A scanning cycle power supply electric heating system for melting ice and snow bridge deck

A scanning, electrothermal technology, applied in bridges, bridge parts, pavement details, etc., can solve the problems of power shortage, prevent the popularization and application of electric heating, snow melting and ice melting, and control, and achieve convenient detection and maintenance, early investment and later operation costs. The effect of reducing, total power guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

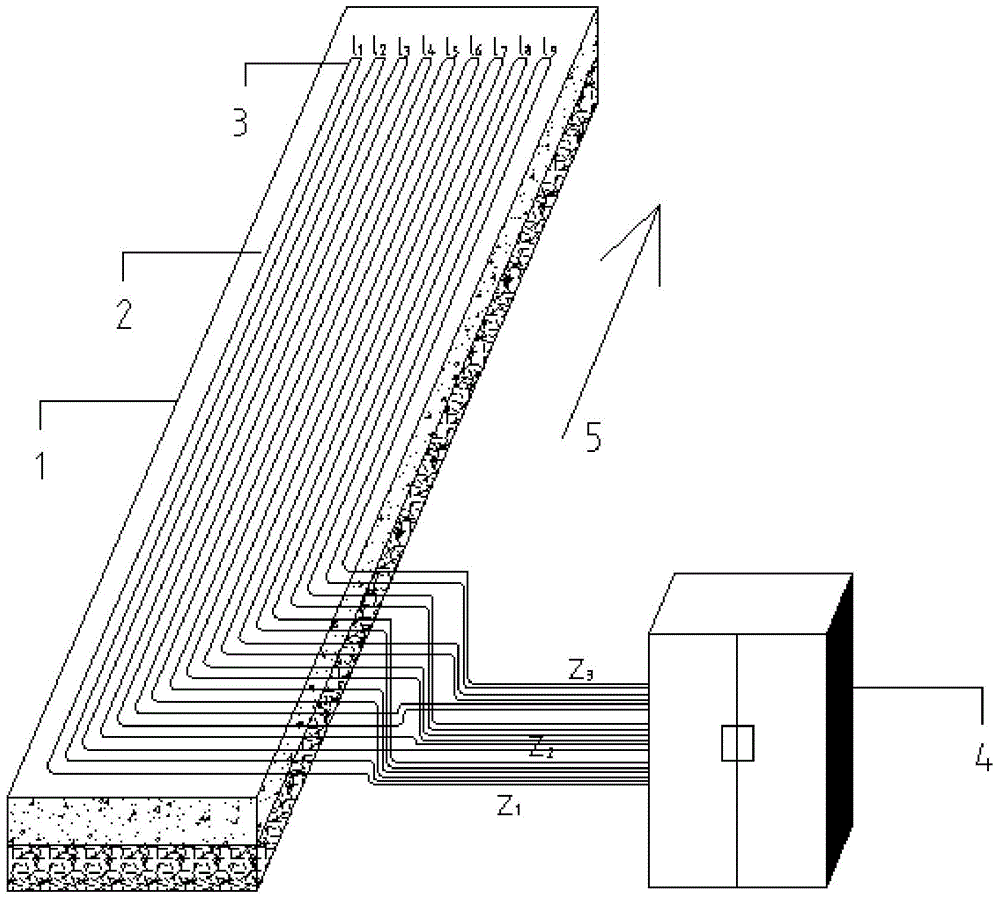

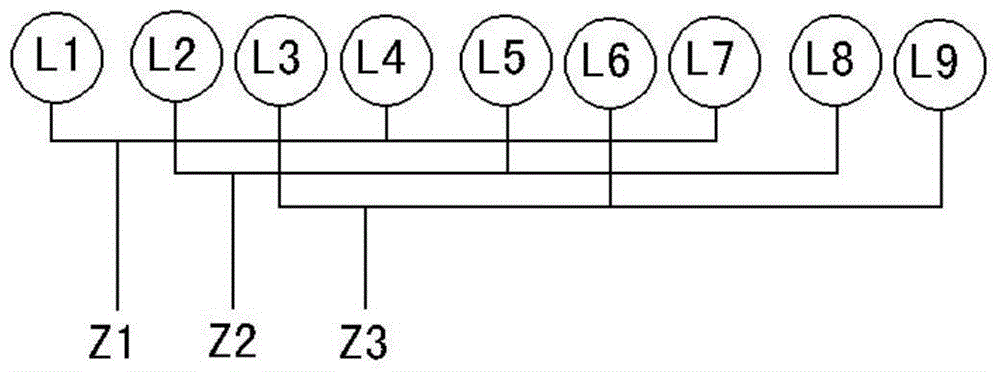

[0032] see figure 1 In this embodiment, the structure of the ice and snow melting bridge deck electric heating system with scanning cycle power supply is set as follows: the bridge deck ice and snow melting electric heating system is divided into independent and controllable parallel electric heating units according to the power load capacity, and each electric heating unit is along the direction of vehicle travel. Arrange in parallel at a set interval to form a longitudinal array, and control the grouping of each electric heating unit in the longitudinal array to work in a set time sequence cycle in the form of scanning.

[0033] In the specific implementation, each electric heating unit is marked as L1, L2...Ln in sequence of natural numbers from one side of the longitudinal array to the other side; said n is the number of electric heating units in the longitudinal array; the n electric heating units are divided into s Electric heating unit groups, and each electric heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com