Extrusion-screw puffing cavity structure

A technology of extruding screw and puffing cavity, applied in food science and other directions, can solve the problems of unfavorable product shaping and high in vitro digestion rate, and achieve the effect of improving quality, promoting starch molecular rearrangement and improving nutritional quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

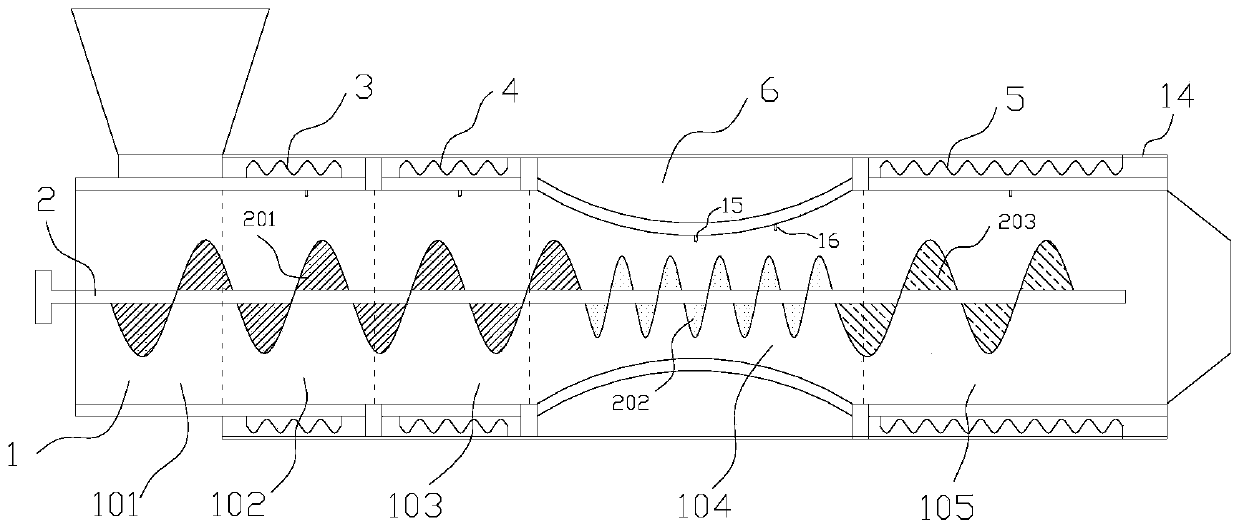

[0030] A kind of extrusion screw puffing cavity structure, please refer to figure 1 , including an expansion chamber 1 and a screw 2 housed in the cavity 1, wherein the expansion chamber 1 includes a feed conveying chamber 101 distributed sequentially from the feed end to the discharge end, the first section of high-temperature heating chamber 102, the second section The high-temperature heating chamber 103, the low-temperature heating chamber 104, the third high-temperature heating chamber 105, the first high-temperature heating chamber 102, the second high-temperature heating chamber 103, and the third high-temperature heating chamber 105 are respectively provided with first A high-temperature heating resistance wire 3, a second high-temperature heating resistance wire 4, and a third high-temperature heating resistance wire 5. A refrigerant chamber 6 is arranged outside the wall of the low-temperature heating chamber 104, and the wall of the low-temperature heating chamber 10...

Embodiment 2

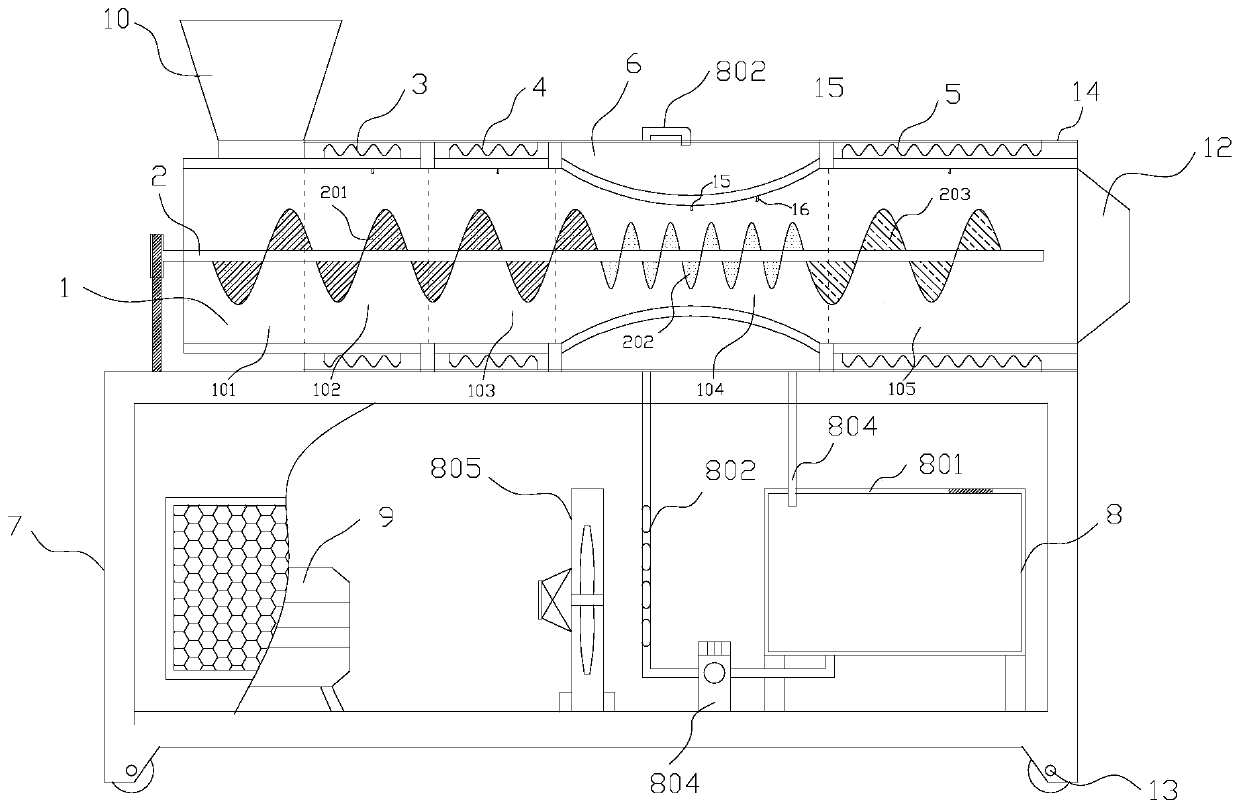

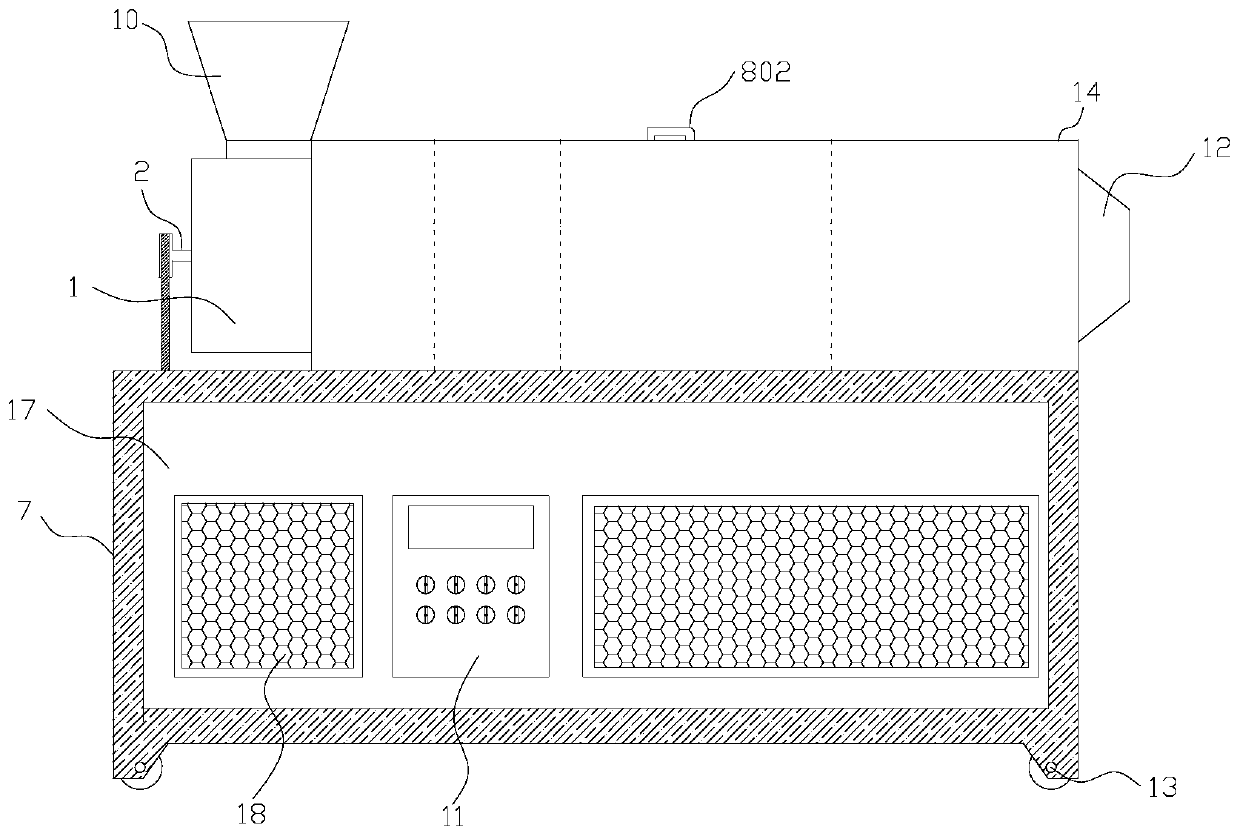

[0035] A kind of extruding screw expansion equipment, please refer to figure 2 , image 3 , Figure 4 , including an expansion chamber 1, a screw 2 accommodated in the expansion chamber 1, a frame 7, a molding channel 12 arranged at the discharge end of the expansion chamber 1, a motor 9 for driving the screw 2 to rotate, and an inlet arranged at the input end of the expansion chamber 1 Hopper 10, control cabinet 11, cooling system 8;

[0036] Among them, the cooling system 8 includes a refrigerant circulation box 801, a refrigerant inlet pipe 802 that communicates with the bottom of the refrigerant circulation box 801 at one end and communicates with the top of the refrigerant chamber 6 at one end. The refrigerant outlet pipe 803 connected to the bottom of the chamber 6, and the refrigerant circulation pump 804 arranged on the refrigerant inlet pipe 802;

[0037] The puffing chamber 1 includes a feed conveying chamber 101, a first-stage high-temperature heating chamber 10...

Embodiment 3

[0045] A processing method for starch-rich puffed food, using the extrusion screw puffing equipment in Example 2, feeding materials from the feed port 10, respectively controlling the first high-temperature heating chamber 102 and the second high-temperature heating chamber 103. The temperature of the low-temperature heating chamber 104 and the third-stage high-temperature heating chamber 105 is 70-90°C, 90-120°C, 40-65°C, and 90-120°C; the pressure of the low-temperature heating chamber 104 is controlled to be 10-20MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com