A composite cold-pressed synthetic adhesive roller

A synthetic rubber, composite technology, applied in the direction of rollers, conveyor objects, transportation and packaging, etc., to achieve the effect of being rich in elasticity, avoiding welding deformation, and enhancing coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

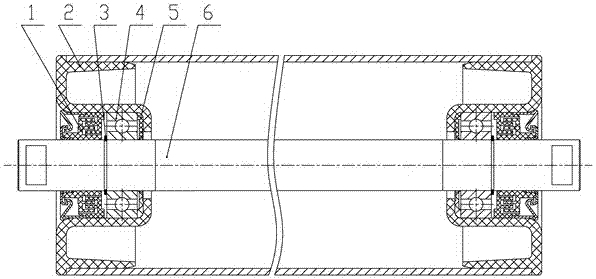

[0020] With reference to the attached drawings, a composite cold-pressed synthetic adhesive roller includes a combined sealing device 1, a pipe seat 2, a retaining ring 3, a bearing 4, an isolating ring 5, and a shaft 6. The shaft 6 penetrates the pipe seat 2 and is positioned on the shaft 6. The two ends of the 6 are equipped with the isolation ring 5 and the bearing 4, and the bearing 4 is fixed on the two ends of the shaft 6 with the retaining ring 3; the combined sealing device 1 is inserted into the two ends of the shaft 6 through the shaft 6 and the pipe seat 2 in interference connection.

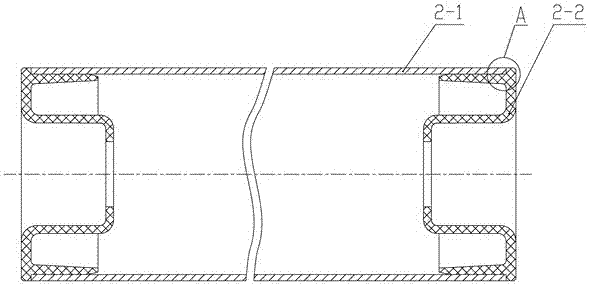

[0021] The said tube holder 2 is integrated by the tube 2-1 and the bearing seat 2-2 by cold-pressing synthetic glue. The material of the tube 2-1 is the ultra-high-precision roller special longitudinally welded steel pipe, which has been treated with rust prevention inside and outside the tube. Manufactured; the bearing seat 2-2 is made of polyoxymethylene and is formed by one-time injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com