Fireproof cable conveying equipment with annealing function

A technology for fireproof cables and transmission equipment, applied in heat treatment equipment, improving energy efficiency, improving process efficiency, etc., can solve the problems of low cable annealing efficiency, improve heating efficiency and energy utilization, avoid heat loss, increase The effect of high flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

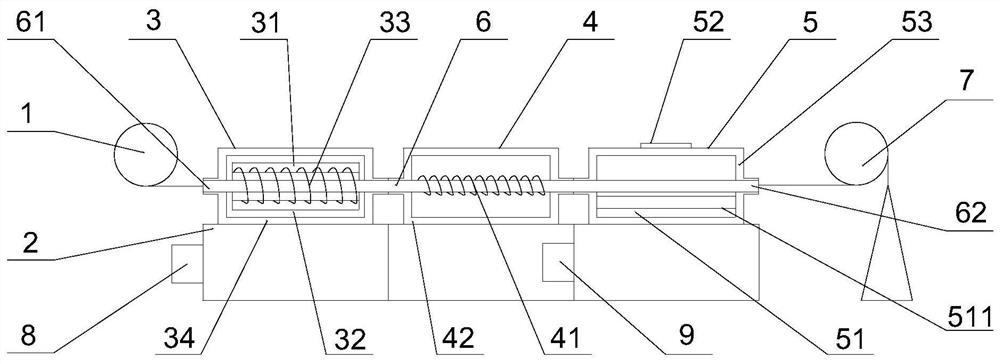

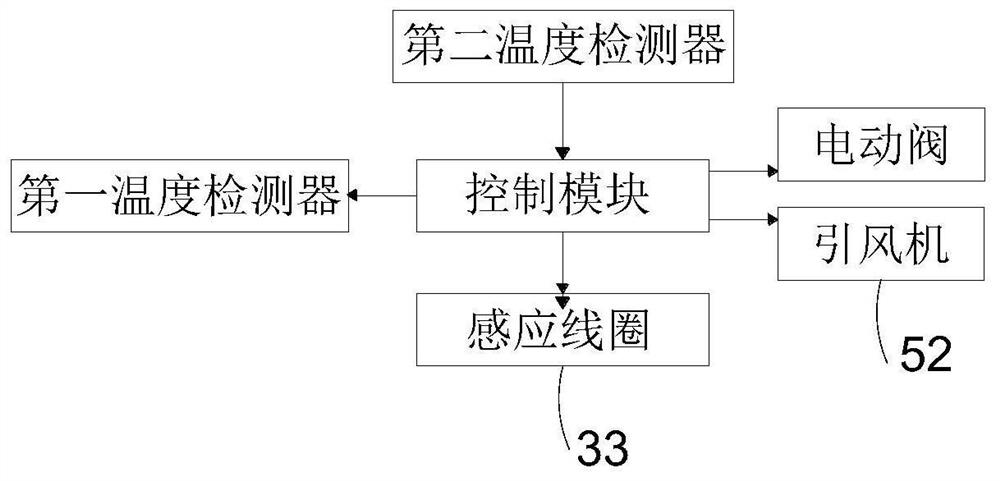

[0017] refer to figure 1 and figure 2 , the fireproof cable transmission equipment with annealing function provided in this embodiment is used to realize the transmission and annealing function of a fireproof cable. The cable is treated by annealing process so that the inner copper wire can reach the conductor performance required by the cable product, so as to eliminate internal stress and defects, and restore it to the physical and mechanical properties before stretching. The fireproof cable with annealing function The transmission device includes an annealing module, a transmission module, a detection module and a control module.

[0018] refer to figure 1 , the annealing module includes a base support 2 and a fireproof cable transmission channel 6 arranged on the base support 2, and an induction heating box 3 is sequentially arranged in the fireproof cable transmission channel along the transmission direction of the fireproof cable , a first cooling box 4 and a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com