Electric vehicle high current charging cable

A technology for charging cables and electric vehicles, which is applied in the direction of power cables, insulated cables, cables, etc., which can solve the problems of unguaranteed service life of cables, increase of charging current, heating of cables, etc., to facilitate automatic operation, save cooling costs, The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

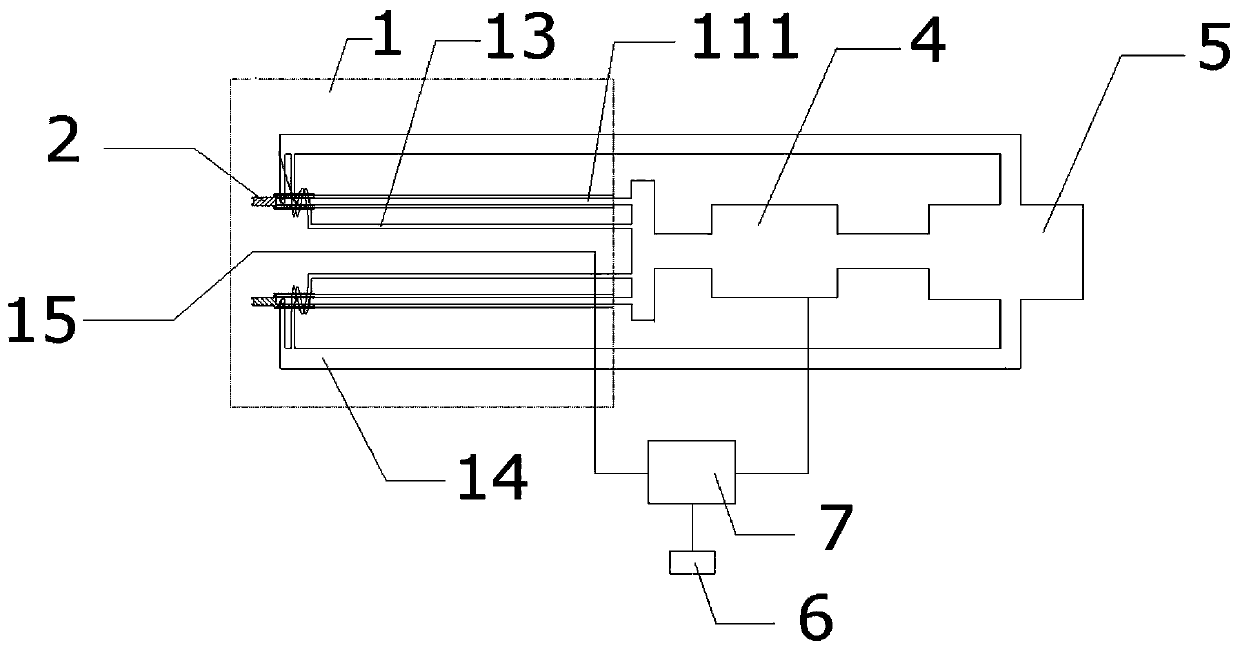

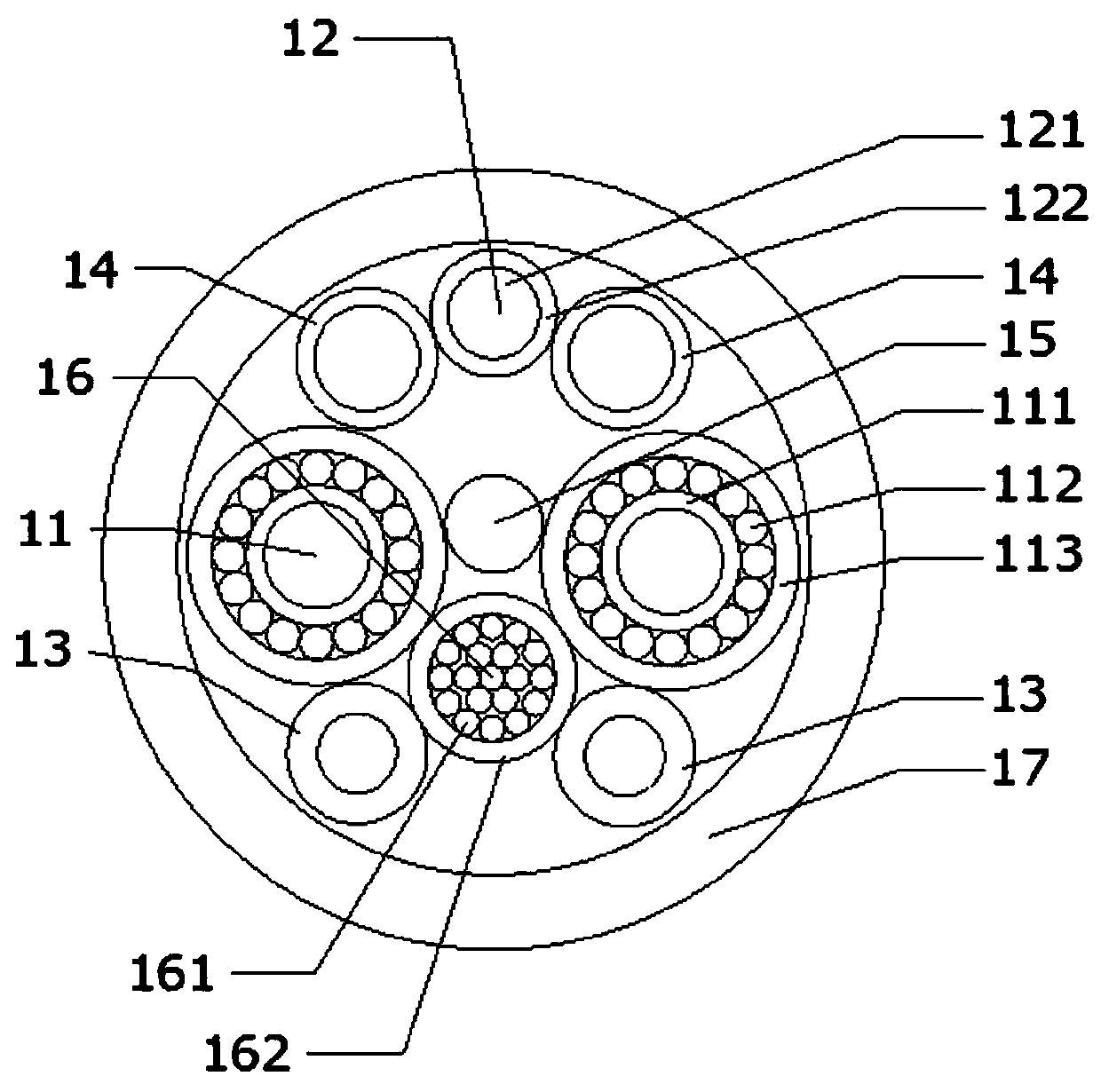

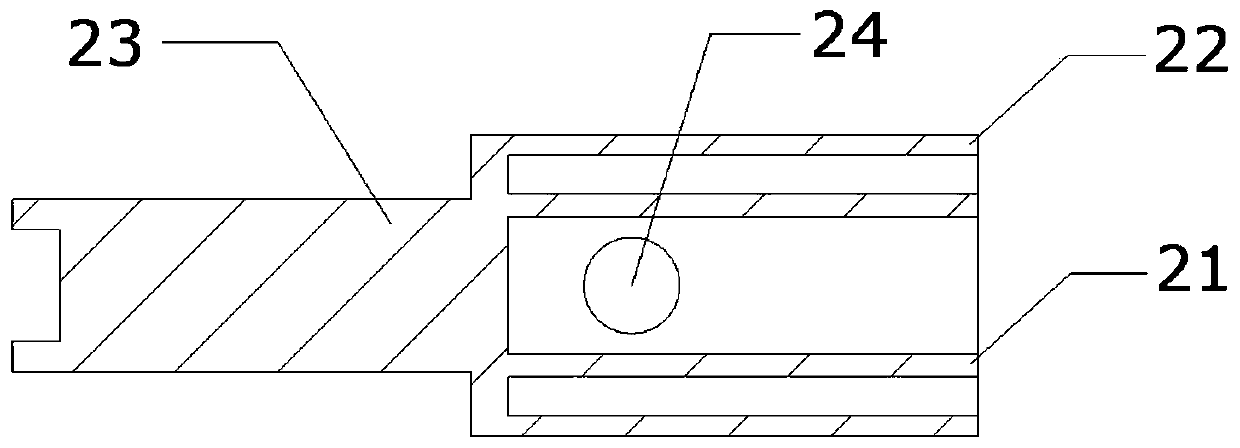

[0025] refer to Figure 1-3 , a high-current charging cable for electric vehicles, including at least one wire 112, the wire 112 is arranged in the cable 1, and at least includes a first inflow pipe 111 and an outflow pipe 14 for transmitting a cooling medium; the first inflow pipe 111 passes through the inside of the wire 112 , the first inflow pipe 111 is conductively connected to one end of the outflow pipe 14 at one end of the wire 112 , and the outflow pipe 14 is arranged adjacent to the wire 112 .

[0026] The high-current charging cable provided by the present invention has its own inflow cooling pipe and outflow cooling pipe. Compared with only one inflow cooling pipe, when the same amount of cooling medium is passed through, the present invention can realize secondary cooling, which greatly reduces the coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com