Arrangement form of balance weight on balance arm of tower crane with luffing boom

A technology of balance arms and tower cranes, which is applied to cranes and other directions, can solve problems such as balance arms occupying more space for rotation, unfavorable production management and inventory control, difficult installation and disassembly of counterweights, etc., so as to facilitate production and management, and facilitate Good effect on production management and inventory control, safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

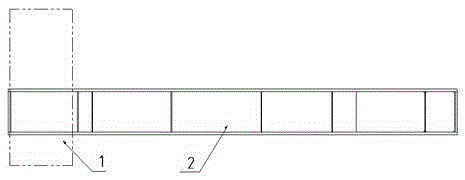

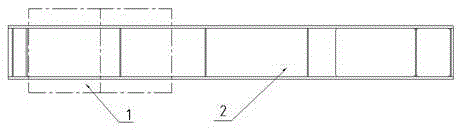

[0018] Such as figure 2 As shown, the counterweight 1 of the present invention is suspended at the middle and rear part of the balance arm 2, and is located between the two main girders of the balance arm 2. The counterweight 1 is limited and fixed by the main girder, and the counterweight 1 is suitable for cement counterweights. , cast iron counterweight can be, the same form of the product. The installation mechanism connected with the main beam can be placed above the counterweight 1, effectively shortening the length of the balance arm 2, and the counterweight 1 will not occupy additional length space. And there are main beams and tail beams around the counterweight 1, which is convenient for operators to move.

[0019] The present invention adopts the layout structure of the universal balance arm 2, arranges the counterweight 1 inside the balance arm 2, adopts the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com