Zinc alloy forming and cooling integrated production device

A production device, zinc alloy technology, applied in metal processing equipment, manufacturing tools, foundry workshops, etc., can solve the problem of difficult to control the quality of zinc alloy products, achieve high-efficiency air-drying effect, ensure stable transmission, stable cooling and forming effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

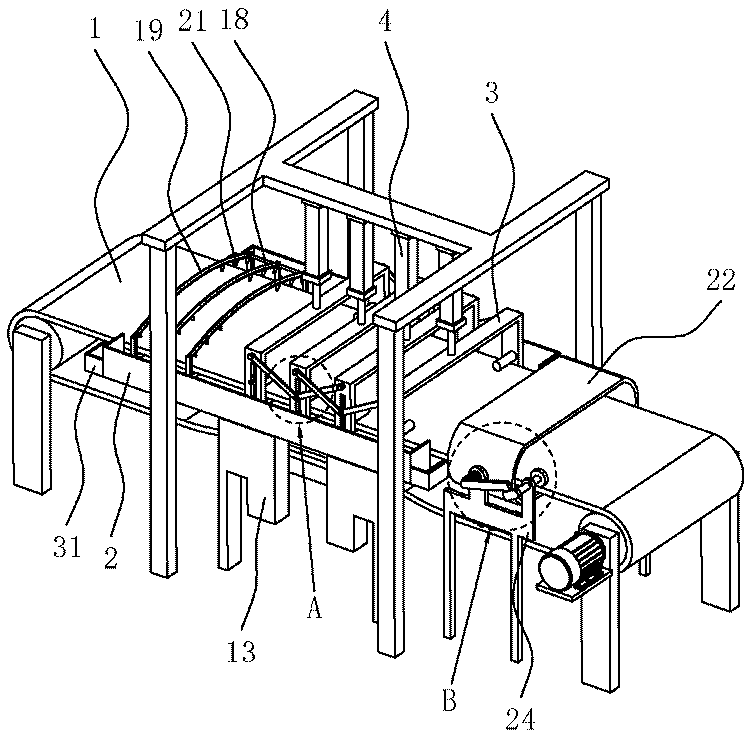

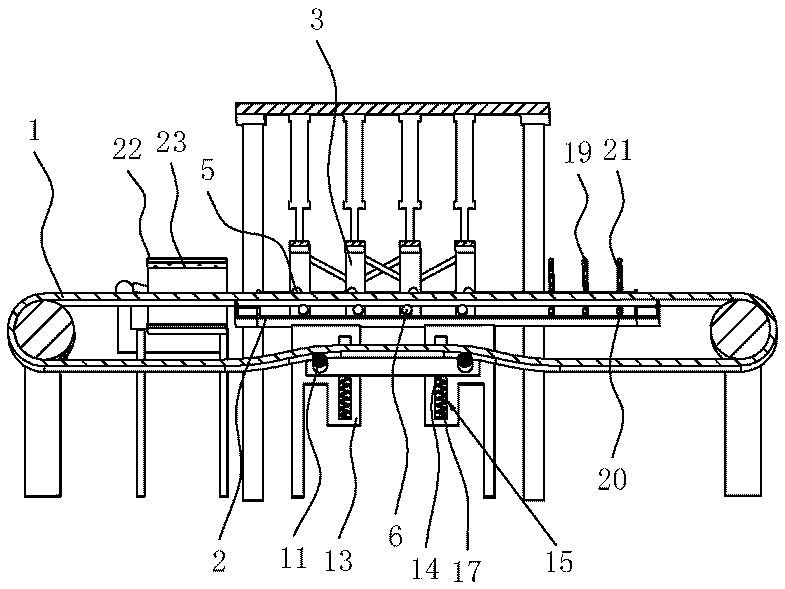

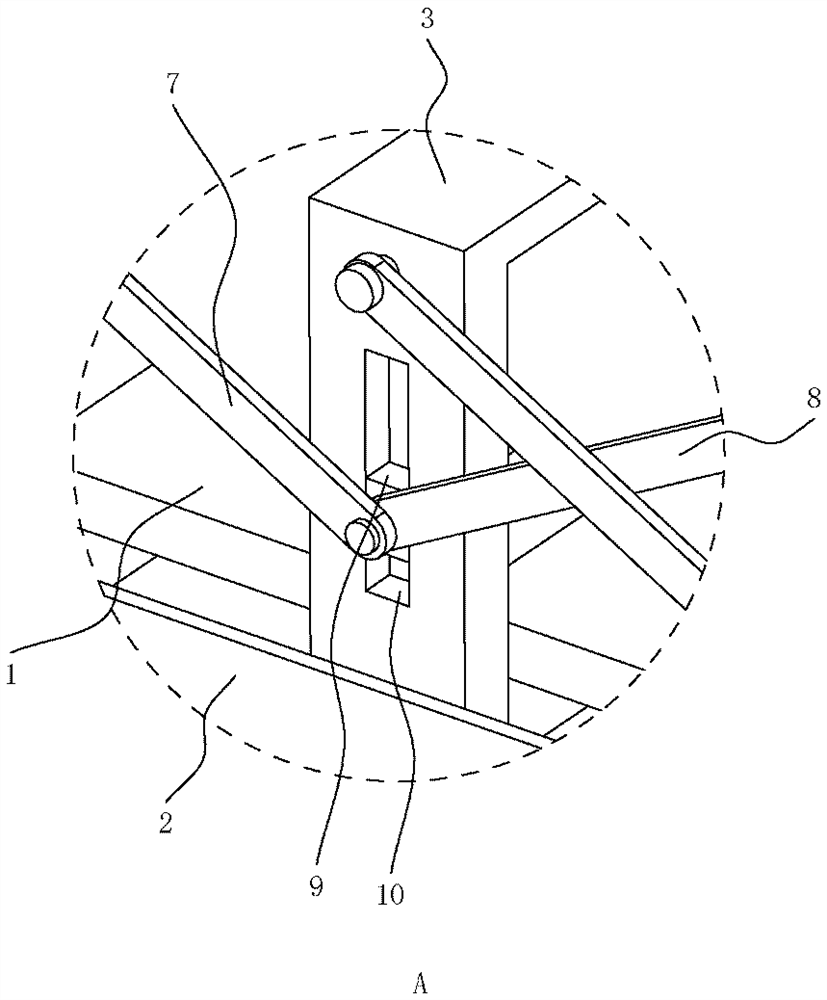

[0038] The following is attached Figure 1-4 The application is described in further detail.

[0039] The embodiment of the present application discloses an integrated zinc alloy forming and cooling production device. refer to figure 1 , the zinc alloy forming and cooling integrated production device includes a linear ingot casting machine, an automatic casting device, a cooling system, an automatic demoulding device, an alignment machine, an automatic palletizing device, a chain conveyor belt 1 for connecting various parts, and a The frame 24 of the chain conveyor belt 1, the frame 24 is strip-shaped and arranged along the conveying direction of the chain conveyor belt 1, and the chain conveyor belt 1 is a mesh belt type chain conveyor belt 1 common in the art; the cooling system includes The water tank 2 that is installed on the frame 24 and is arranged along the length direction of the frame 24, the two ends of the length direction of the water tank 2 are all provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com