Automatic packaging card screening machine

An automatic screening and automatic diversion technology, applied in sorting and other directions, can solve the problem of large screening workload of packaging cards, and achieve the effects of fast screening, low error rate and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

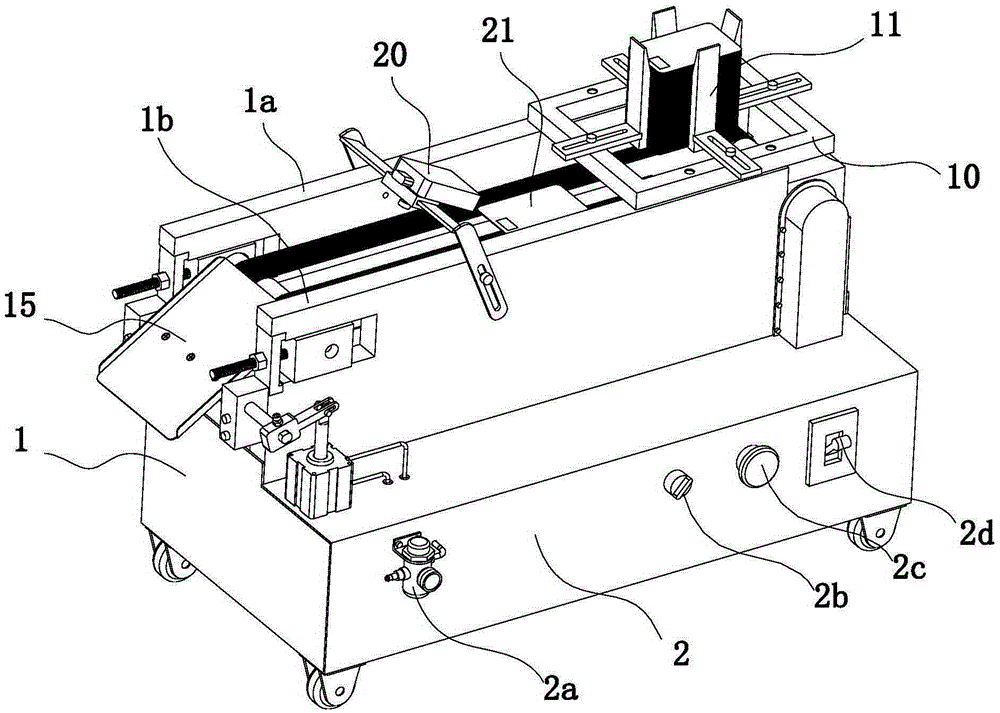

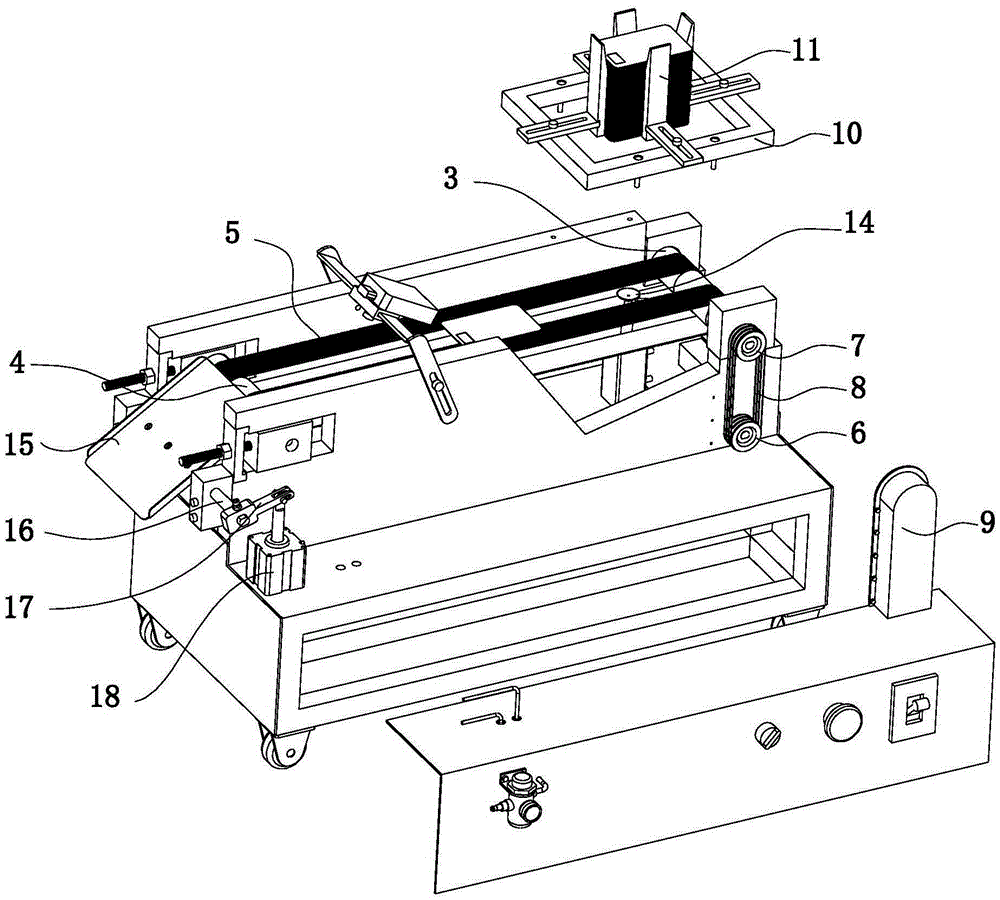

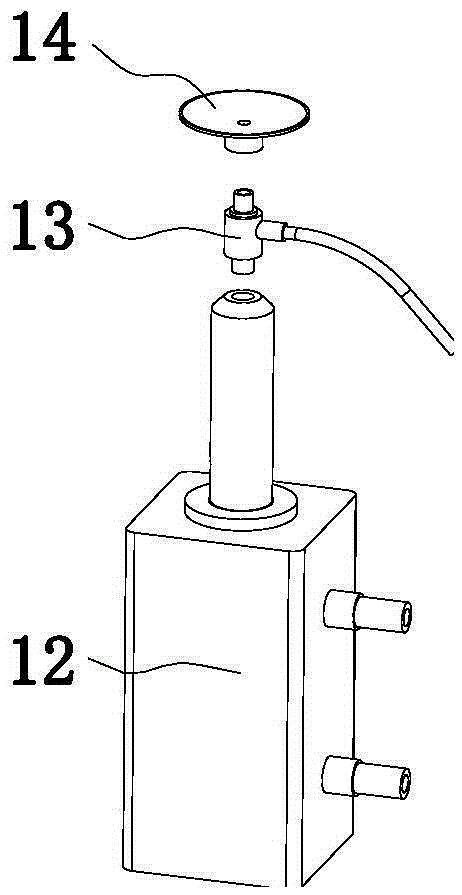

[0023] refer to Figure 1 to Figure 4 The shown automatic screening machine for packaging cards includes a frame 1 and a control cabinet 2 located at the side of the frame 1, the frame 1 is provided with a left support plate 1a and a right support plate 1b perpendicular to the ground and parallel to each other; A material transmission device is installed in the frame 1; the material transmission device is provided with two conveyor belts 5 that are horizontally arranged between the left support plate 1a and the right support plate 1b and rotate synchronously; There is a gap; the top of the frame 1 is detachably installed with a material stacking frame located above the feed end of the conveyor belt 5; the material stacking frame is provided with a discharge opening facing the gap; A reclaimer positioned directly be...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap