Production and processing system for polyethylene acrylic polyester polymer waterproof coiled material

A polyethylene polypropylene polyester, polymer waterproof technology, applied to flat products, household appliances, other household appliances, etc., can solve the problems of slow cooling efficiency, large friction coefficient, and small linear expansion coefficient, so as to improve cooling efficiency and increase Work load, accelerated heat dissipation and cooling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

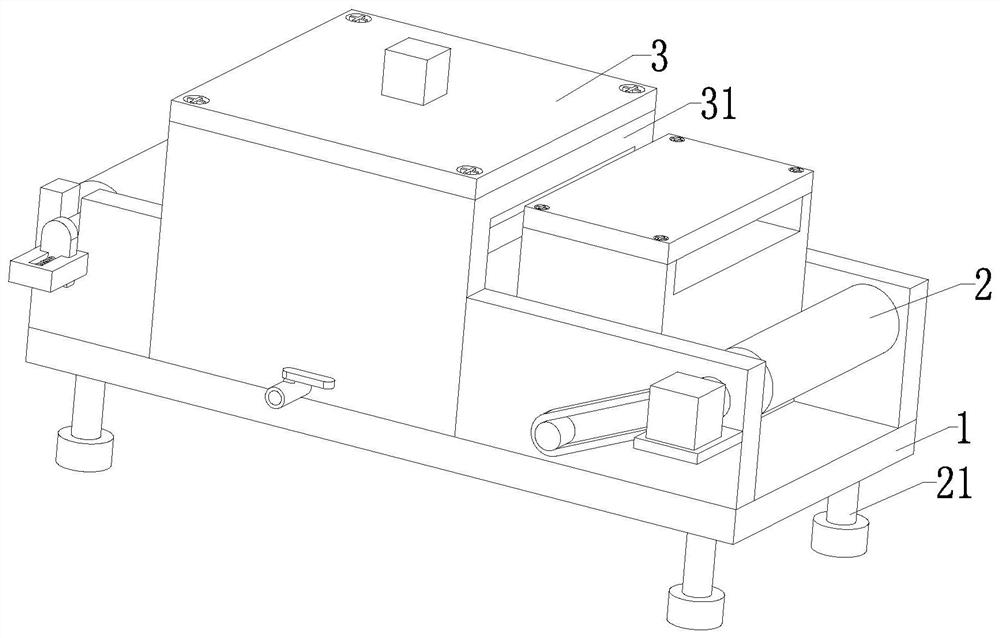

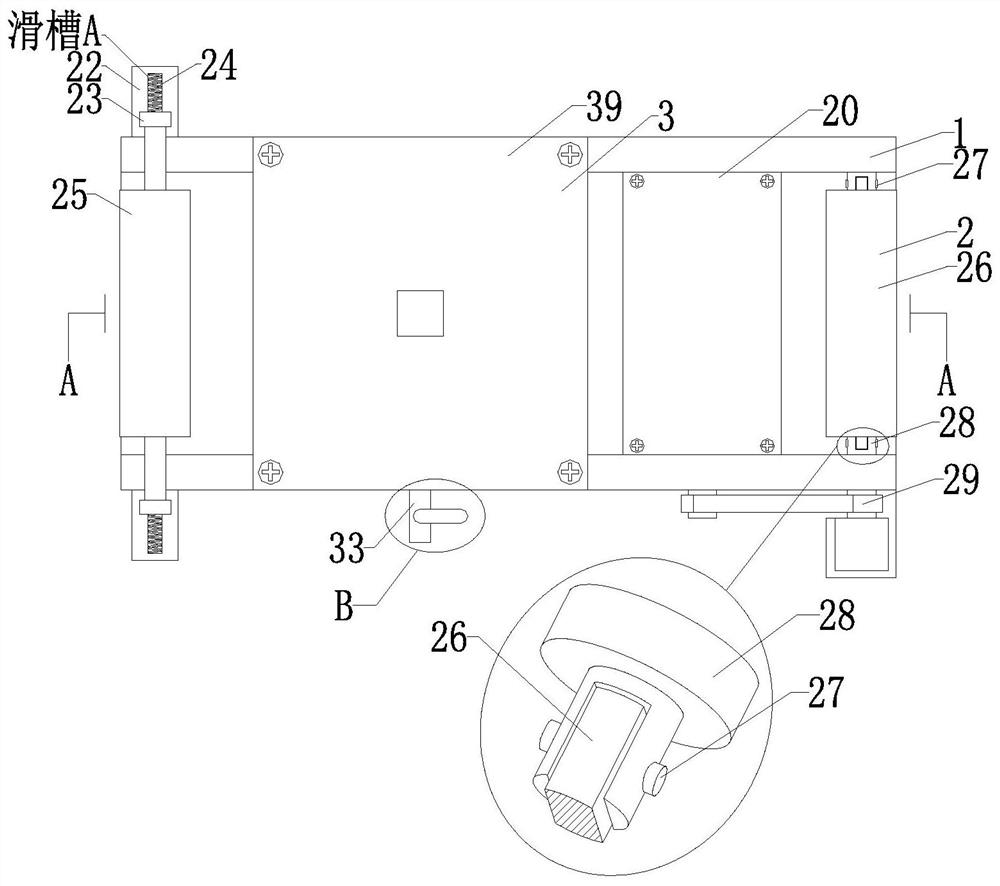

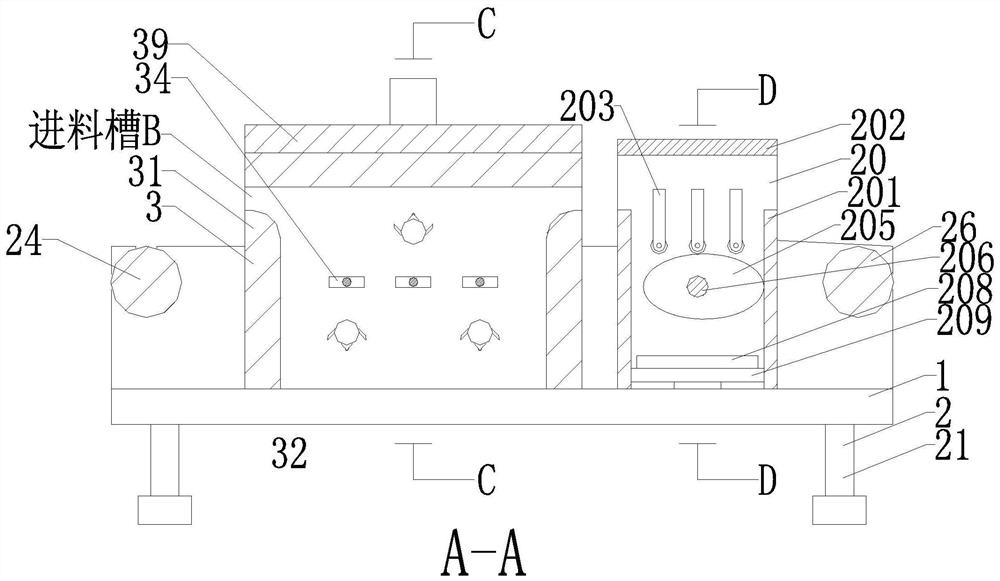

[0026]In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 8 , to further elaborate the present invention.

[0027] A production and processing system of polyethylene polypropylene polyester polymer waterproof membrane, including a mounting frame 1, a traction kit 2 and a cooling kit 3, the traction kit 2 is installed on the mounting frame 1, and the cooling kit 3 is installed inside the traction kit 2, wherein:

[0028] The traction kit 2 includes a supporting column 21, a guiding slide 22, a sliding sleeve 23, a pressing spring 24, a feeding rotating column 25, a winding column 26, a connecting pin 27, a rotating block 28, a No. 1 motor, a transmission belt 29 and a shaking The component 20 and the support column 21 are evenly installed on the lower end surface of the installation frame 1 by welding. The guide slide 22 is symmetrically installed on the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com