Pipe fitting connecting structure and installation method thereof

A technology of connection structure and installation method, which is applied in the direction of pipes/pipe joints/fittings, pipe supports, mechanical equipment, etc., can solve the problems of reducing production and construction costs, complicated operation, and increasing engineering costs, so as to reduce production and construction Low cost, reduced production cost, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

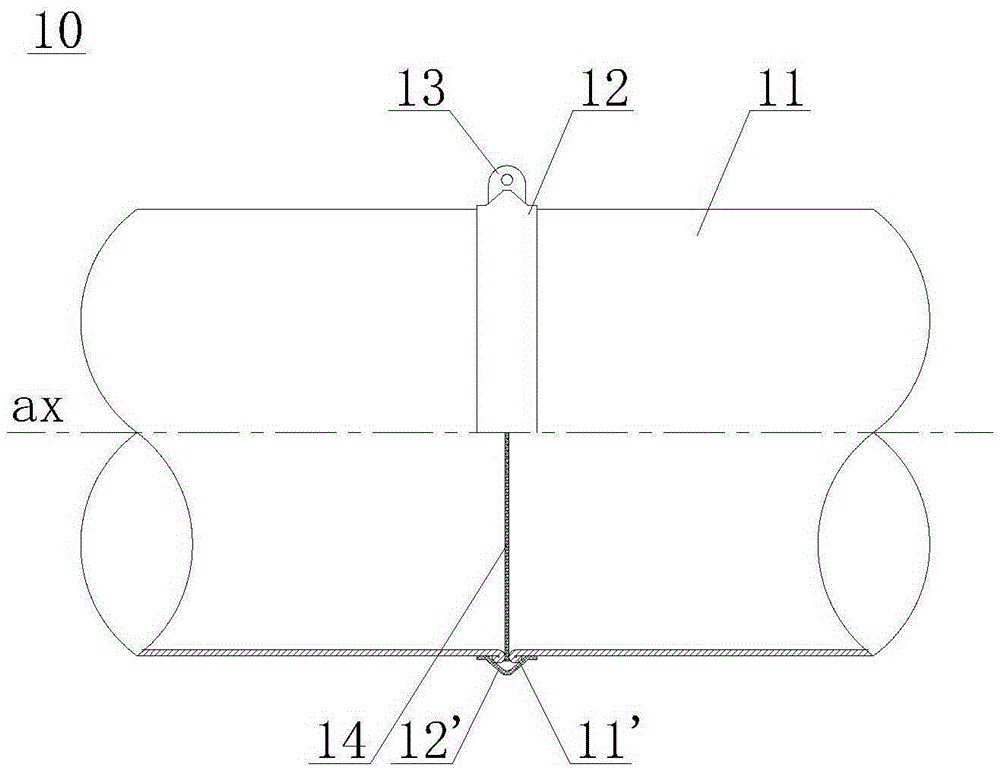

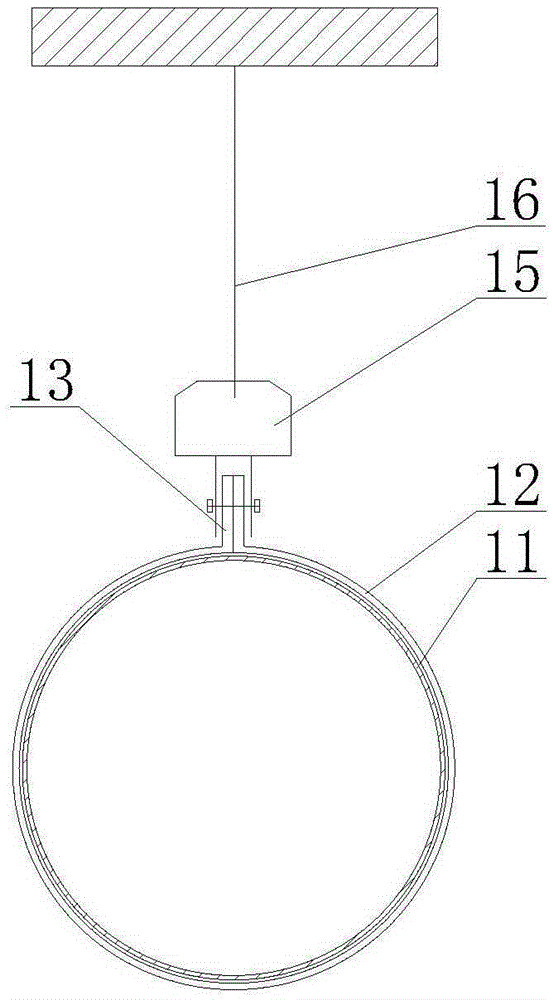

[0021] Example 1: Combining figure 1 and figure 2 Describe the pipe fitting connection structure 10 of the present invention, which includes a ring-shaped hoop main body 12 that can cover the outer wall of the pipe fitting 11; a pair of locking lugs 13 are fixed at the end of the hoop main body 12, so that the hoop The main body 12 can be tightly wrapped and fixed on the pipe fitting 11; the two pipe fittings 11 with crimping 11' at the end are butted, the hoop main body 12 has a notch 12' with a V-shaped cross section, and the roll of the two pipe fittings 11 The edge 11' is buckled in the notch 12'.

[0022] In the pipe fitting connection structure 10 of the present invention, the ends of the two pipe fittings 11 that are butted are crimped. 11' is buckled in the notch 12' surrounded by the hoop main body 12, and the hoop main body 12 is locked to the outer wall of the pipe fitting 11 through the lug 13 fixed at the end of the hoop main body 12, thereby stably connecting ...

Embodiment 2

[0028] Embodiment 2: Combination figure 1 and figure 2 Illustrate the installation method of pipe fitting connection structure 10 of the present invention, concrete steps are as follows:

[0029] 1. Crimping the ends of the pipe fittings 11 and connecting two adjacent pipe fittings 11;

[0030] 2. Set the hoop main body 12 between two adjacent pipe fittings 11, make the crimping 11' of the two pipe fittings 11 that are connected to each other buckle in the notch 12' of the hoop main body 12, and tighten the hoop Lug 13 of hoop body 12 .

[0031] In the installation method of the pipe fitting connection structure of the present invention, since the crimping treatment of the pipe fitting 11 and the hoop main body 12 are both processed and formed in the factory at one time, during the installation process, only the hoop main body 12 needs to be sleeved on two adjacent Between the curling edges 11' of the pipe fittings 11, the V-shaped notches 12' of the hoop main body 12 clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com