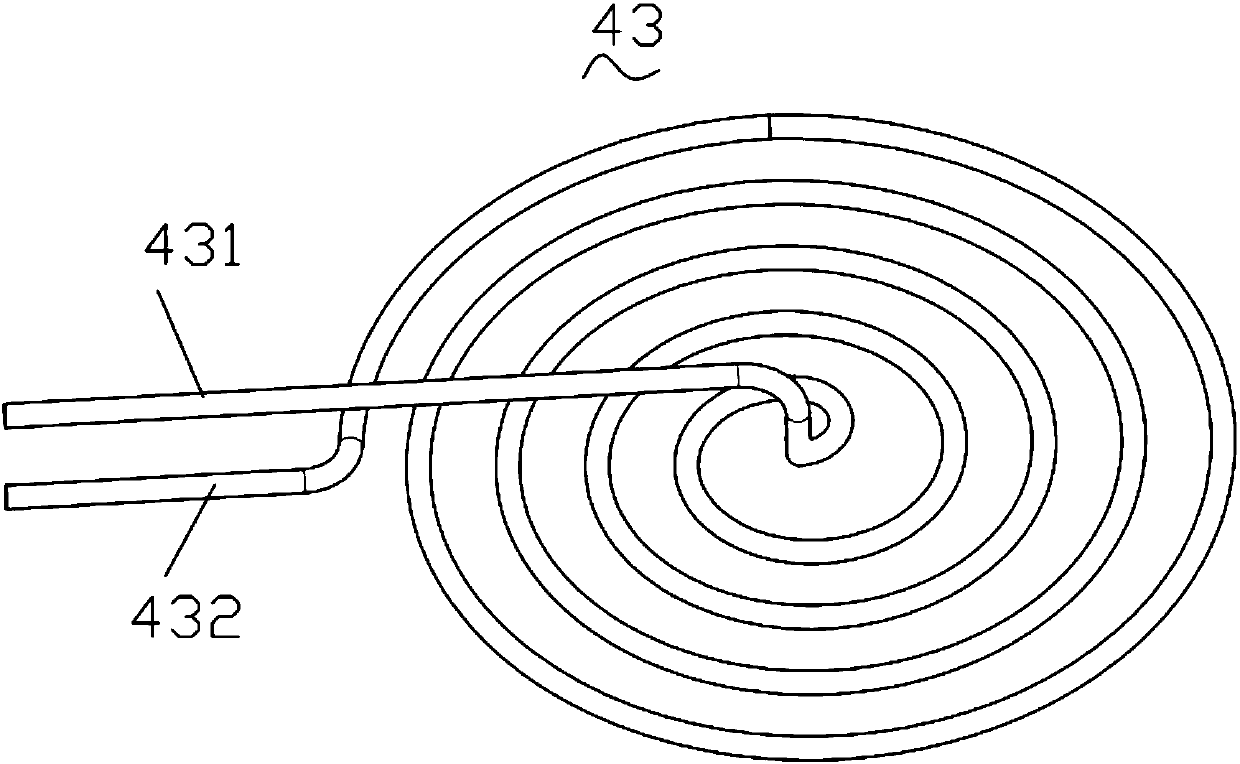

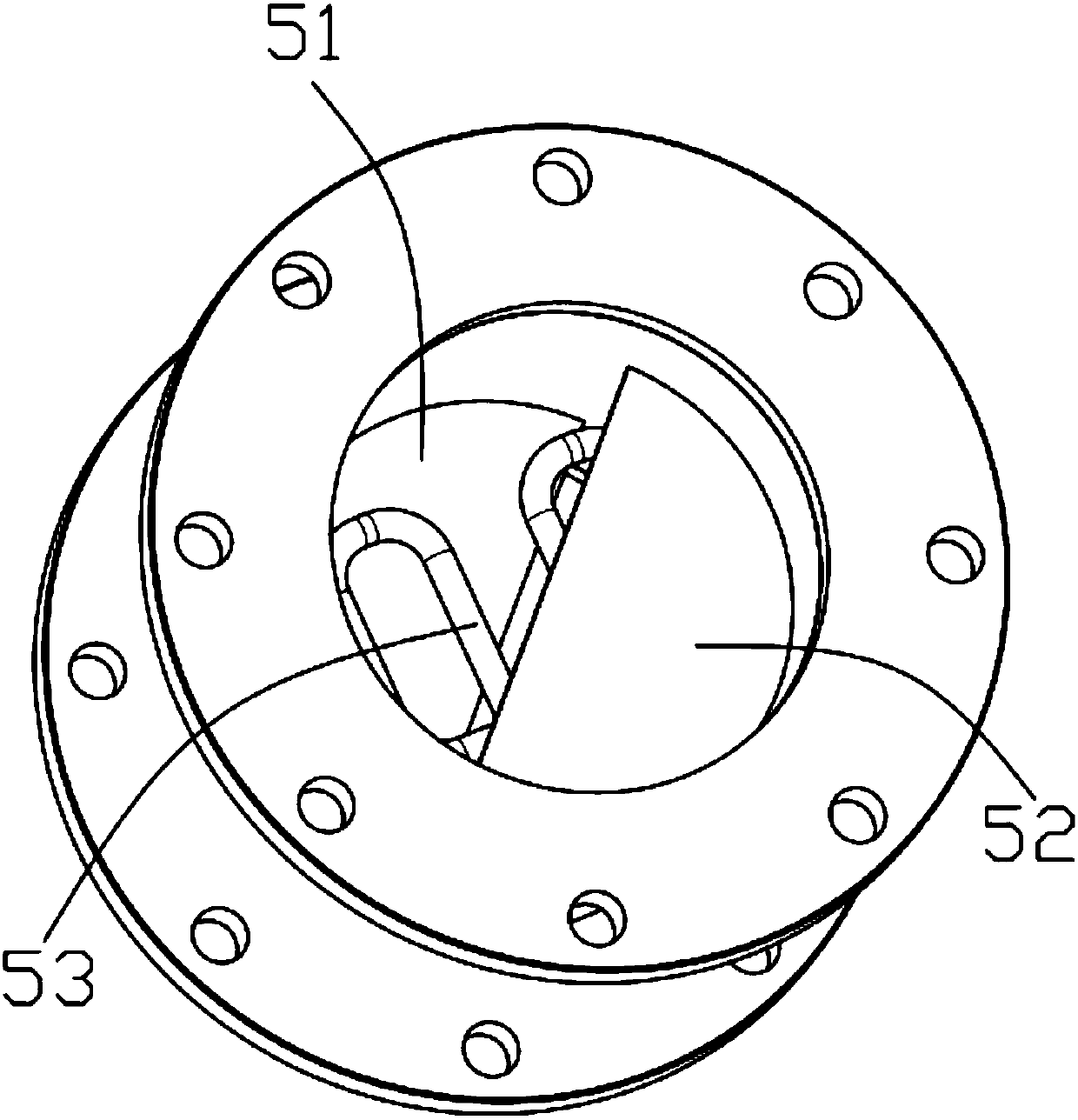

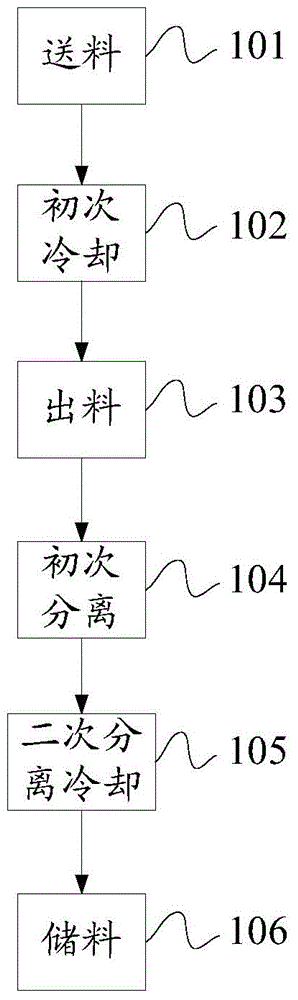

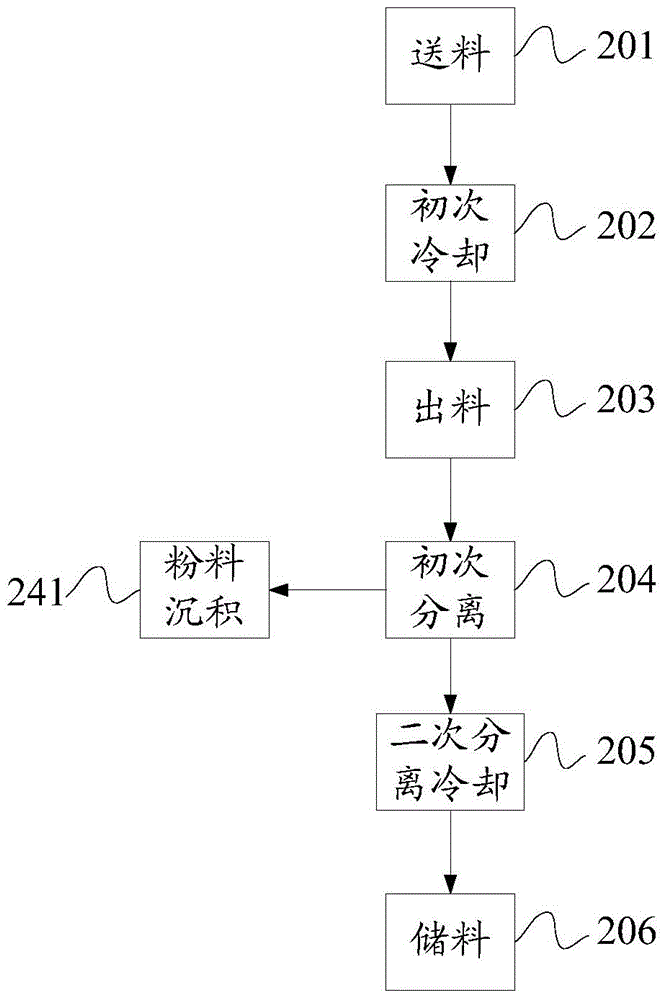

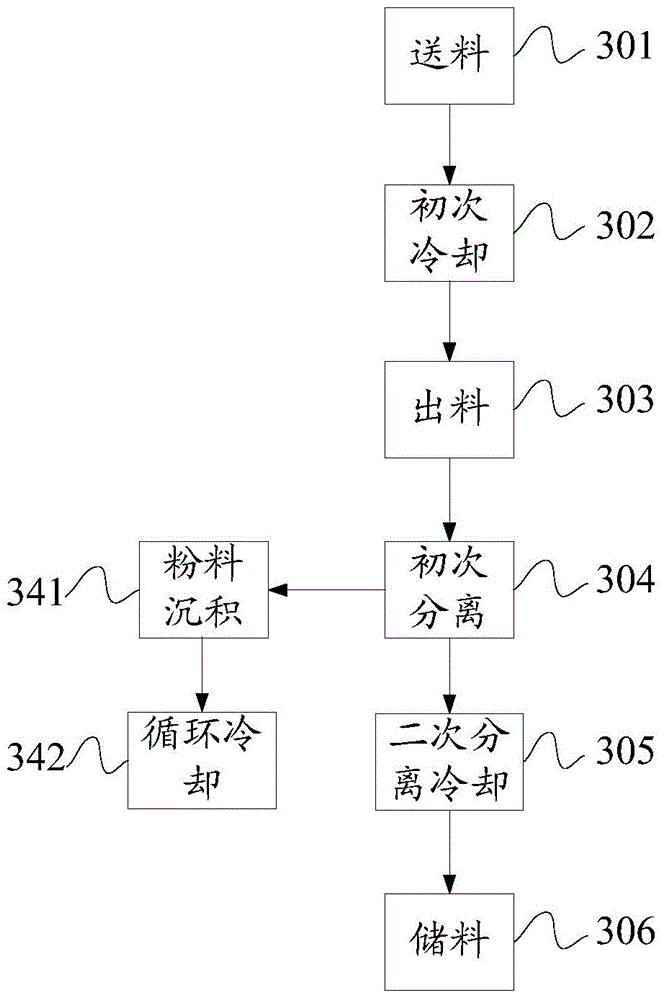

Rapid cooling method for high-temperature materials

InactiveCN104457084AImprove cooling efficiencyAchieve secondary coolingDomestic cooling apparatusLighting and heating apparatusFailure rateCooling effect

The invention discloses a rapid cooling method for high-temperature materials. By means of the feed step, the primary cooling step, the discharge step, the primary separation step, the secondary separation and cooling step and the material storage step which are sequentially conducted, the first-time cooling is conducted on the high-temperature materials through cooling water, the second-time cooling of the materials is achieved by evaporating residual water through the waste heat of the materials, the whole material cooling efficiency is high, the cooling effect is good, the requirements for the texture and the high temperature tolerance of subsequent devices are low, and the maintenance cost and the failure rate of related devices can be accordingly decreased.

Owner:SHANDONG IRON & STEEL CO LTD

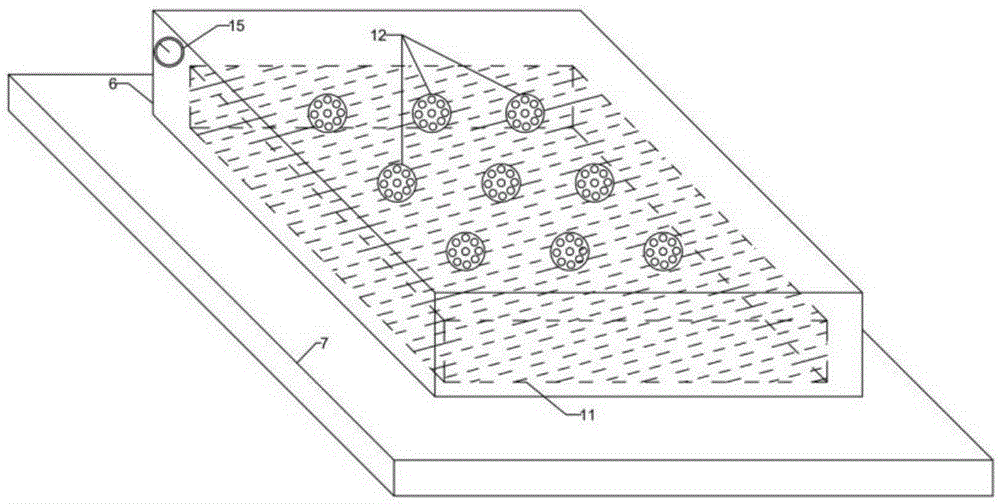

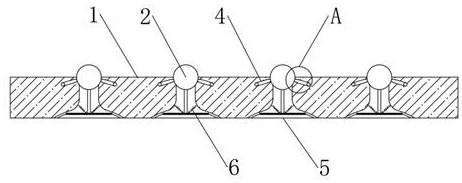

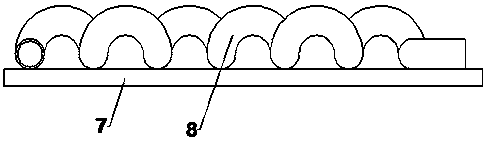

Reaming groove for wet black silicon machine and reaming method of reaming groove

ActiveCN107681021AAchieve secondary coolingGuarantee product qualityFinal product manufactureSemiconductor devicesChemical solutionEngineering

The invention discloses a reaming groove for a wet black silicon machine and a reaming method of the reaming groove. The reaming groove comprises a main groove, an auxiliary groove, a cold-heat exchanger and a liquid guide tube for forming a liquid flow circuit; design of the main groove and the auxiliary groove is mainly used for releasing certain heat after reaction of a silicon wafer is completed, so that overflowing liquid medicine is effectively cooled through the design of capillary tubes in the auxiliary groove; meanwhile, the cold-heat exchanger is also arranged, so that secondary cooling for the liquid medicine is achieved and the preparation quality of black silicon is effectively ensured; and the liquid medicine overflows into the auxiliary groove from the main groove, and meanwhile, the liquid medicine is conveyed through liquid inlet pipes in which a plurality of liquid outlet holes are distributed, so that the uniformity of a chemical solution is ensured to the maximum extent.

Owner:无锡琨圣智能装备股份有限公司

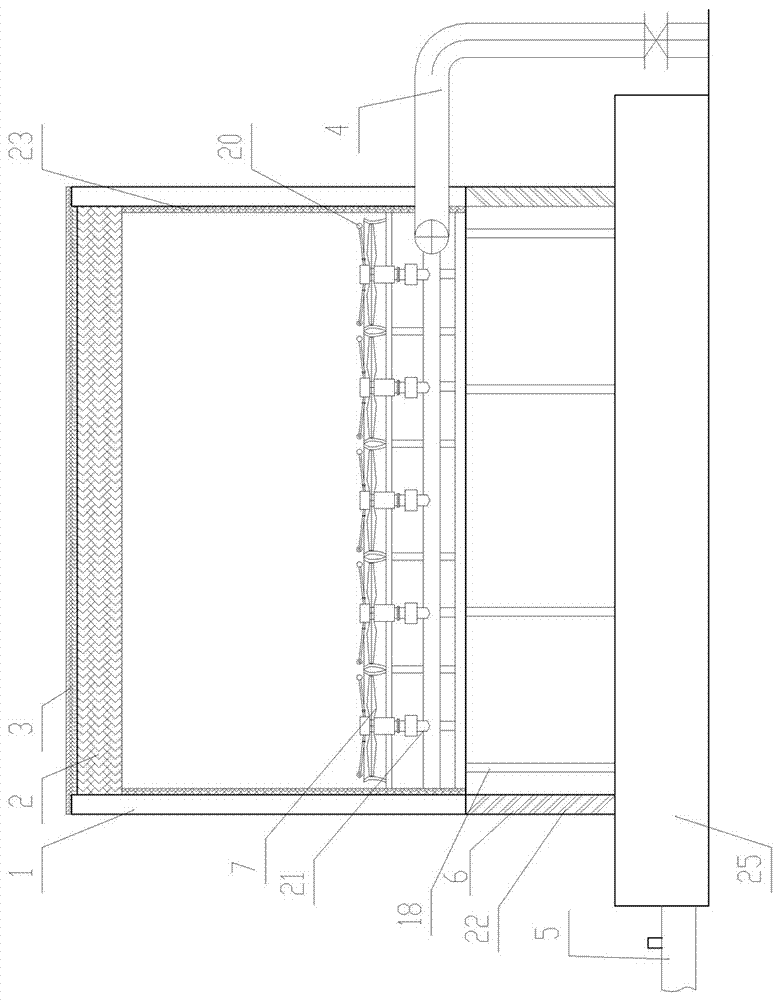

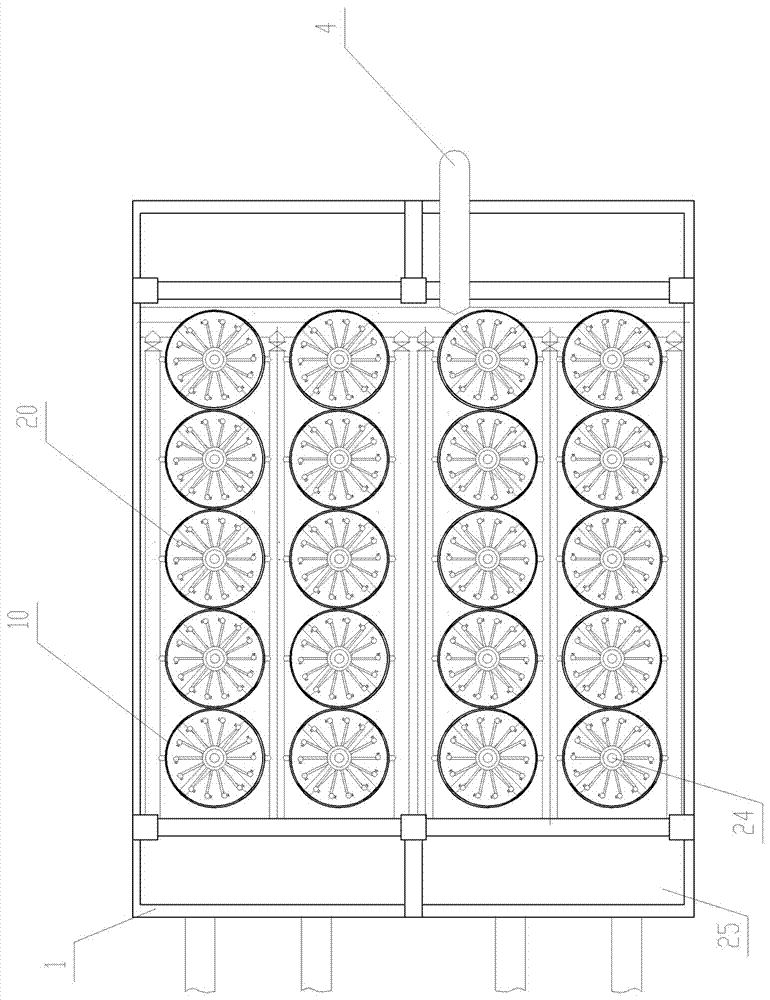

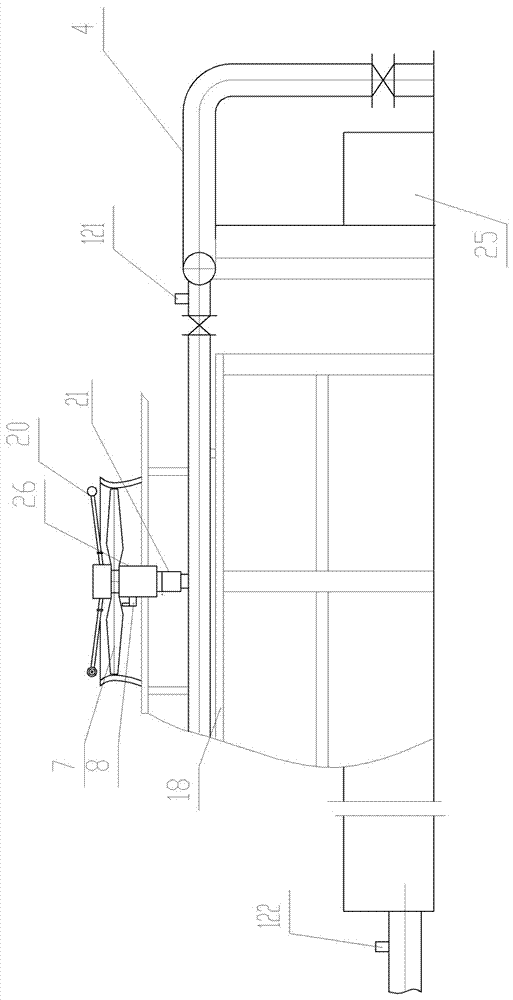

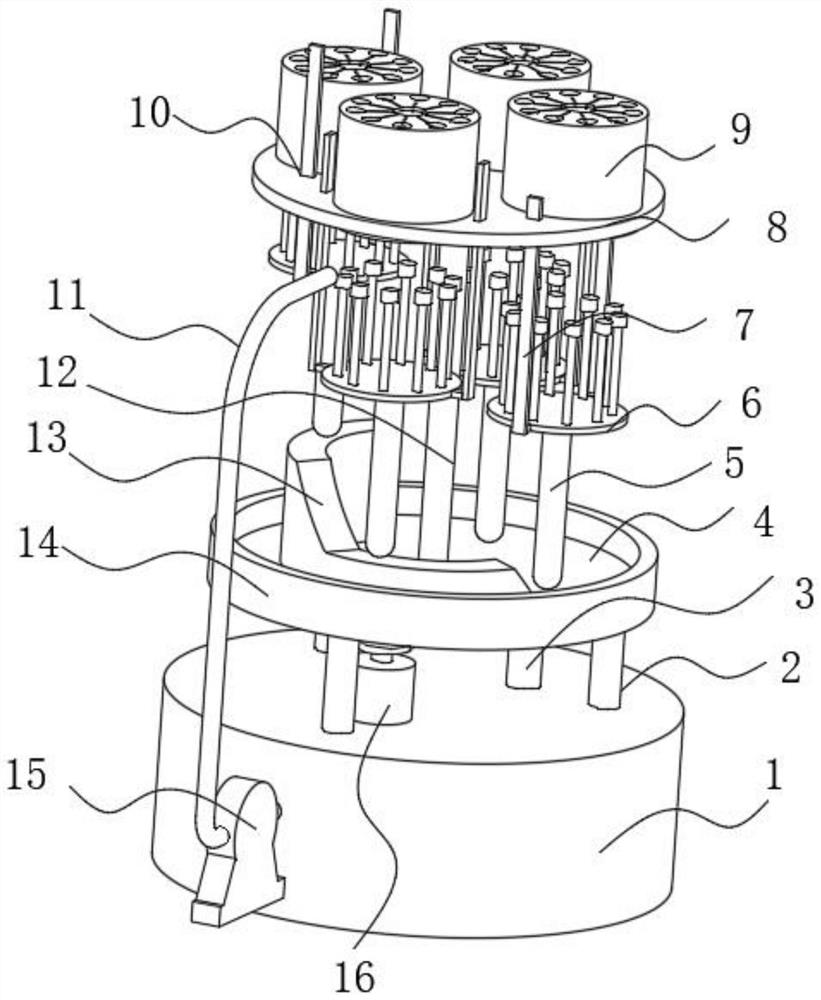

Intelligent atomization cooling tower device and control method thereof

PendingCN107504831AReduce resistanceImprove cooling effectHeat exchange apparatusTrickle coolersCold airAutomatic control

The invention discloses an intelligent atomization cooling tower device and a control method thereof. The intelligent atomization cooling tower device comprises a tower body, atomization modules arranged in the tower body, and an intelligent control system, wherein the tower body is equipped with a water inlet pipe and a water outlet pipe; each atomization module comprises an atomization device and an atomization push device; each atomization device comprises an atomization spray head and an atomization water inlet pipe, one end of each atomization water inlet pipe communicates with the corresponding atomization spray head, and the other end of the atomization water inlet pipe communicates with the water inlet pipe; each atomization push device is provided with a sensing component, a pressurization device and a fan blade, each pressurization device is connected with the corresponding atomization water inlet pipe and pressurizes the corresponding atomization spray head, and each fan blade is arranged at the lower end of the corresponding atomization spray head and driven by the reaction thrust generated through the injection of the corresponding atomization spray head, so that cold air enters a tower to carry out heat exchange with atomization water drops; and the intelligent control system is further arranged, and comprises a control mainframe PLC, an automatic control circuit and the sensing components, the running parameters of the cooling tower and the atomization modules, which are acquired by the sensing components, are transmitted to the control mainframe PLC through the automatic control circuit, and the cooling tower is controlled through the control mainframe PLC.

Owner:HANGZHOU FUDING ENERGY SAVING TECH SERVICE

Air-water cooling circulation system with water pool and pore plate tray

PendingCN112325550AIncrease water temperature differenceImprove cooling effectDirect contact heat exchangersCooling fluid circulationWater sourceEnvironmental engineering

The invention discloses an air-water cooling circulation system with a water pool and a pore plate tray. The air-water cooling circulation system comprises heat dissipation equipment, a connecting airduct, air-water cooling equipment, the water pool, a water pump, a water tower and an external water source; and an outlet of the heat dissipation equipment communicates with the air side of the air-water cooling equipment through the connecting air duct, an outlet of the water pool communicates with a water side inlet of the air-water cooling equipment through the water pump, a water side outletof the air-water cooling equipment communicates with an inlet of the water tower, and the pore plate tray is arranged at a bottom outlet of the water tower, wherein the water pool is located under the pore plate tray, a cooling fan is arranged at the bottom of the water tower, and an external water source communicates with the water pool. According to the system, the temperature difference between supplied water and returned water can be effectively increased.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

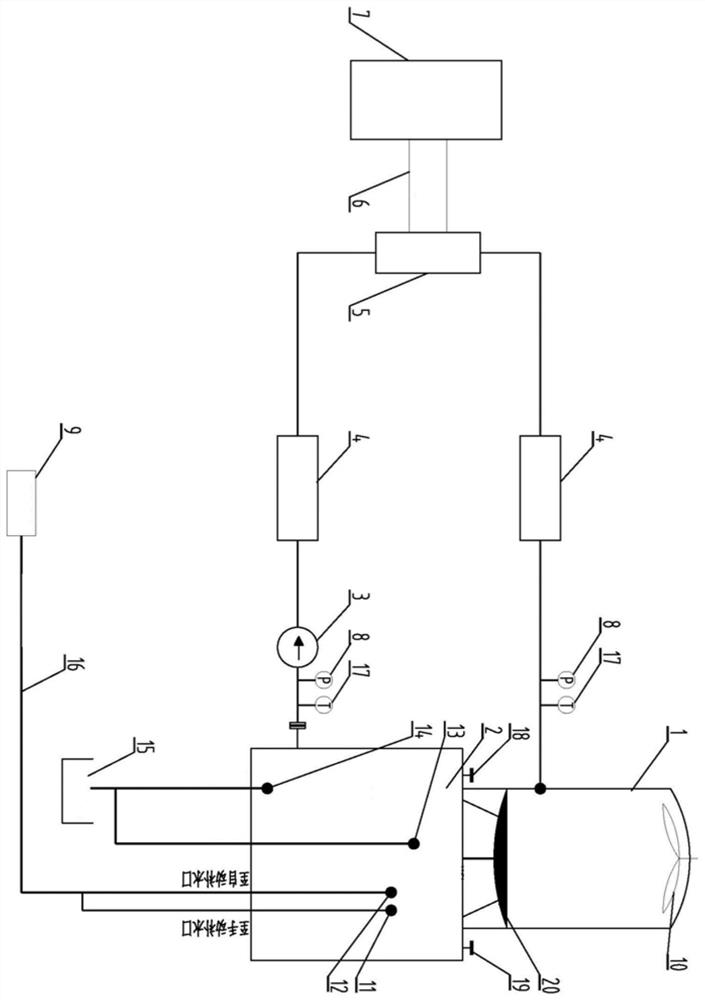

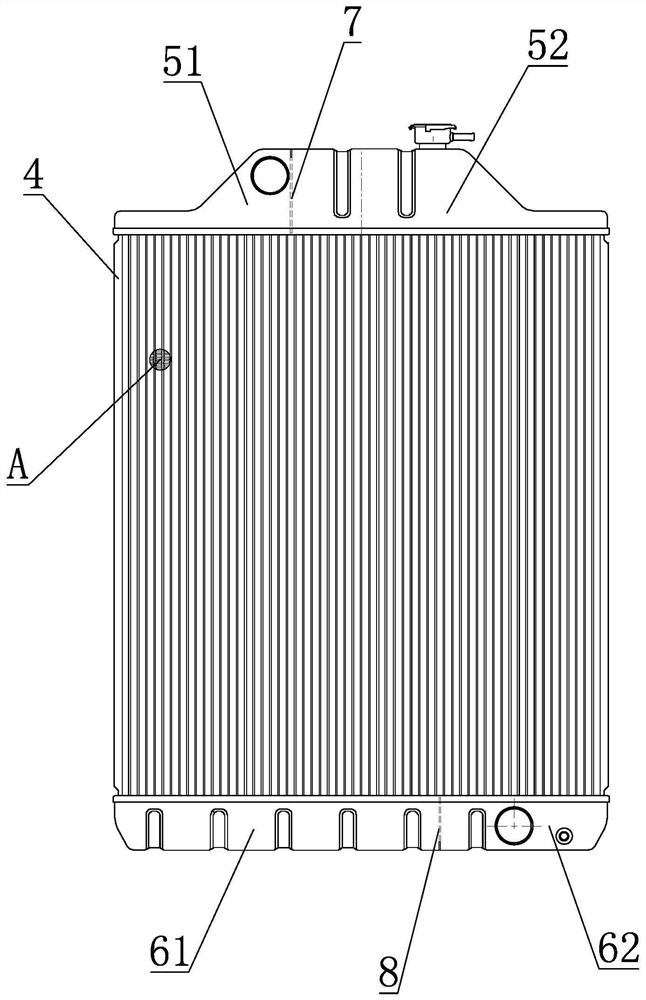

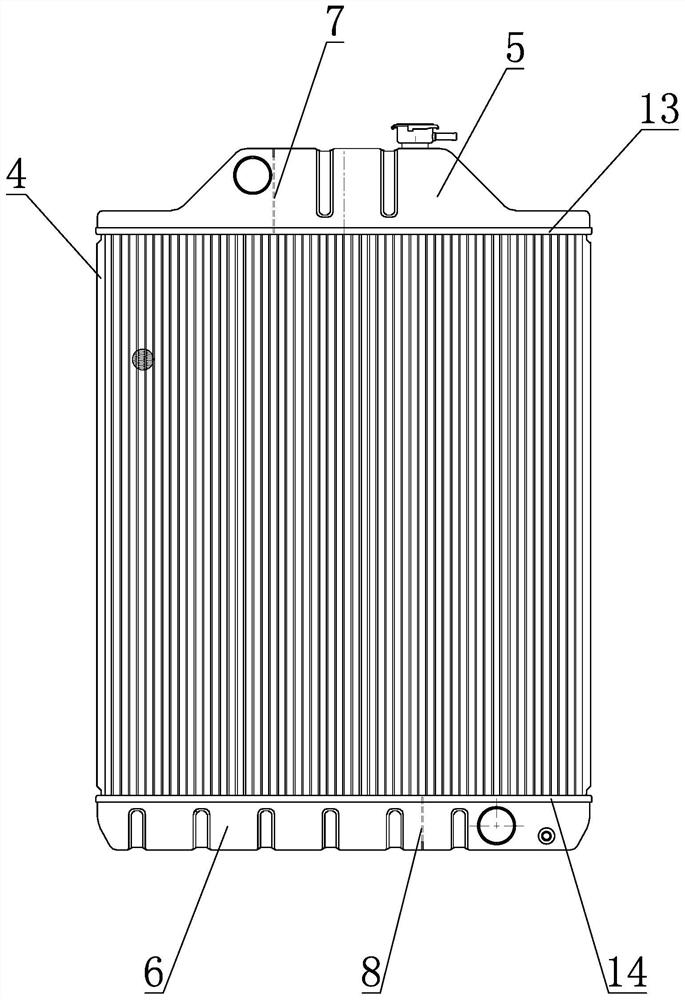

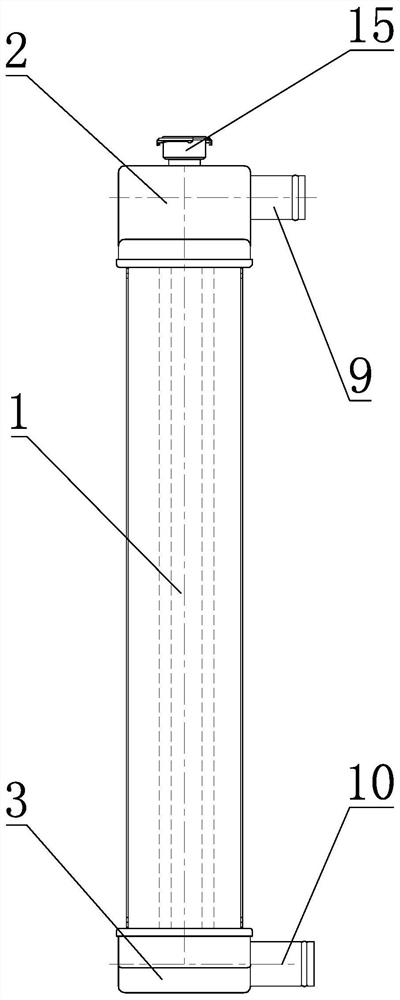

Water radiator

PendingCN113390273AImprove cooling efficiencyAchieve secondary coolingStationary conduit assembliesHeat exchanger casingsEngineeringEnvironmental geology

A water radiator aims to solve the technical problem that in the prior art, high-temperature fluid in an upper water chamber and low-temperature fluid in a lower water chamber do not exchange heat with the outside basically, so that the radiating efficiency of a radiator is low. The water radiator comprises a radiating core, an upper water chamber assembly and a lower water chamber assembly are arranged at the two ends of the radiating core respectively, a side plate used for packaging the radiating core is arranged between the upper water chamber assembly and the lower water chamber assembly, the upper water chamber assembly comprises an upper water chamber used for containing high-temperature fluid, and the lower water chamber assembly comprises a lower water chamber used for containing low-temperature fluid. The upper water chamber and the lower water chamber can exchange fluid with the radiating core, an upper water chamber partition plate is arranged in the upper water chamber, and a lower water chamber partition plate is arranged in the lower water chamber.

Owner:HUANGSHAN KENENG AUTO RADIATOR

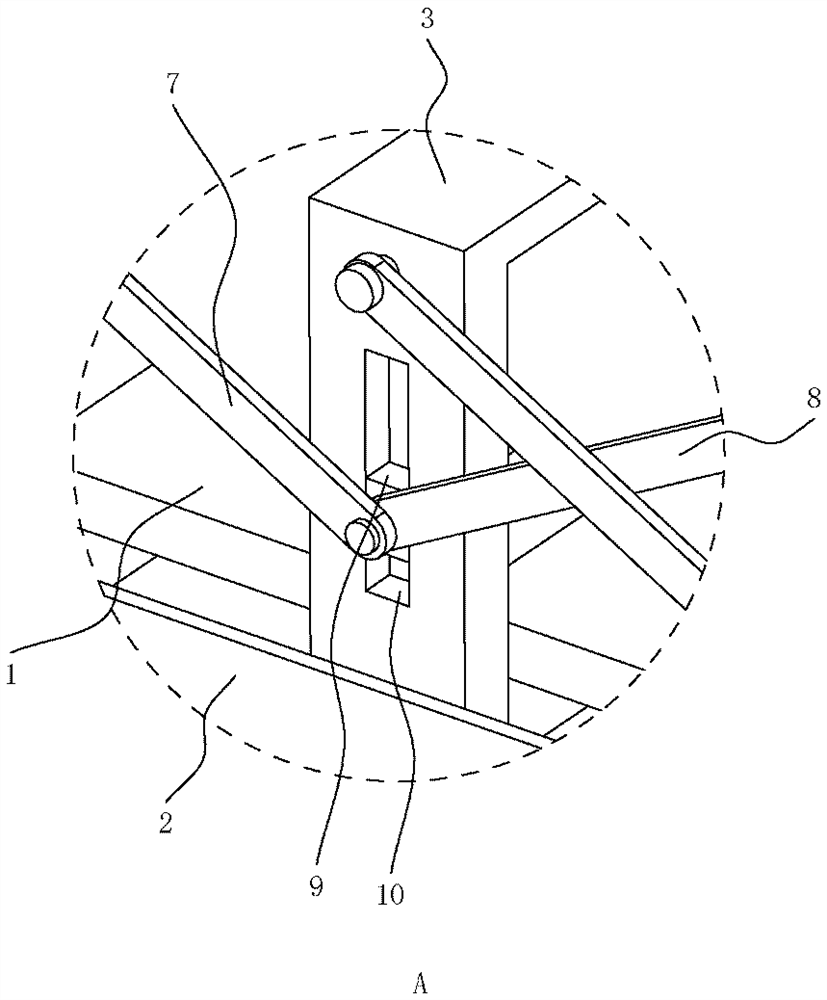

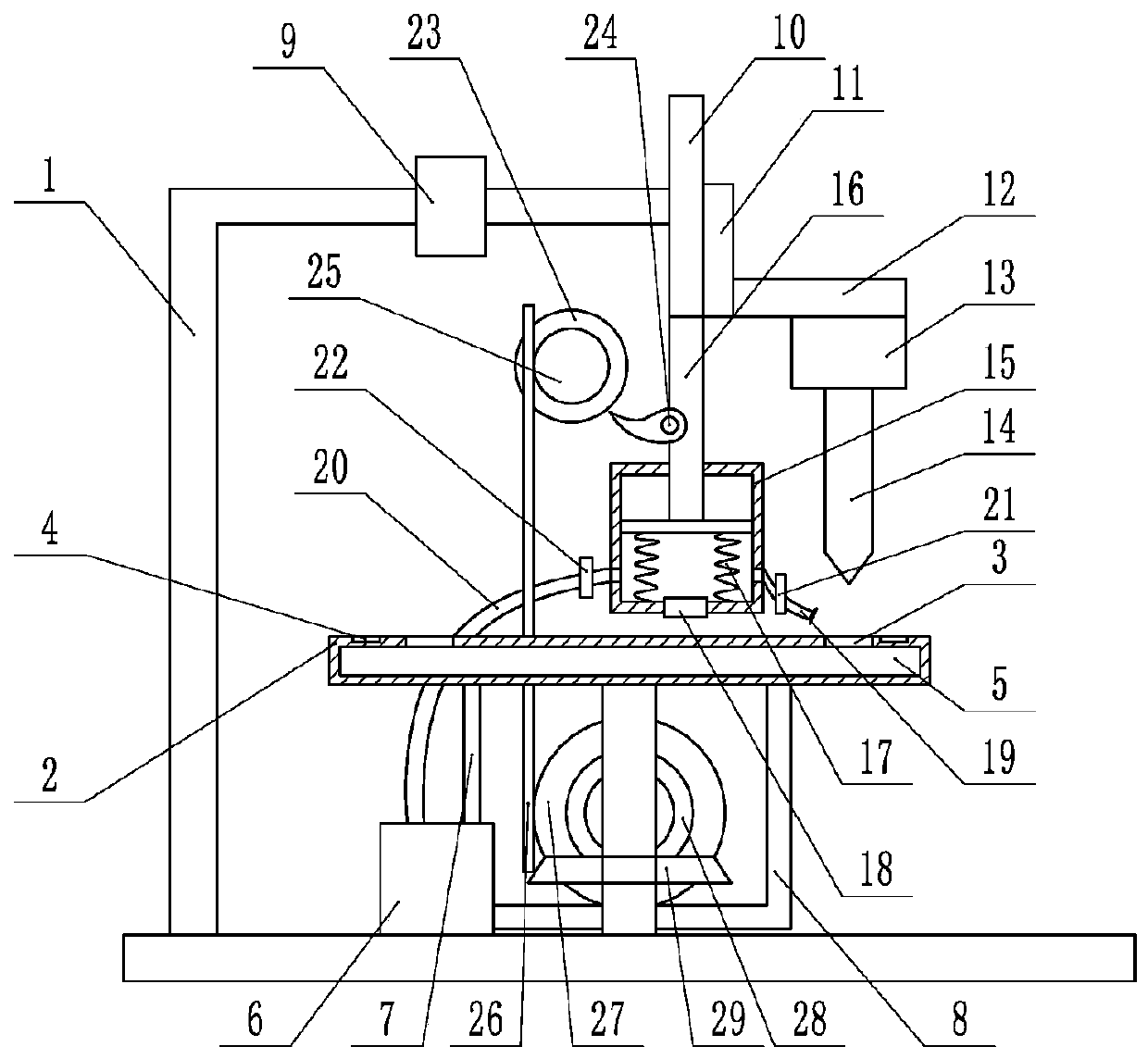

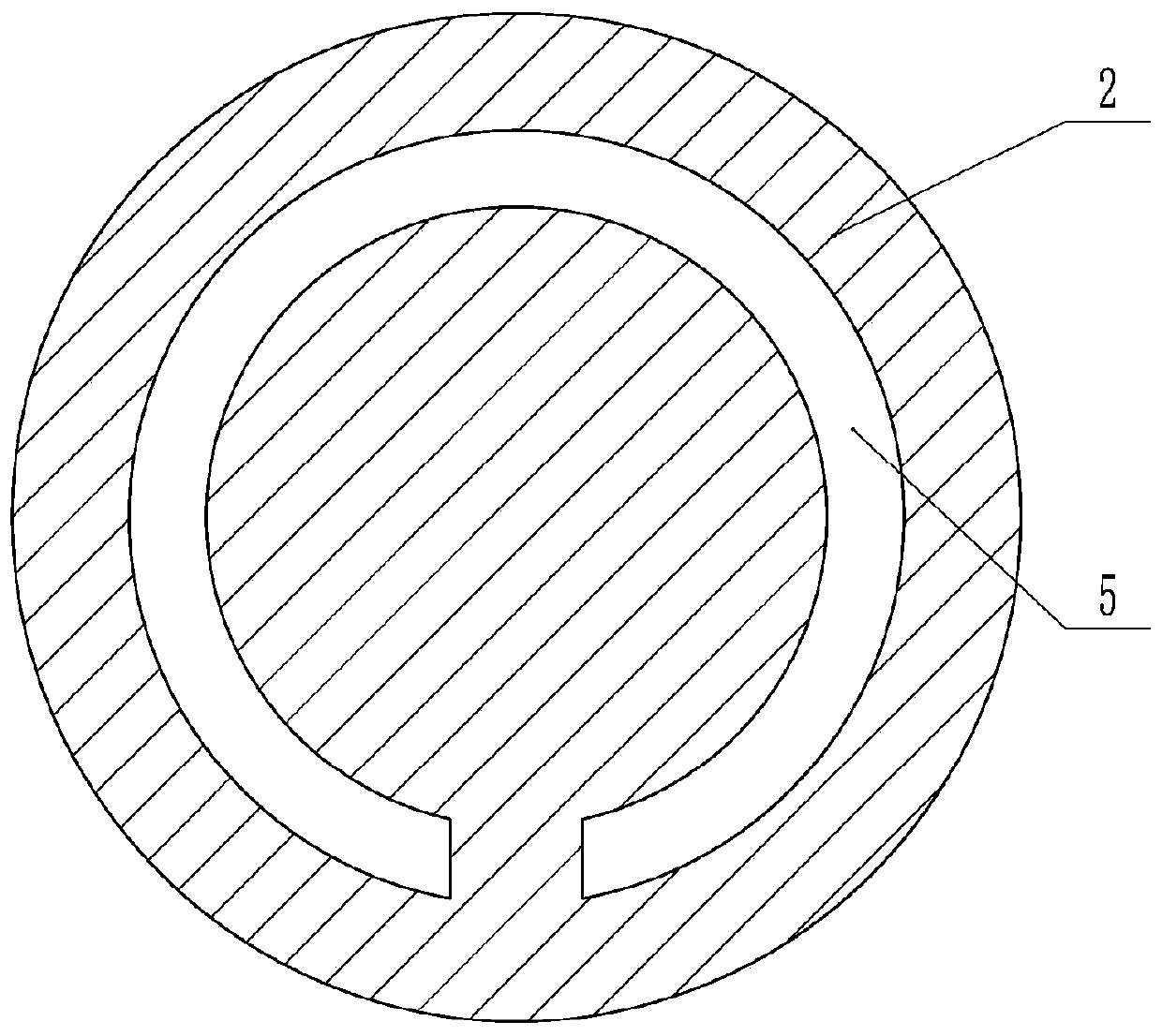

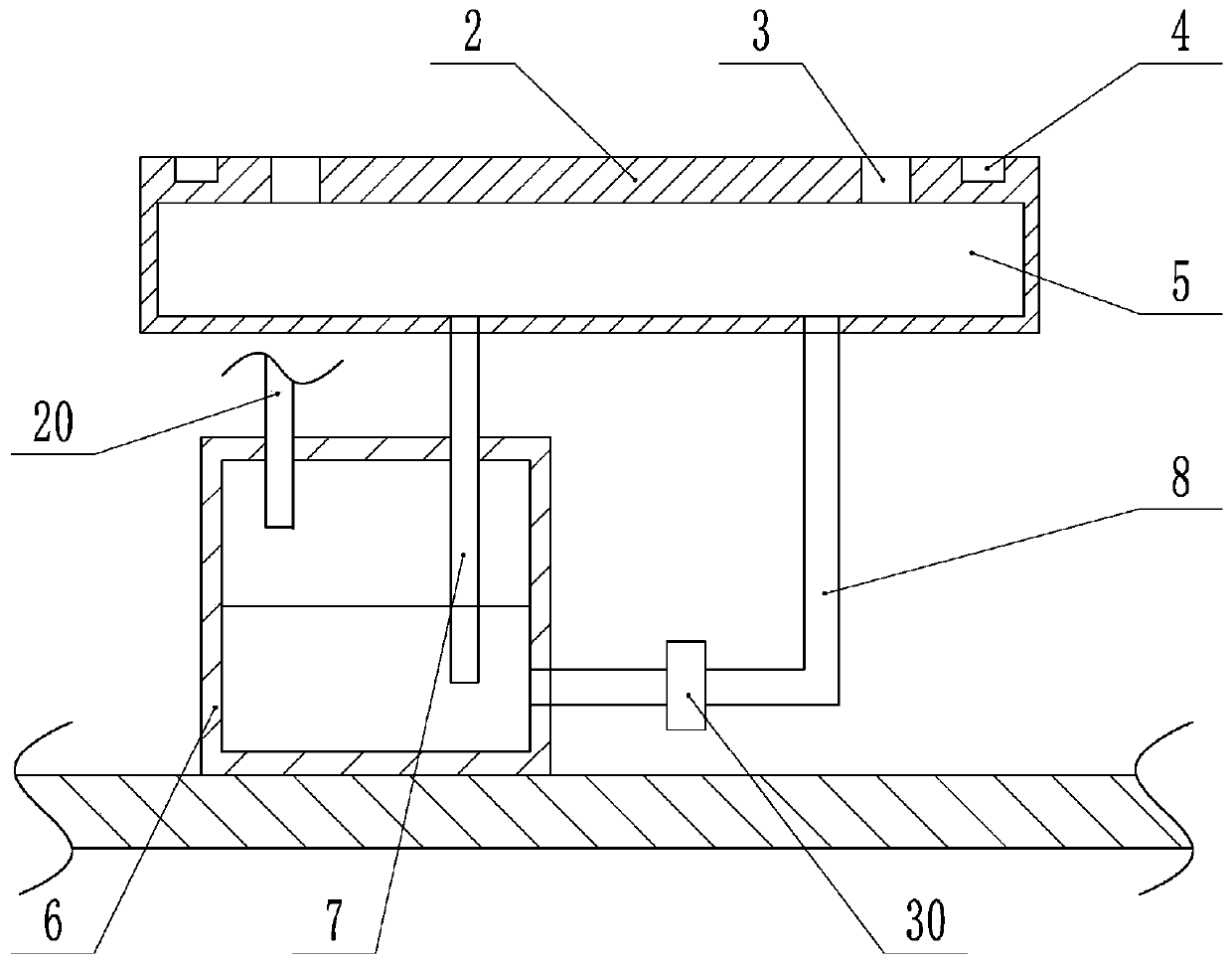

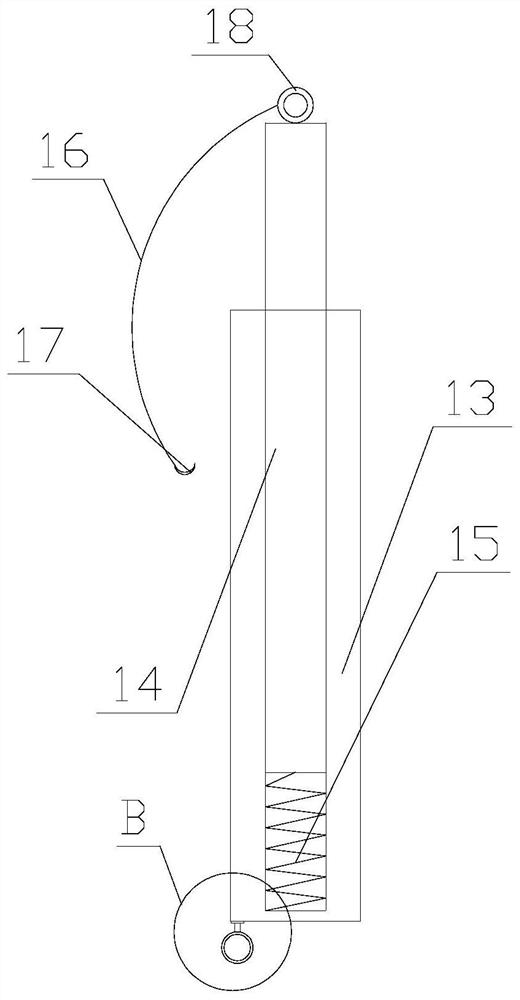

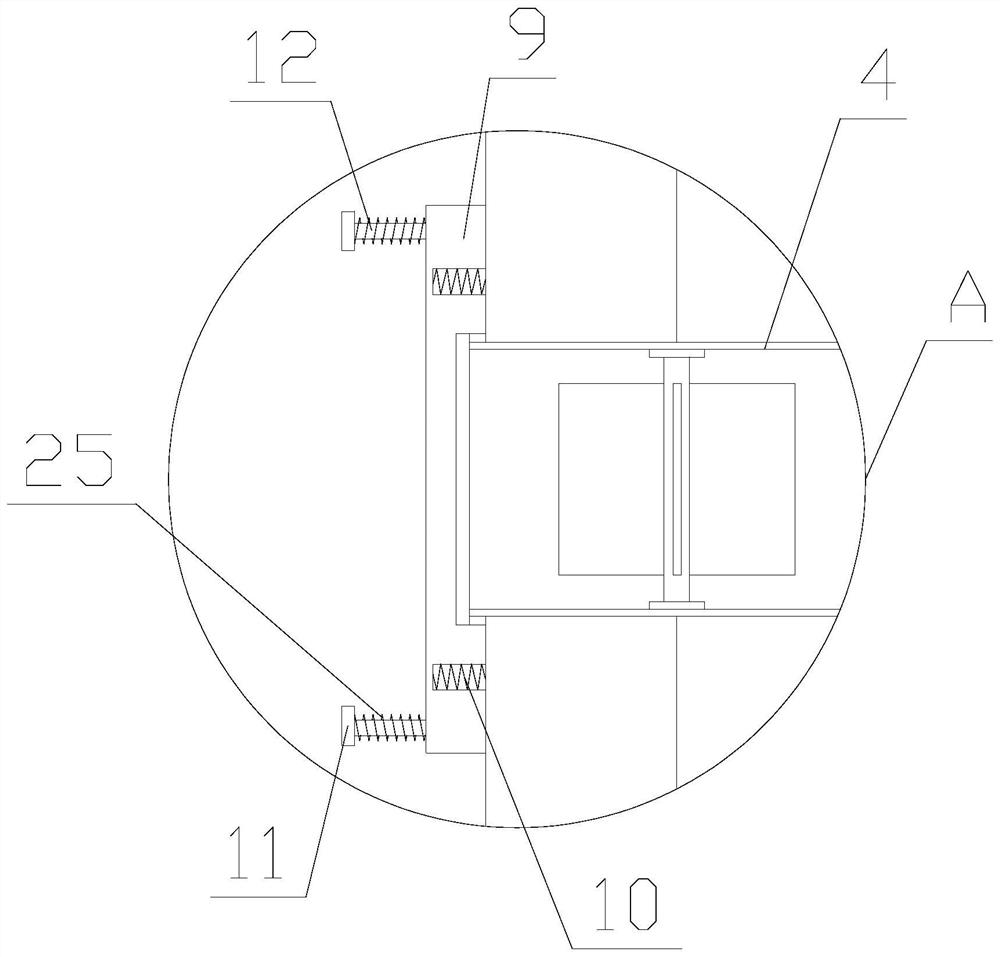

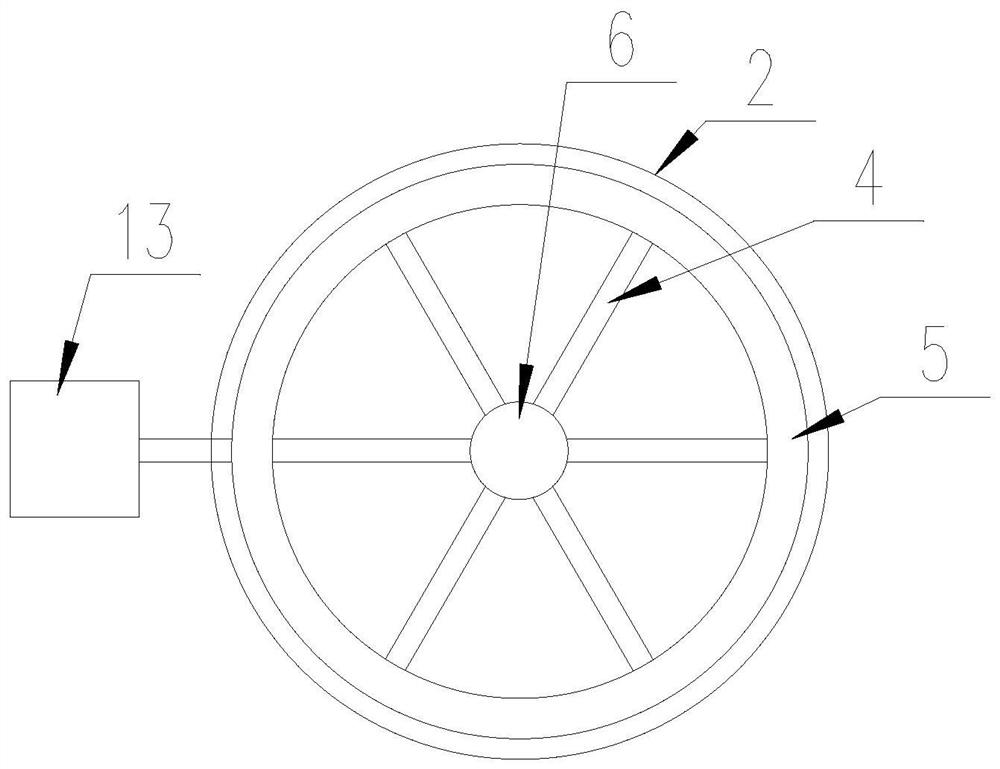

Auto parts punching device

ActiveCN108526520BSave spaceAchieve rotationPrecision positioning equipmentLarge fixed membersRatchetGear wheel

The invention belongs to the technical field of processing holes in metal products, and particularly relates to an automobile accessory perforating device. The device comprises a rack, the rack is fixedly provided with a first motor and further rotationally connected with a workbench, the workbench is provided with a preformed hole, the output shaft of the first motor is fixedly connected with a cam with which a connecting rod is fixedly connected, a connecting block is fixedly connected with the connecting rod, a second motor is fixedly arranged on the connecting block, a drill bit is fixedlyconnected with the output shaft of the second motor, the rack is further fixedly provided with a piston cylinder, a spring is connected between a piston and an inner wall of the piston cylinder, a pawl is further arranged on a piston rod, a ratchet wheel is rotationally connected with the rack, a first gear is coaxially connected with the ratchet wheel, a gear rack is meshed with the first gear,a second gear is meshed with the gear rack, the second gear is coaxially connected with a first bevel gear, and a second bevel gear, which is coaxially connected with the workbench, is meshed with thefirst bevel gear. By adopting the technical scheme, holes can be uniformly drilled in the circumferential direction in a workpiece, and the automobile accessory perforating device is mostly used fordrilling holes in the circumferential direction in the workpiece.

Owner:宁波隆锐机械制造有限公司

Metal processing auxiliary equipment

InactiveCN112128888AAchieve purificationAchieve primary coolingCombination devicesLighting and heating apparatusAir compressionMetal machining

The invention relates to metal processing auxiliary equipment. The metal processing auxiliary equipment comprises a fixed box, a cooling box, a corrugated pipe, a connecting pipe, a driving mechanism,a sealing mechanism and a switching mechanism, the driving mechanism comprises an air pump, an air inlet pipe, a one-way valve and an air outlet pipe, the sealing mechanism comprises a sealing plateand a sealing assembly, and the switching mechanism comprises a connecting plate, a moving plate and a second spring. According to the metal processing auxiliary equipment, air blowing in the fixed box is achieved through the driving mechanism, the air pressure in the fixed box is increased, meanwhile, air purification and primary cooling of air are achieved, when the air pressure reaches a presetvalue, the air in the fixed box enters the cooling box through the connecting pipe, air compression is achieved, and therefore secondary cooling of the air is achieved; three-stage cooling of the airis achieved through the cooling mechanism in the cooling box, comfort is improved, opening and closing of the corrugated pipe are achieved through the switching mechanism, flowing of the air in the cooling box is achieved, and use practicability is improved.

Owner:SHENZHEN XIAOKONG COMM TECH CO LTD

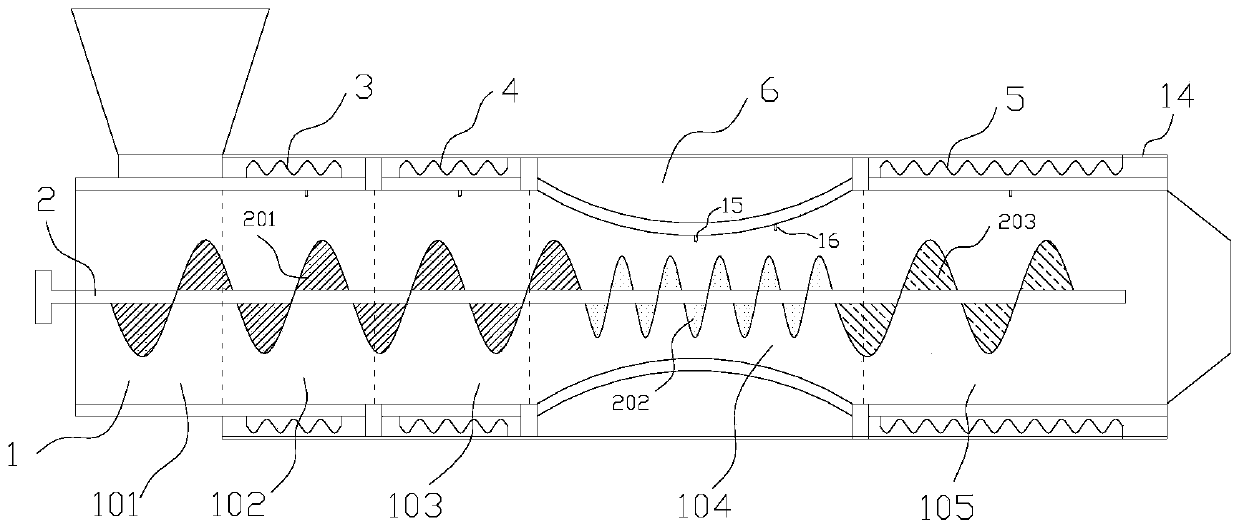

Extrusion-screw puffing cavity structure

ActiveCN110101014ARealize the second heatingFully gelatinizedFood scienceElectrical resistance and conductanceCavity wall

The invention provides an extrusion-screw puffing cavity structure. The structure comprises a puffing cavity and a screw accommodating in the cavity and is characterized in that the puffing cavity comprises a feeding conveying cavity, a first-segment high-temperature heating cavity, a second-segment high-temperature heating cavity, a low-temperature heating cavity and a third-segment high-temperature heating cavity which are distributed from a feeding end to a discharging end in sequence; a first-segment high-temperature heating resistance wire, a second-segment high-temperature heating resistance wire and a third-segment high-temperature heating resistance wire are arranged outside the cavity walls of the first-segment high-temperature heating cavity, the second-segment high-temperature heating cavity and the third-segment high-temperature heating cavity respectively, a refrigerant cavity is formed outside the cavity wall of the low-temperature heating cavity, and cavity wall of the low-temperature heating cavity is sunken inwards to be provided with a material passage the diameter of which is gradually decreased at first and then gradually increased. The cavity structure comprises the four segments of heating cavities including the first-segment high-temperature heating cavity, the second-segment high-temperature heating cavity, the low-temperature heating cavity and the third-segment high-temperature heating cavity, in this way, materials discharged from the cavity structure are subjected to heating processes of temperature increasing, temperature decreasing, temperatureincreasing and temperature decreasing, secondary temperature increasing and secondary temperature decreasing of the materials can be achieved, and puffed products with better quality are convenientlyobtained.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

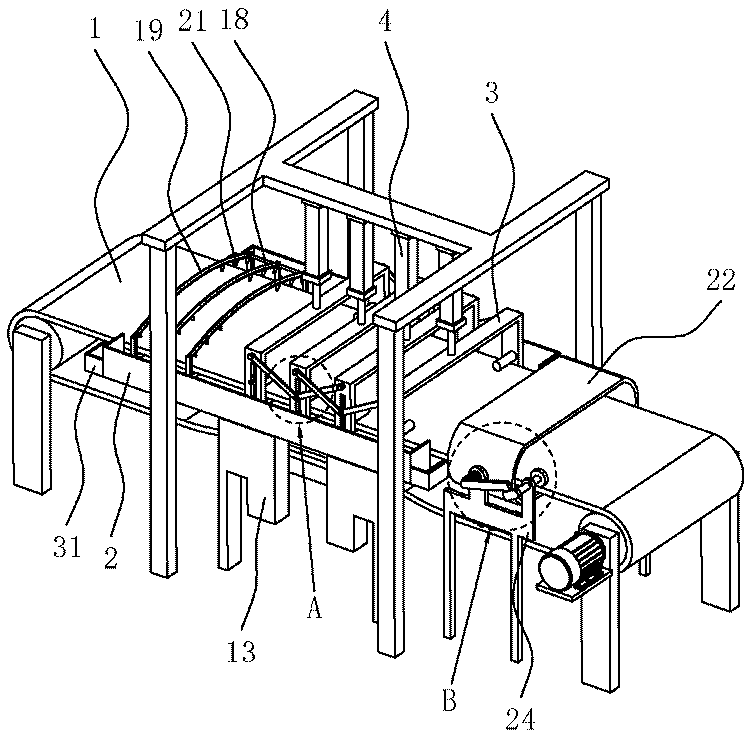

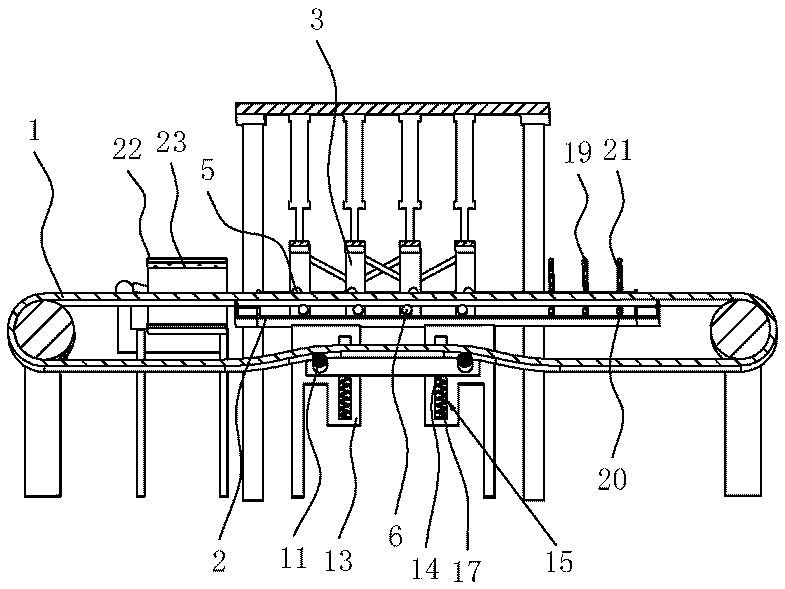

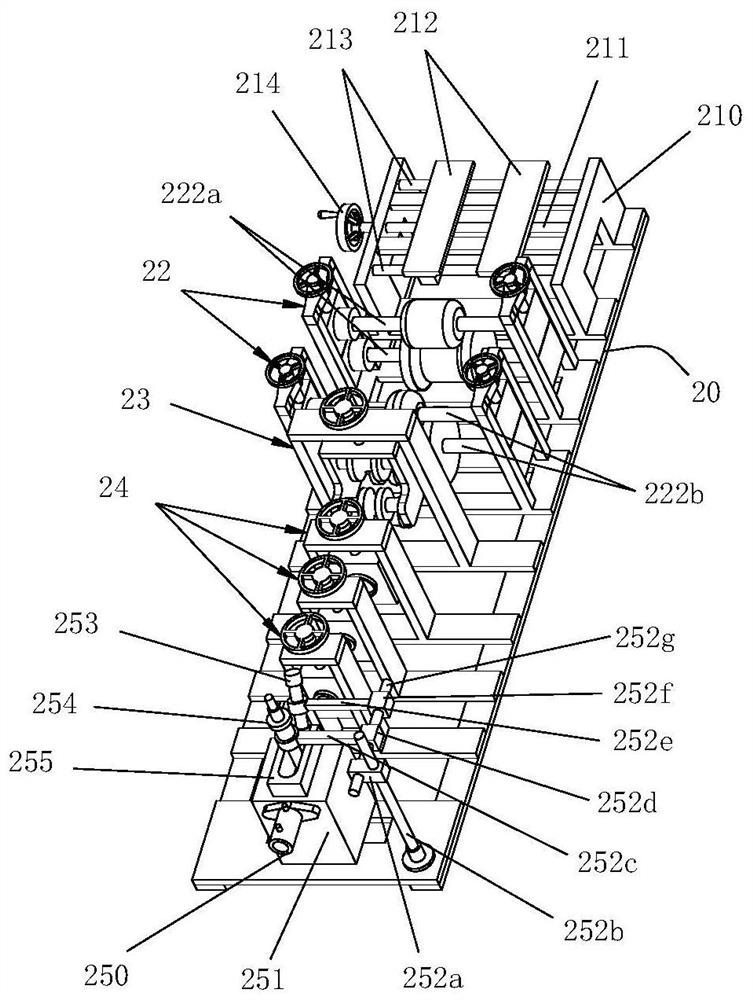

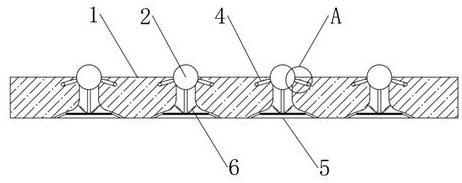

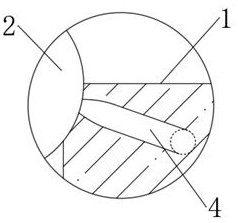

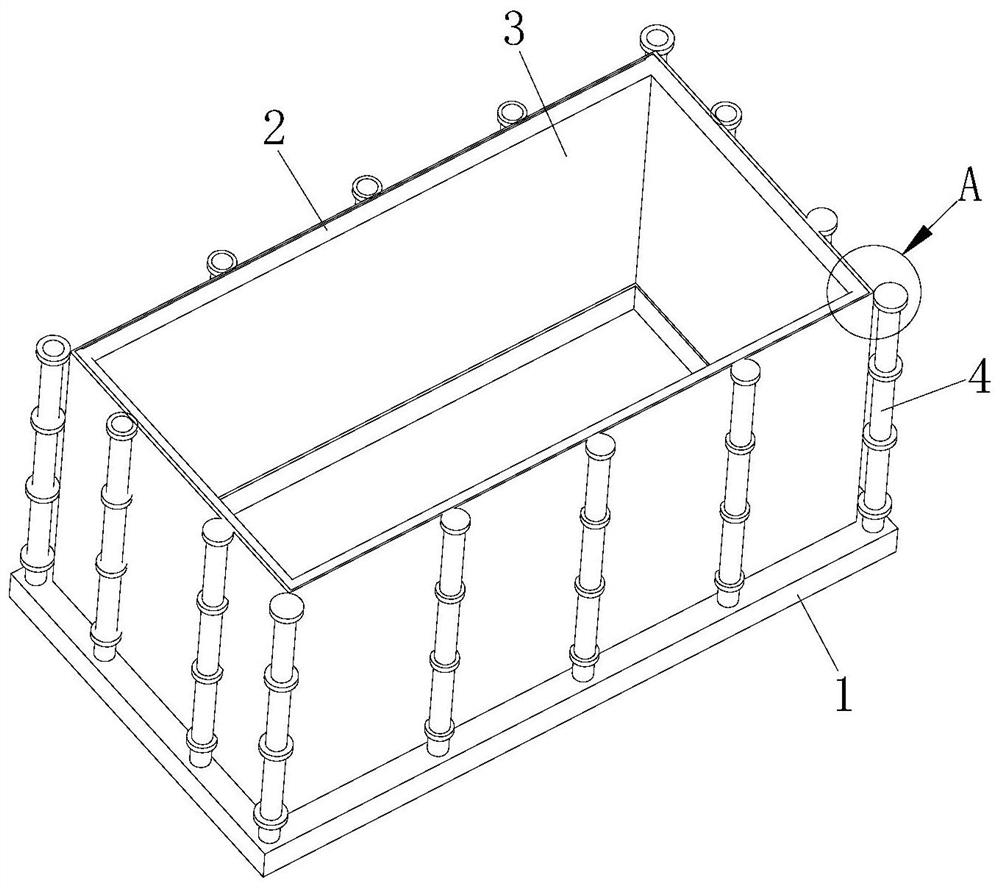

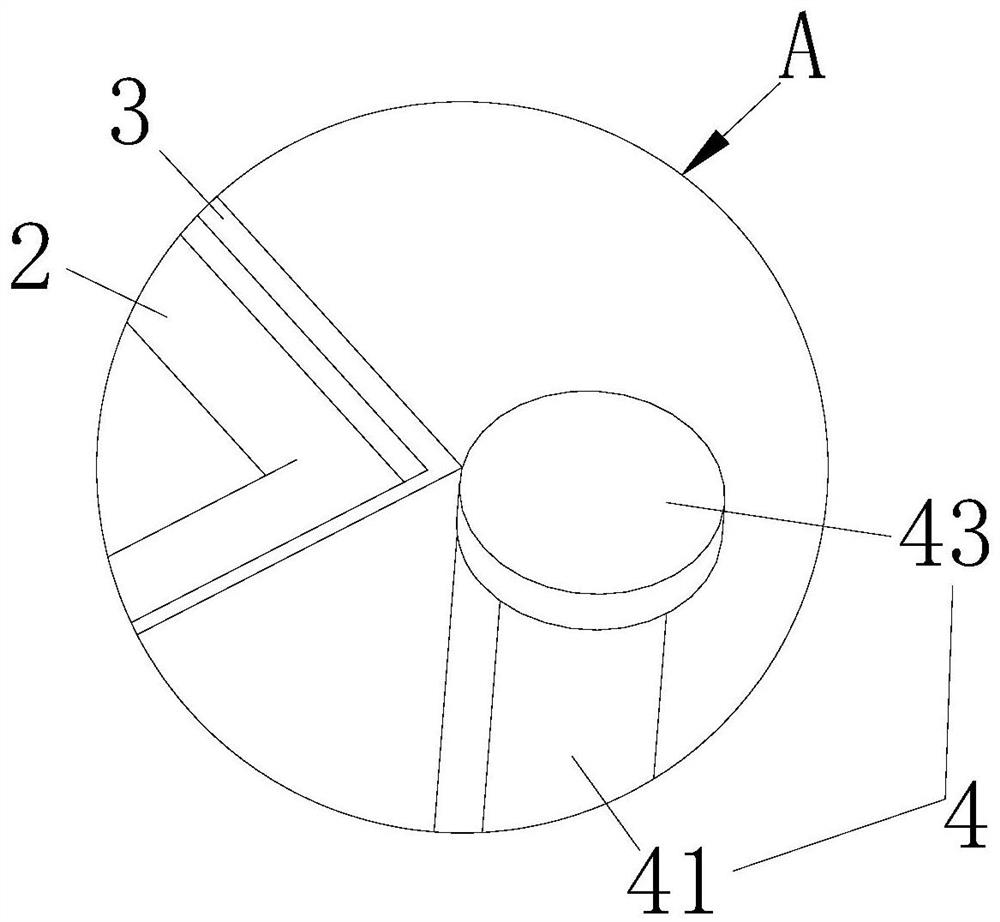

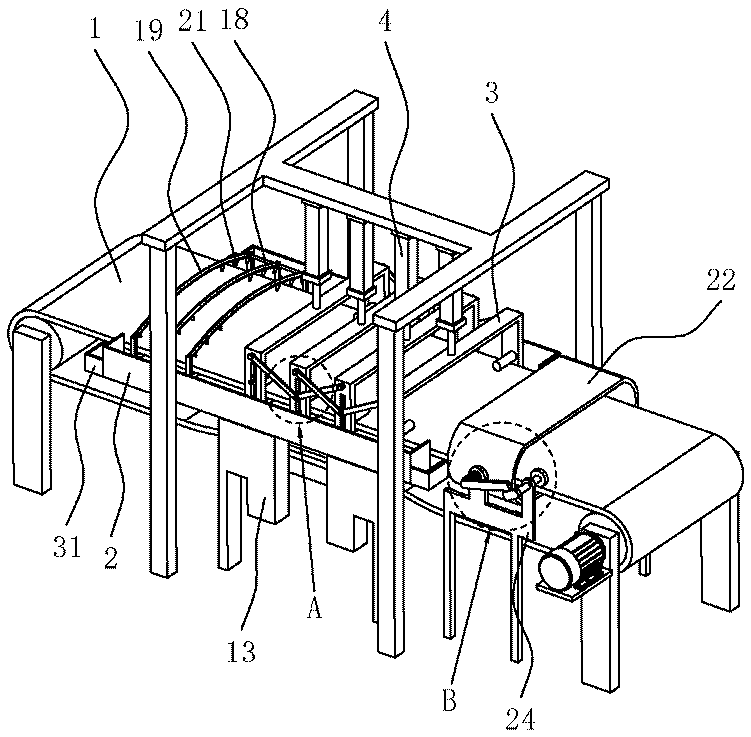

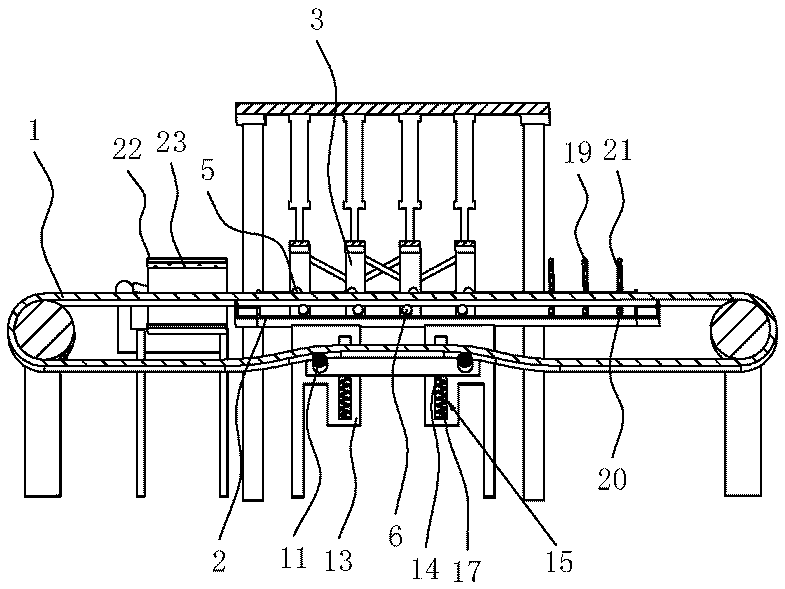

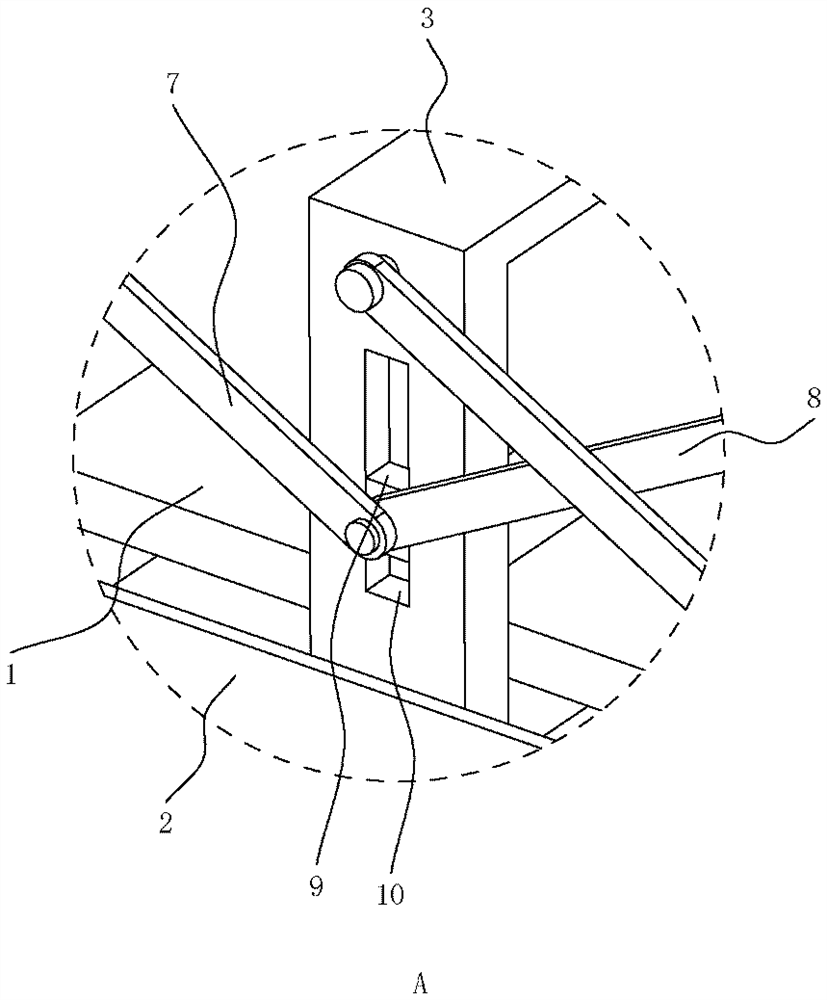

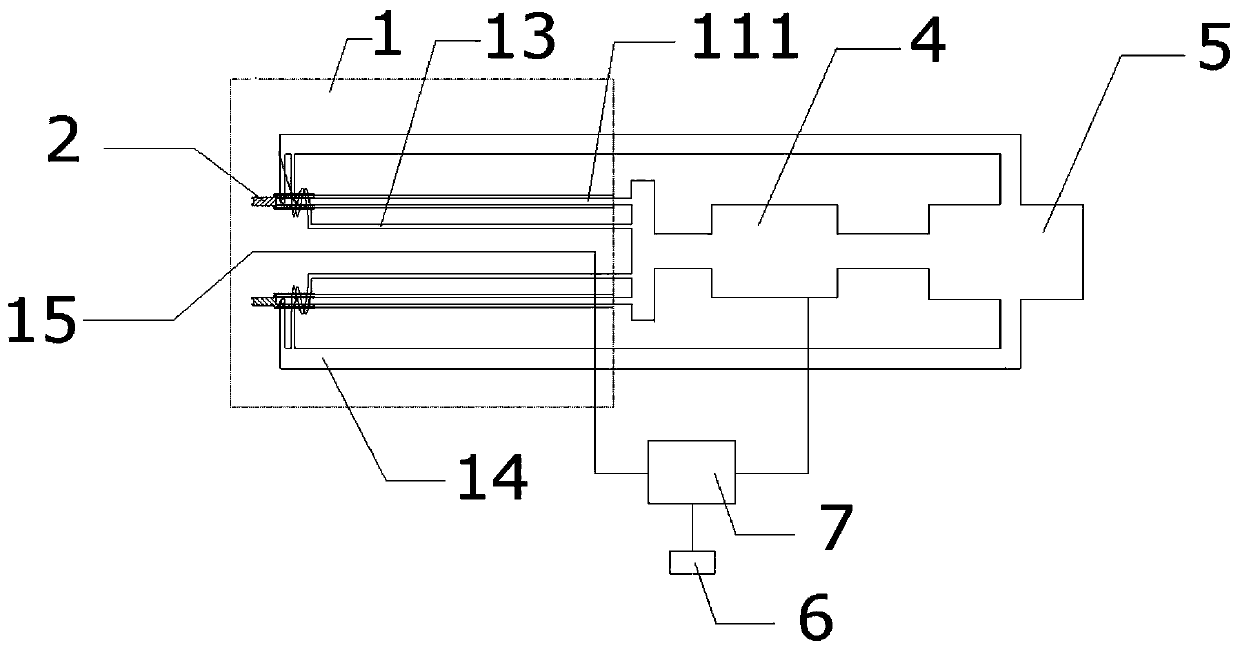

Production and processing system for polyethylene acrylic polyester polymer waterproof coiled material

The invention relates to a production and processing system for a polyethylene acrylic polyester polymer waterproof coiled material. The system comprises a mounting frame, a traction suite and a cooling suite, wherein the traction suite is mounted on the mounting frame, and the cooling suite is mounted on the inner side of the traction suite. The invention can solve the following problems during the production of the existing polyethylene acrylic polyester polymer waterproof coiled material: a, after being produced, the existing polyethylene acrylic polyester polymer waterproof coiled material is often cooled by cold water, so that the cooling efficiency is low, and the production efficiency is slowed down; b, after the existing polyethylene acrylic polyester polymer waterproof coiled material is cooled by cold water, a large amount of cooling water is often adhered to the surface, so that water stains on the surface of the polyethylene acrylic polyester polymer waterproof coiled material need to be manually removed, the workload of workers is greatly increased, and the polyethylene acrylic polyester polymer waterproof coiled material is prone to damage.

Owner:李正

A cooling device and method for electronic components based on the Knudsen effect

ActiveCN105431017BEfficient use ofEfficient secondary coolingModifications using liquid coolingSystems designCooling effect

The invention discloses a Knudsen effect-based electronic component cooling device and method. The device comprises a plurality of heat sinks, a plurality of metal components respectively corresponding to the heat sinks one by one, a plurality of Knudsen compressors, a condenser, a capillary throttling pipe and a plurality of evaporators, wherein each Knudsen compressor comprises a cooling cavity, a hot cavity and a micro-channel, and each evaporator corresponds to a heating part of an electronic component. A Knudsen effect-based cooling system design is integrated on a cooling device for heating electronic components to replace the conventional heat dissipation and cooling device, and refrigeration can be realized by directly utilizing heat released by the electronic components to realize secondary cooling, so that the cooling efficiency and the cooling effect are improved, and the device and the method have a higher application value in the field of electronic component cooling.

Owner:GUANGXI UNIV

A kind of hot spot floating ethernet switch

ActiveCN114679637BImprove cooling efficiencyImprove exchange efficiencyCooling/ventilation/heating modificationsSelection arrangementsThermodynamicsEngineering

The invention discloses an overheating point floating Ethernet switch, which belongs to the technical field of switches. The invention can use the deformation action of a heat shrink rod to pull the cooling cover to expand when the overheating phenomenon occurs during the working process of the switch body. The cooling water in the ball can enter the cooling cover through the water standpipe, and the cooling cover will also push the floating ball to float through the water standpipe during the expansion process. On the one hand, it can provide a visual overheat warning prompt. On the other hand, after the floating ball is moved out of the hemispherical floating hole, the air exchange efficiency between the outside world and the switch body can be improved, and the cooling water enters the cooling cover and absorbs heat to achieve temporary cooling. It shrinks, and the cooling water that absorbs heat is pressed back into the floating ball to facilitate heat dissipation to the outside world, and it is convenient to continue to absorb heat next time, which can effectively improve the heat dissipation efficiency of the switch body.

Owner:南通睿格特智能科技有限公司

Floating type cooling tower anti-overflow device and water collecting tray with same

PendingCN113028886AKeep dryImprove the protective effectTrickle coolersStructural engineeringMechanical engineering

The invention discloses a floating type cooling tower anti-overflow device. A light floating frame capable of floating on the water surface when meeting water is arranged above a fence base. When the water surface is flush with the bottom face of the floating frame, the bottom face of the floating frame is in contact with the water surface. The fence base is connected with the vertically corresponding pairwise frame edges of the floating frame through a telescopic waterproof cloth which surrounds the center of the floating frame by a circle. Cloth strip stretching assemblies for bearing the inward water pressure of the inner side of the telescopic waterproof cloth are arranged at the four corners outside the telescopic waterproof cloth. The top end of the telescopic waterproof cloth adheres to the movable end of the cloth strip stretching assembly. The top end of the telescopic waterproof cloth moves in the height direction of the cloth strip stretching assembly. According to the floating type cooling tower anti-overflow device, overflowing water is prevented from corroding a bearing platform, the dryness of the bearing platform can be kept, and the protection effect on the bearing platform is improved. The overflow phenomenon caused by the out-of-level bearing platform is weakened. The structure is simple, and anti-overflow operation is easy and reliable.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Target material mounting structure, magnetron sputtering equipment and magnetron sputtering method

ActiveCN112899627ASmall sizeIncrease cooling areaVacuum evaporation coatingSputtering coatingSputteringWater pipe

The invention discloses a target material mounting structure, magnetron sputtering equipment and a magnetron sputtering method, and solves the technical problems of poor heat dissipation and short service life of an existing target material. The target material mounting structure comprises a target material and a back plate, wherein the target material is installed at one side of the back plate. The target material mounting structure is characterized in that a heat dissipation assembly is arranged in the back plate and comprises a cooling water pipe and an injection and suction assembly, the cooling water pipe is close to the side of the target material, the injection and suction assembly is located away from the target material, and the cooling water pipe is connected with the injection and suction assembly. The target material mounting structure has the advantages that the heat dissipation effect is good, the service life of the target material is long, and cooling water is not prone to falling into a vacuum cavity.

Owner:CHONGQING COLLEGE OF ELECTRONICS ENG

Cooling device for aluminum alloy casting processing equipment

ActiveCN112045155BRealize continuous castingRealize automatic unloadingWater storage tankEngineering

The invention belongs to the field of casting, especially a cooling device for aluminum alloy casting processing equipment. The following proposal is proposed, which includes a water storage tank and a fixing plate. The middle position of the plate is rotatably connected with a rotating column, and the bottom end of the rotating column is fixedly connected with a transmission disc located below the fixed plate. There are four transmission holes arranged in a circular array on the edge of the transmission disc. The top of the water storage tank is installed with a An electric motor, the output shaft of the motor is connected with a swing piece, the top side of the swing piece is fixedly connected with a sliding block slidingly connected with the transmission hole, the top end of the rotating column is fixedly connected with a mounting plate, and four rings are fixedly connected on the mounting plate The casting mold arranged in an array is provided with a plurality of casting wells arranged in an annular array on the casting mold, and the casting wells pass through the mounting plate. The invention can realize the continuous casting of the aluminum alloy rod, and realize the secondary cooling in the casting process, the cooling speed is fast, and the processing efficiency is high.

Owner:东莞安兴五金压铸有限公司

Combustion system and burner

ActiveCN110577846BAvoid softening and deformationSolve the burning problemCombustible gas productionCombustion systemThermodynamics

The invention belongs to the field of coal gasification combustion, and relates to a combustion system and a burner. The combustion system includes a control system, a burner and a gasifier connected in sequence, the burner includes a cooling water jacket and an outer casing, the cooling water jacket is an annular cavity structure and is arranged inside the outer casing ; The first outer wall of the cooling water jacket forms the central channel of the burner, and the second outer wall of the cooling water jacket and the inner wall of the outer casing form a nitrogen channel. The invention can effectively avoid gasification by controlling the installation angle between the opposed burner with a special structure and the wall of the gasification furnace at 17°-20°, and controlling the swirl angle of the air outlet of the burner at 1°-30° Partial burning of the furnace, channeling and other problems.

Owner:杨建平

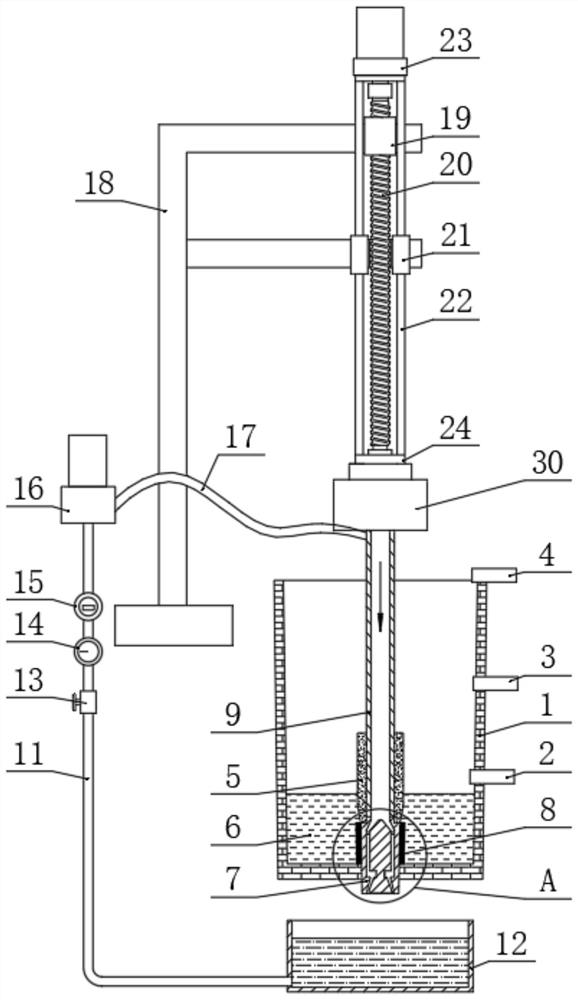

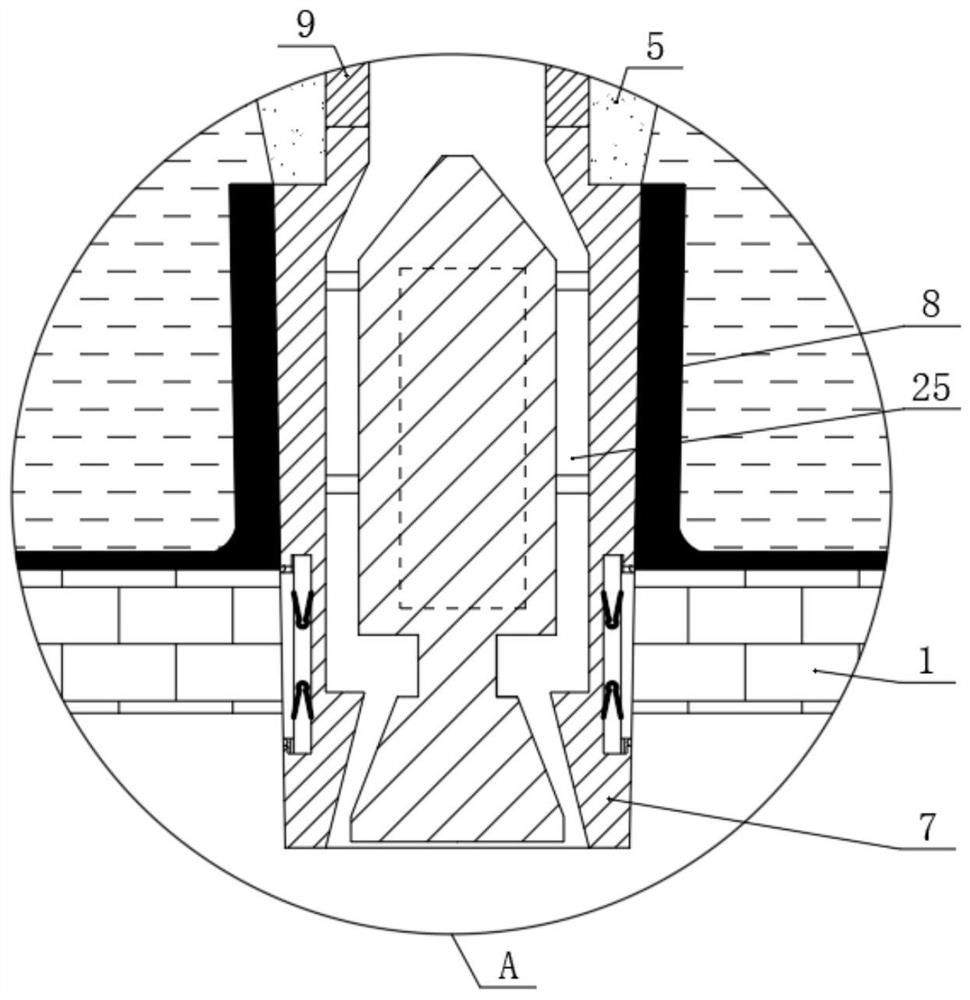

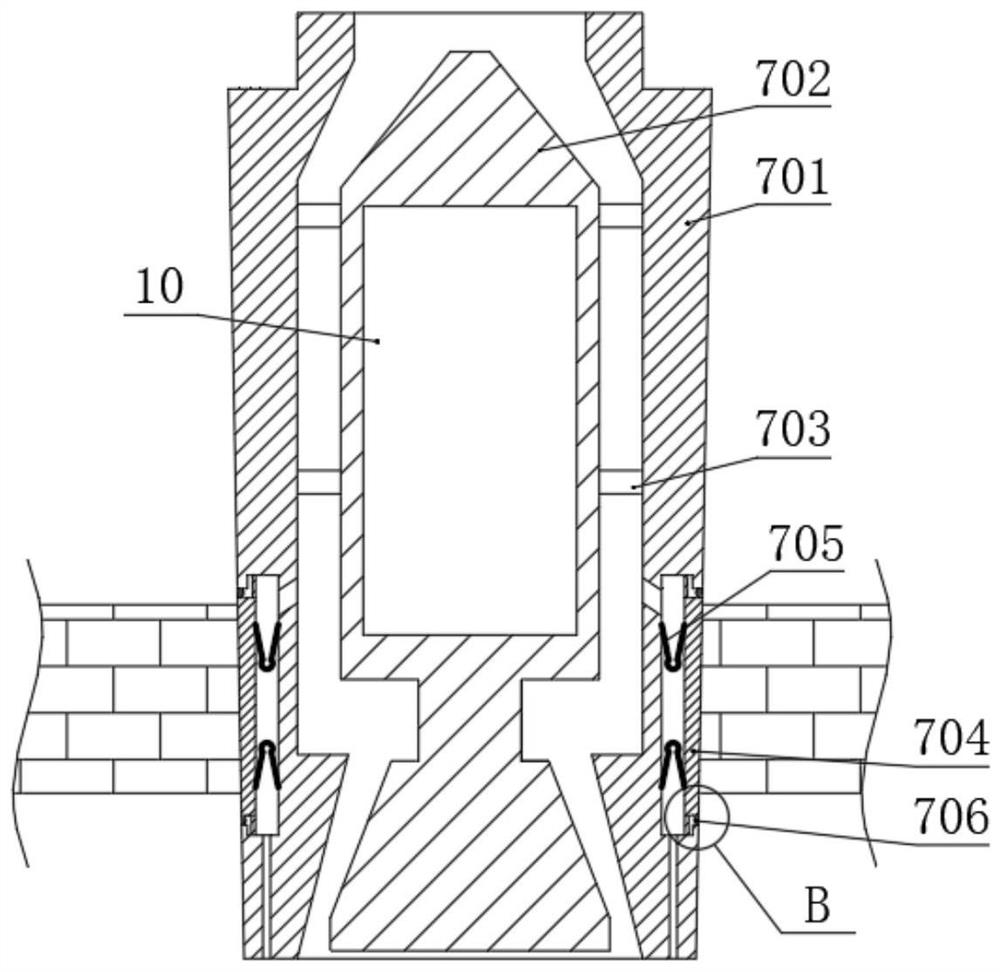

Hollow cast ingot inner hole casting device

ActiveCN113976842AReduce the amount of smeltingReduce wasteNuclear energy generationIngot casting plantsIngot castingMolding machine

The invention discloses a hollow cast ingot inner hole casting device which comprises an ingot mold. A cooling forming mechanism is inserted into the ingot mold, a lifting mechanism is arranged above the cooling forming mechanism, a connecting pipe is arranged at the top end of the cooling forming mechanism, and a connecting seat is arranged at the top end of the connecting pipe. The top of the connecting seat is fixedly connected with the driving end of the lifting mechanism, an oscillator is arranged in the cooling forming mechanism, and a cooling mechanism is in fluid communication with the liquid inlet end of the cooling forming mechanism. By arranging the ingot mold with the mounting hole in the bottom, cooperating with the crystallizer and cooperating with the lifting mechanism, a metal ingot with a hollow structure can be cast, casting defects are remarkably reduced, troubles caused by later secondary transferring and drilling are avoided, metal material waste caused by drilling is reduced, the metal smelting amount is effectively reduced, the purposes of energy conservation and emission reduction are achieved, production efficiency is improved, ingot casting quality is improved, and the problem that production cost is increased is solved.

Owner:内蒙古展华科技有限公司 +1

A zinc alloy forming and cooling integrated production device

ActiveCN112222397BAchieve secondary coolingEfficient cooling and forming effectCasting plantsDrive wheelChain conveyor

The application relates to an integrated production device for zinc alloy forming and cooling, which relates to the field of alloy forming devices, which includes a cooling system, which includes a water tank, and the middle part of the inner side of the water tank is provided with a plurality of edges for movable clamping of the two sides of the chain conveyor belt. The clamping assembly is equipped with a mounting plate above the water tank and the clamping assembly is installed on the mounting plate. The cooling system also includes a drive for driving the mounting plate up and down; the driving wheel of the chain conveyor belt is provided with a speed sensor. The speed sensor The console is electrically connected, and multiple driving parts are electrically connected to the console; when the speed sensor detects that the rotation speed of the driving wheel of the chain conveyor belt is higher than the set value, the console controls different numbers of driving parts to start and drive the mounting plate to move down , the greater the rotation speed of the driving wheel of the chain conveyor belt, the more the number of driving parts is controlled to start. The application has the effect of automatically monitoring the production rate of the zinc alloy and correspondingly improving the cooling forming quality.

Owner:佛山市桂源锌合金材料有限公司

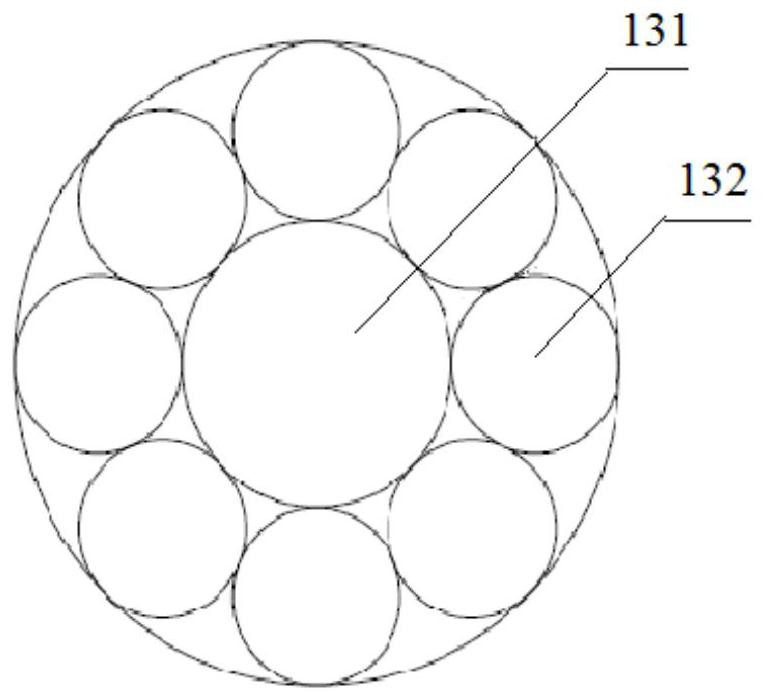

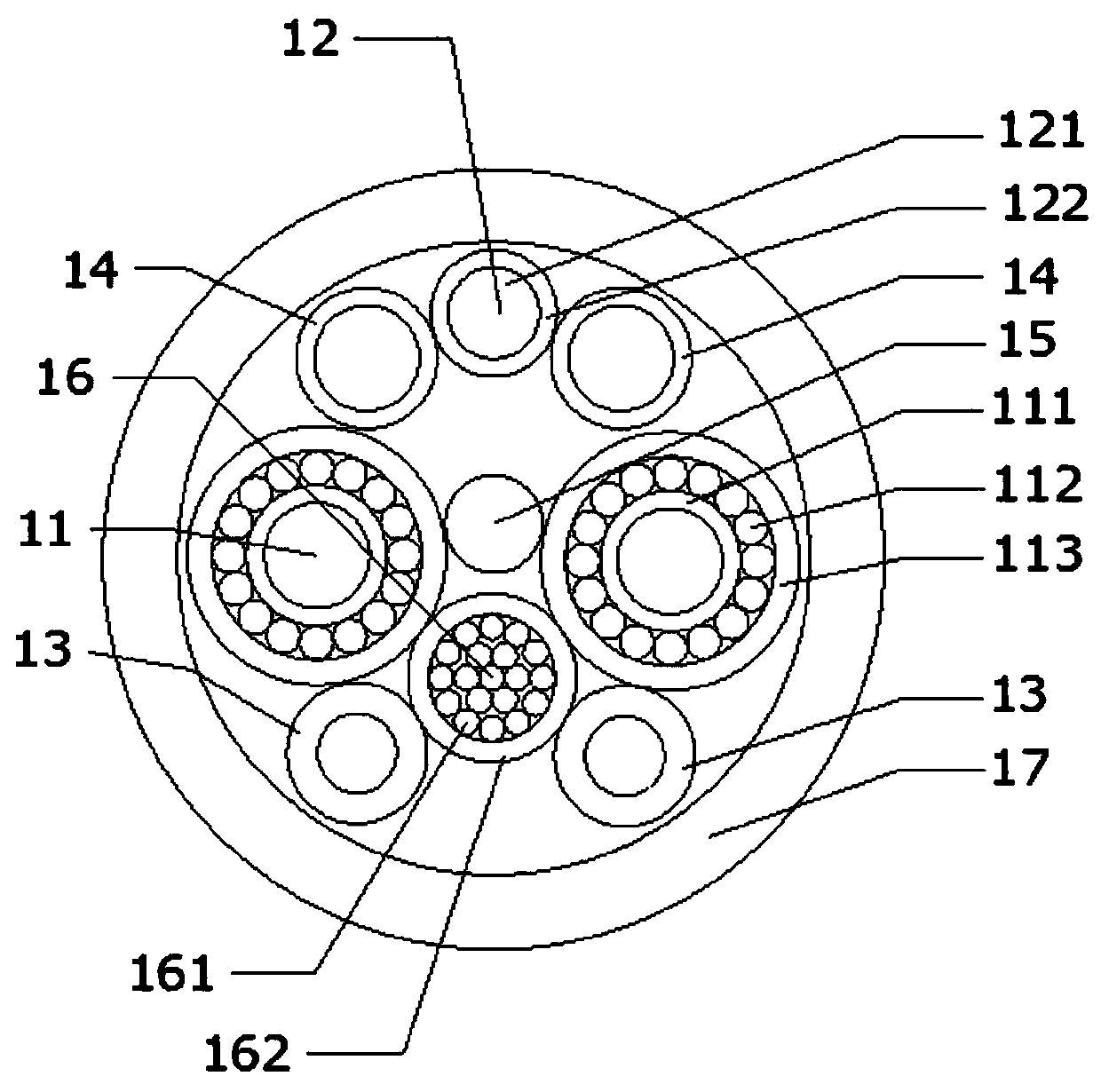

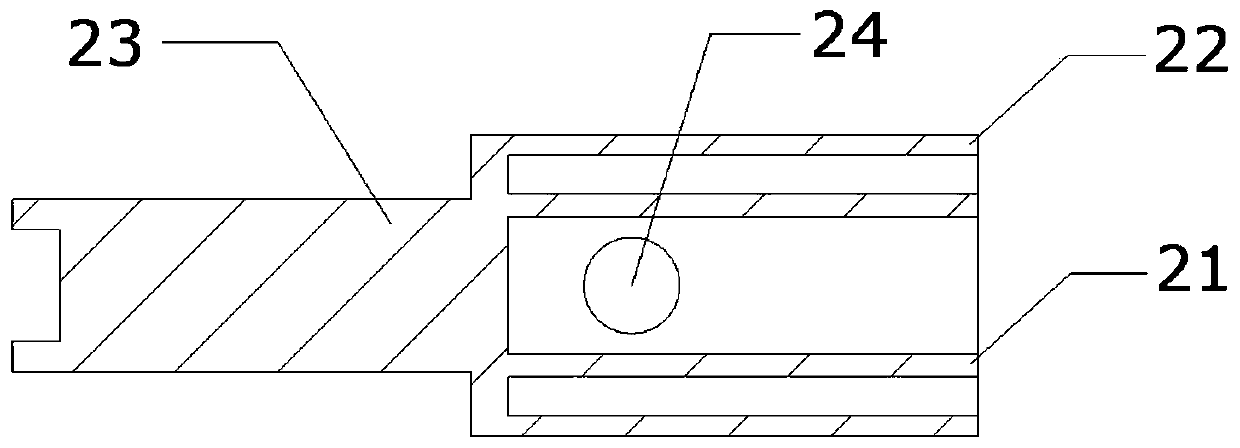

Electric vehicle high current charging cable

ActiveCN106782835BAchieve secondary coolingReduce CooldownInsulated cablesPower cablesElectrical resistance and conductanceEngineering

The invention discloses a high-current charging cable used for an electric vehicle. The high-current charging cable comprises at least one strand of wires, wherein the wires are arranged in the cable; the high-current charging cable also at least comprises a first inflow pipe used for conveying a cooling medium and at least one outflow pipe; each first inflow pipe is arranged in the corresponding wires in a penetration manner; the first inflow pipe is connected with one end of the corresponding outflow pipe at one ends of the corresponding wires in a conduction manner; and each outflow pipe is arranged close to the corresponding wires. The high-current charging cable has the beneficial effects as follows: the charging cable provided by the invention has a cooling pipeline, so that a good refrigerating effect is achieved; and a specially-manufactured hole-sleeve-structured adapter is adopted, so that the first inflow pipe is protected while the contact area between the adapter and the wires is enlarged, thereby greatly lowering the contact resistance of the adapter.

Owner:深圳宝新电线电缆制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com