X-ray source and method for producing x-rays

A Roentgen ray and Roentgen radiation technology, applied in the field of Roentgen ray sources, can solve problems such as high wear and low mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

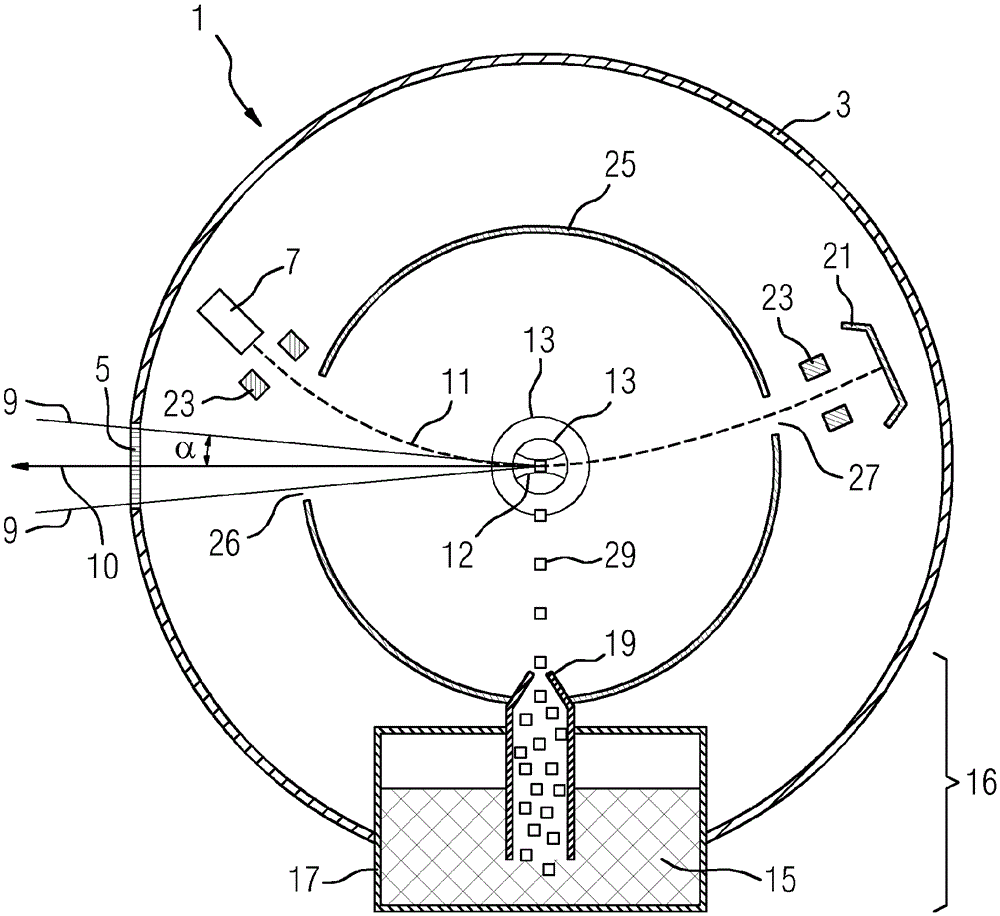

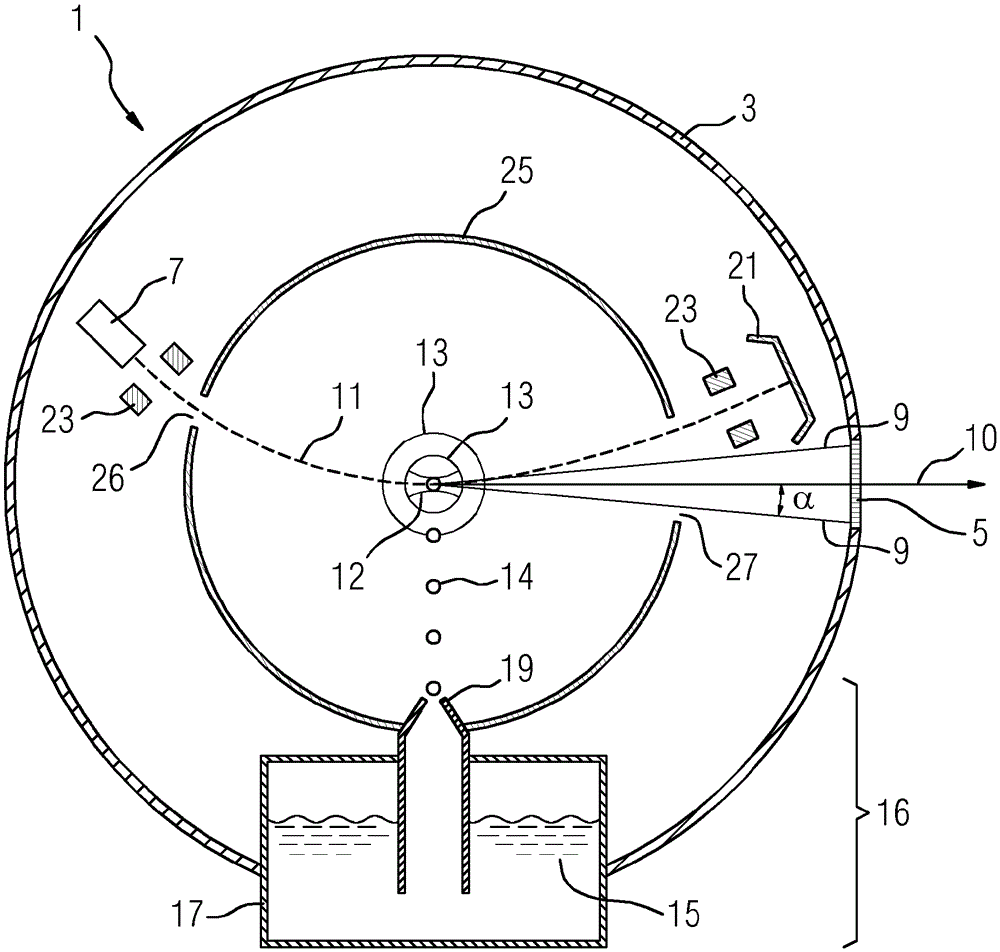

[0036] exist figure 1 A schematic cross-section of a roentgen ray source 1 according to a first embodiment of the invention is shown in . An evacuatable outer housing 3 is shown, which has a circular cross section. The outer housing 3 can be designed, for example, as a hollow sphere or as a hollow cylinder. The creation of a vacuum in the housing 3 is a prerequisite for the emission of electrons into this space and the acceleration of the electrons in the direction of the predetermined position. The outer housing 3 is provided with a beam exit window 5 for coupling out the generated Roentgen radiation 9 from the Roentgen source 1 . The beam exit window 5 is also sealed vacuum-tight with respect to the outer housing 3 . Suitable materials for beam exit window 5 are, for example, beryllium or aluminum.

[0037] Arranged in the evacuatable space are an electron source 7 , a vapor vessel 25 with an inlet opening 26 and an outlet opening 27 , and a collector 21 . The electron ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com