A kind of hole reaming groove and hole reaming method for wet process black silicon machine

A black silicon, wet process technology, applied in sustainable manufacturing/processing, climate sustainability, semiconductor devices, etc., can solve problems such as unreasonable temperature control of liquid medicine, uneven mixing of liquid medicine, etc., to ensure stability and reliability. The uniformity of appearance, the effect of promoting mixing uniformity, and ensuring the quality of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

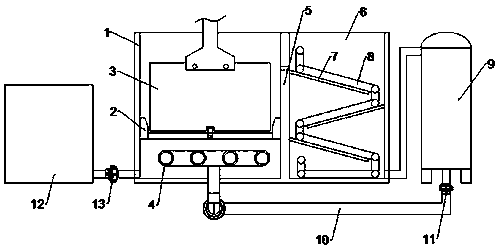

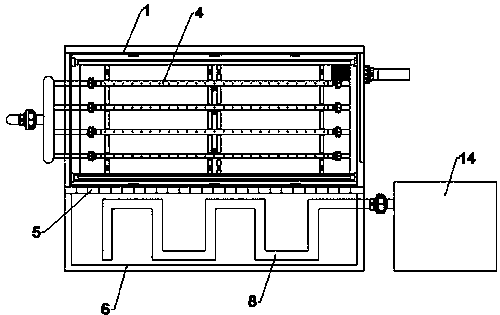

[0031] Based on the above-mentioned reaming tank for wet-process black silicon machine, the present invention also discloses a method for reaming holes of wet-process black silicon, which is specifically as follows:

[0032] (1) First, place the black silicon neatly in the flower basket, put the flower basket into the main tank at a speed of 2-5cm / s, set the lower end nested on the positioning frame, and then soak in the main tank for 10-30s Finally, lift the flower basket, and then soak the next set of black silicon;

[0033] (2) After soaking 5 to 15 groups of black silicon, add liquid to the main tank through the liquid replenishment tank. At this time, the amount of liquid in the main tank increases so that it overflows from the top of the baffle to the auxiliary tank;

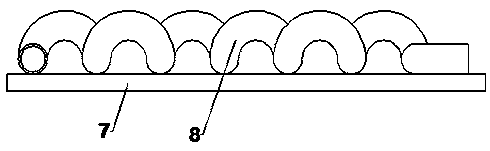

[0034] (3) The liquid that overflows into the auxiliary tank flows sequentially on the deflector, and during the flow, it contacts the capillary tube equipped with cooling water to cool down, and finally t...

Embodiment 2

[0038] The difference between this embodiment and Embodiment 1 lies in: In step (1), the flower basket is put into the main tank at a speed of 5-15 cm / s, and soaked for 30-60 s.

Embodiment 3

[0040] The difference between this embodiment and embodiment 2 is that in step (1), the flower basket is put into the main tank at a speed of 15-25 cm / s, and soaked for 60-120 s.

[0041] Comparing the black silicon structures made based on the above three examples, it is concluded that in Example 1, due to the short immersion time, the reaction on the surface of the black silicon is not sufficient; in Example 3, due to the faster placing speed, the disturbance of the liquid is reduced The aesthetics of the black silicon surface, so embodiment 2 is the best embodiment, the flower basket placement speed is 5-15cm / s, and the soaking time of the black silicon is 30-60s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com