Water-based UV base oil and preparation method thereof

A water-based, primer technology, used in coatings, conjugated diene coatings, polyether coatings, etc., can solve the problems of high cost, poor use effect, and poor adhesion of UV varnish for UV printing overcoat. To achieve the effect of excellent adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

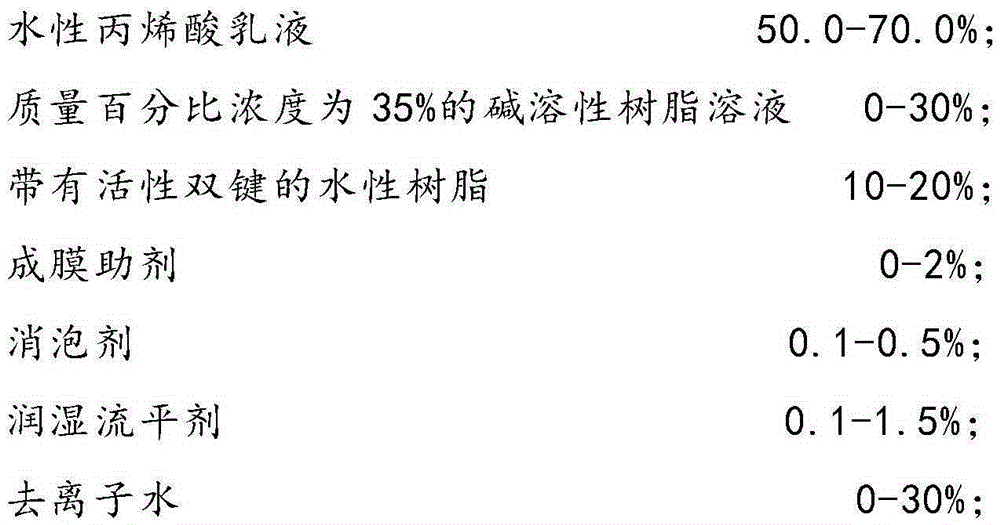

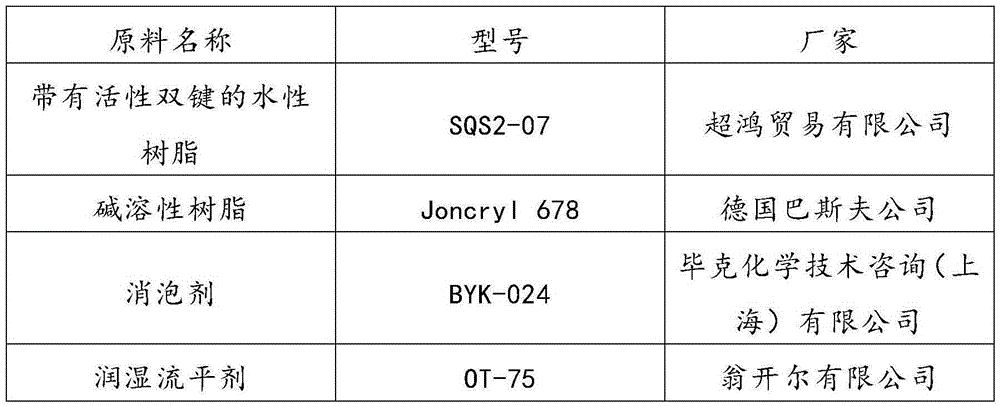

Method used

Image

Examples

Embodiment 1

[0052] First mix 40% of water-based acrylic emulsion A and 15% of water-based acrylic emulsion B, pour the mixed water-based acrylic emulsion into a clean container at a stirring speed of 500-800r / min, and add 15% of the mass percentage in turn 35% alkali-soluble resin solution, 16% SQS2-07, 0.5% defoamer and 1.5% wetting and leveling agent, stirring at a stirring speed of 800-1200r / min for 0.5-1h; Slowly add 2% diethylene glycol monobutyl ether film-forming aid and 10% deionized water dropwise, stir and defoam at a speed of 300-500r / min, filter and pack with 200 mesh, and obtain the finished water-based UV primer.

Embodiment 2

[0054] First mix 40% water-based acrylic emulsion A and 28% water-based acrylic emulsion B, pour the mixed water-based acrylic emulsion into a clean container at a stirring speed of 500-800r / min, and add 10% mass percentage concentration 35% alkali-soluble resin solution, 8% polyethylene glycol diacrylate, 0.5% defoamer and 1.5% wetting and leveling agent, stirring at a stirring speed of 800-1200r / min for 0.5-1h ; Then slowly add 2% diethylene glycol monobutyl ether film-forming aid and 10% deionized water dropwise, stir and defoam at a speed of 300-500r / min, filter and pack with 200 meshes, and obtain a water-based UV base oil finished product.

Embodiment 3

[0056] First mix 40% of the water-based acrylic emulsion A and 15% of the water-based acrylic emulsion B, pour the mixed water-based acrylic emulsion into a clean container at a stirring speed of 500-800r / min, and add 15% concentration by mass in turn 35% alkali-soluble resin solution, 16% styrene-butadiene latex, 0.5% defoamer and 1.5% wetting and leveling agent, stirring at a stirring speed of 800-1200r / min for 0.5-1h; then slowly Add 2% diethylene glycol monobutyl ether film-forming aid and 10% deionized water dropwise, stir and defoam at a speed of 300-500r / min, filter and pack with 200 mesh, and obtain the finished water-based UV primer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com