Target material mounting structure, magnetron sputtering equipment and magnetron sputtering method

An installation structure and magnetron sputtering technology, applied in sputtering coating, metal material coating process, vacuum evaporation coating, etc., can solve the problems of poor heat dissipation and short target life, and achieve rapid cooling, Strong power, guarantee the effect of equipment safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

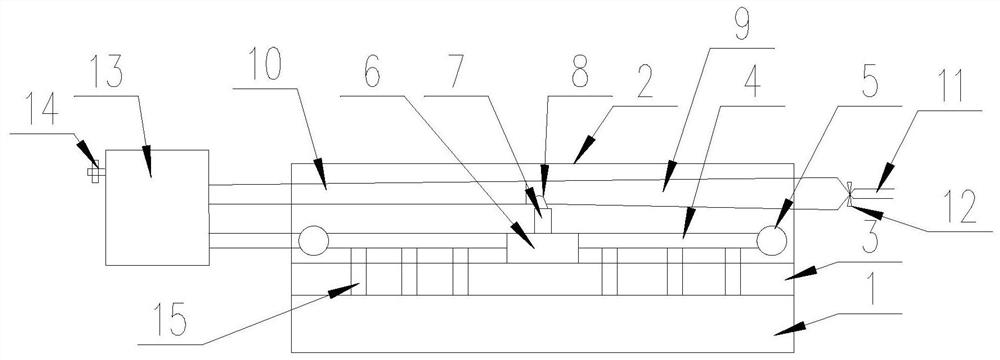

[0043] Such as figure 1 with figure 2 As shown, a target 1 installation structure includes a target 1 and a back plate 2, the target 1 is installed on one side of the back plate 2, and the feature is that a heat dissipation component is arranged inside the back plate 2, so The heat dissipation assembly includes a cooling water pipe and a suction assembly, the cooling water pipe is close to the target 1 side, the injection suction assembly is located away from the target 1, and the cooling water pipe is connected to the injection suction assembly.

[0044] The injection suction assembly includes an air pressure pipe 11, a ventilation pipe 9 and a drain pipe 10 connected in sequence, the ventilation pipe 9 communicates with one end of the injection suction pipe 8, and the other end of the injection suction pipe 8 is connected with the water suction pipe 7, so that The cooling water pipe is connected to the water suction pipe 7 , the drain pipe 10 is connected to a closed water...

Embodiment 2

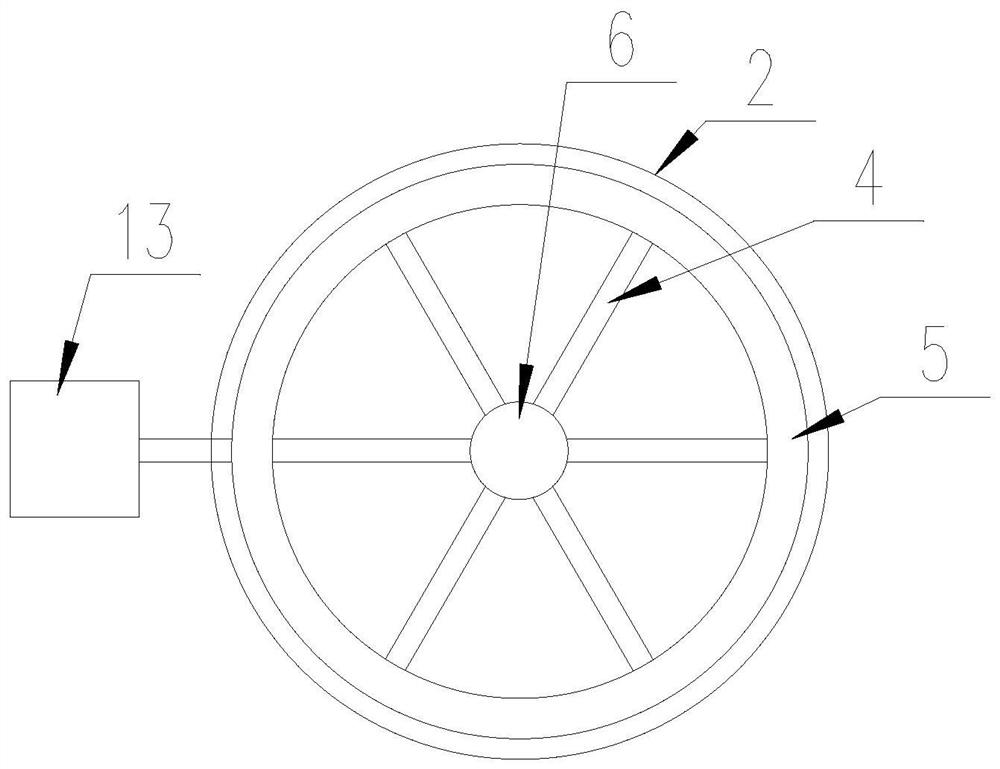

[0051] The difference between this embodiment and Embodiment 1 is that the back plate 2 is circular, and the cooling water pipe also includes a ring pipe 5, and the ring pipe 5 is annularly distributed inside the back plate 2, and the water collecting tank 6 is located in the ring shape of the ring pipe 5 , one end of the plurality of branch pipes 4 is connected to the ring pipe 5 , and the other end of the plurality of branch pipes 4 is connected to the water collecting tank 6 .

[0052] The branch pipes 4 are radially distributed inside the back plate 2 , and the water collecting tank 6 is arranged concentrically with the annular pipe 5 .

[0053] The annular pipe 5 is connected to a closed water tank 13, and a pressure relief valve 14 is arranged on the closed water tank 13.

[0054] The present invention connects the cooling water pipe and the drain pipe 10 of the injection suction assembly to the water tank, which can realize the recycling of cooling water. Since the high...

Embodiment 3

[0057] The difference between this embodiment and Embodiment 2 is that a pressure sensor is set on the airtight water tank 13, the pressure relief valve 14 is a solenoid valve, and the pressure sensor is used to detect the pressure in the airtight water tank 13 and transmit data For the PLC controller, the PLC controller controls the opening of the electromagnetic valve according to the data, so as to ensure that the pressure of the airtight water tank 13 does not exceed the threshold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com