Blowout preventing hole opener for casing pipe

A technology of hole opener and casing, applied in the direction of wellbore/well components, earthwork drilling and production, etc., which can solve the problems of inapplicability, long pressure relief time, and easy fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

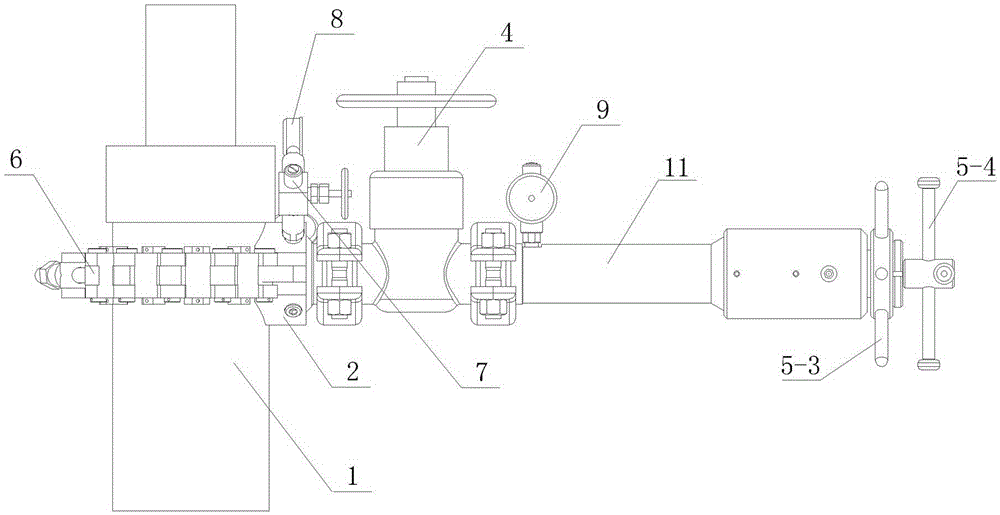

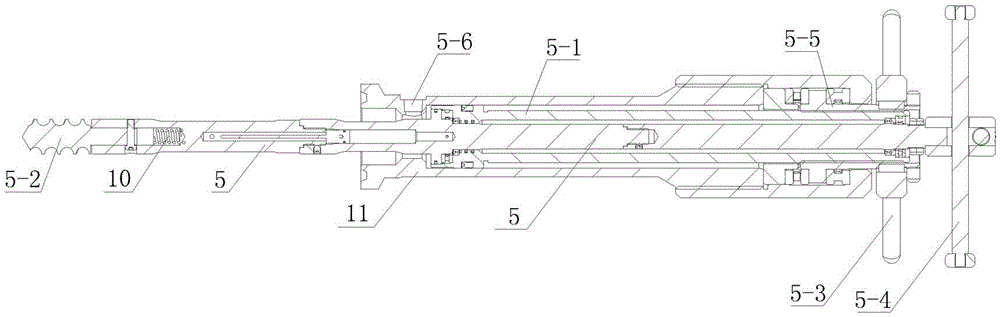

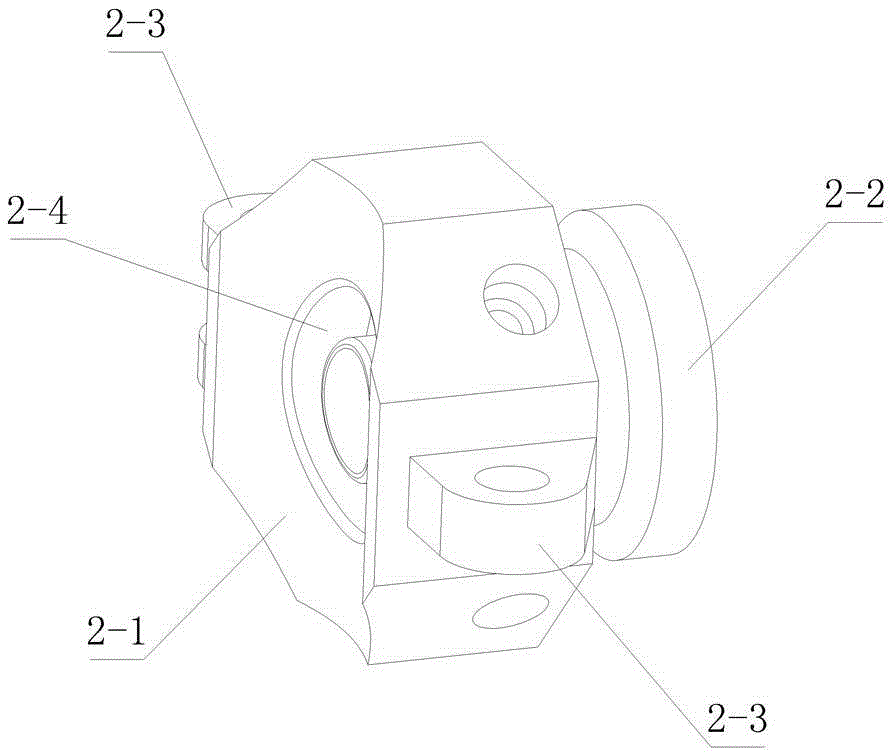

[0012] A casing blowout-proof hole opener, the structure includes a pressure sleeve type pipe joint 2 fixed by a safety slip 6 arranged on the side wall of the casing 1, followed by a gate valve 4 and a detachable drilling device connected in sequence , the key lies in: the pressure sleeve type pipe joint 2 is pressurized and locked on the side surface of the casing 1 by means of the safety slip 6, and the seal is realized by means of the sealing pressure sleeve 3 embedded in the end; the other pressure sleeve type pipe joint 2 The end face is provided with a clamp connector 2-2, which is positioned and connected with the gate valve 4 to form a working channel for the drill sleeve and the drill bit.

[0013] One end of the pressure sleeve type pipe joint 2 is an intersecting surface 2-1 matching the side of the casing 1, and the flange type clamp connector 2-2 at the other end is connected to the pipe joint of the gate valve 4 by means of a high-pressure clamp. The connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com