Cylinder body water jacket with orifice plug and engine cylinder body

A cylinder water jacket and throttle plug technology, applied in the direction of engine components, machines/engines, cylinders, etc., can solve the problems of reducing coolant flow rate and water pressure, uneven coolant flow, and reducing cooling effect, etc., to achieve improved Flow rate and water pressure, improved cooling effect, uniform flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

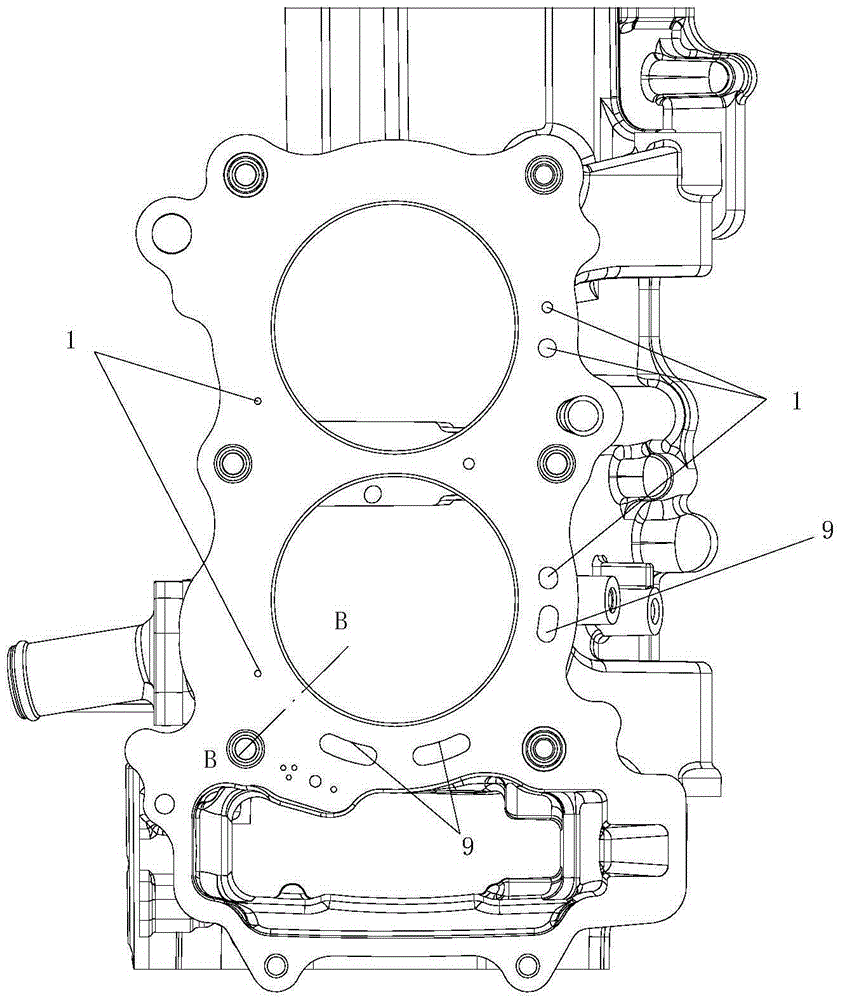

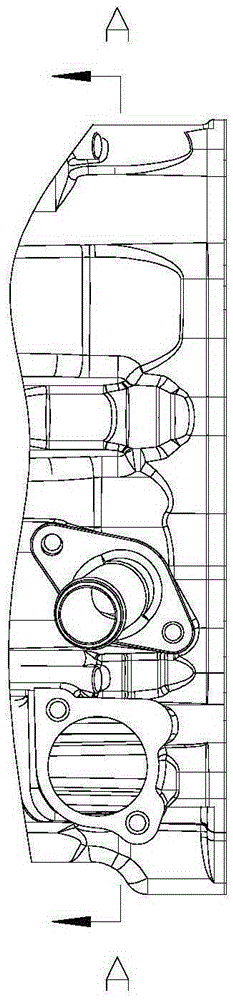

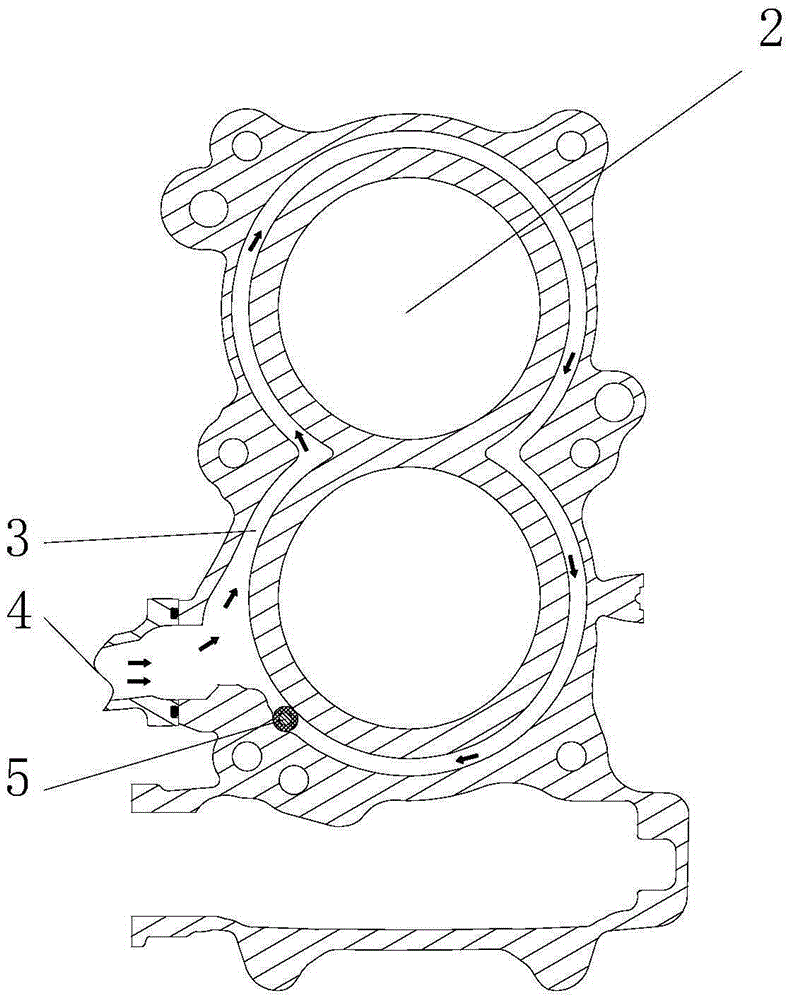

[0019] figure 1 It is a structural schematic diagram of the present invention; figure 2 for figure 1 left view of image 3 for figure 2 Sectional view at A-A in the middle. As shown in the figure, the cylinder water jacket with a throttle plug in this embodiment includes an annular flow channel 3 arranged around each cylinder hole 2 and a water inlet 4 communicated with the annular flow channel 3 and arranged in the cylinder body. Water outlet; the annular flow channel 3 is provided with a throttling plug 5 that allows the cooling liquid to flow in one direction along the annular channel 3. Thereby blocking a flow channel of the cooling liquid, so that the cooling liquid can only go around the annular flow channel 3 one-way flow channel (that is, flow clockwise or counterclockwise around the annular flow channel 3), because a part of the cooling liquid needs to flow away from the water inlet The cylinder block at the 4th end enters into the water jacket of the cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com