Tube plate mounting structure of quick-connection type tubular heat exchanger for chemical engineering

A technology of tube-and-tube heat exchanger and installation structure, which is applied to indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., which can solve the inconvenience of timely detection and replacement of heat exchange tubes, increase the labor intensity of staff, and reduce Equipment repair efficiency and other issues, to achieve the effect of convenient detection and replacement operations, improve repair efficiency, and reduce cooling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

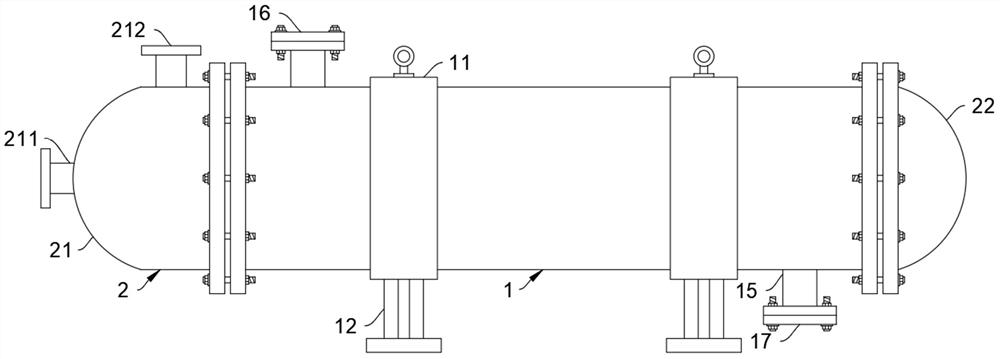

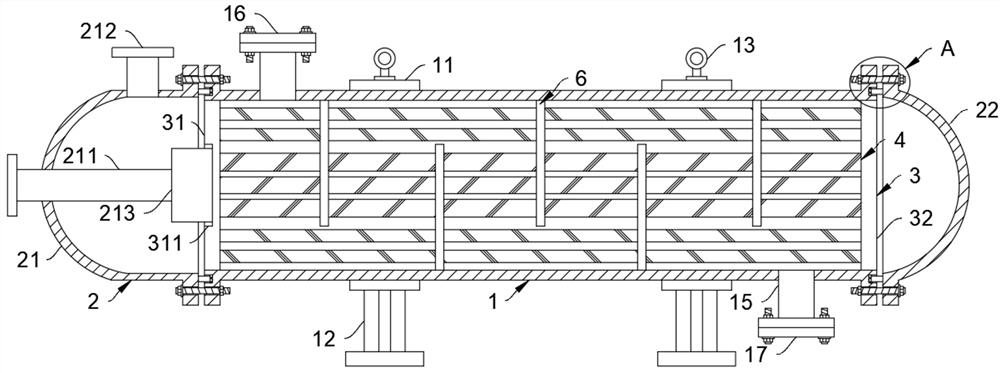

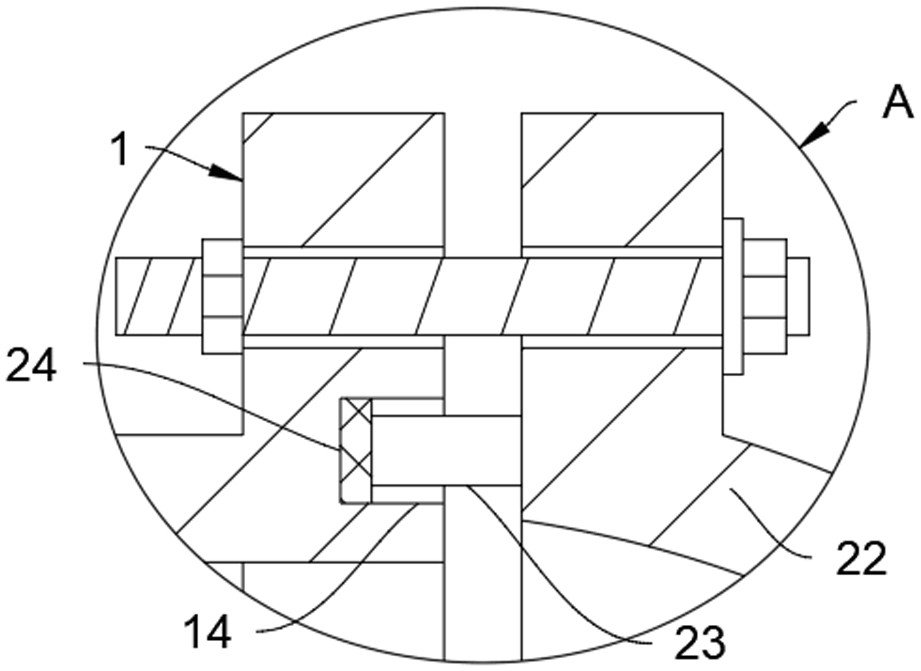

[0029] like Figure 1-6 As shown, a tube-sheet installation structure of a quick-connected tube-and-tube heat exchanger for chemical industry includes a shell 1. It should be noted that the shell 1 adopts a tubular structure, and the middle position of the shell 1 is symmetrically provided with a fixed ring 11. One end of the fixed ring 11 close to the ground is provided with a support 12 for supporting the equipment, and the end of the fixed ring 11 away from the ground is detachably connected with a lifting ring 13, which is convenient for the transfer and hoisting of the equipment and improves the flexibility of the transfer of the heat exchanger.

[0030] The shell 1 is fixedly connected with the pipe box 2 through the flange. It should be noted that the end of the pipe box 2 and the shell 1 close to each other is equipped with a flange, and the flan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com