A detection circuit and detection method of an inductive displacement sensor

A displacement sensor and detection method technology, applied in the field of sensor detection, can solve the problems of inability to obtain the precise inductance of the sensor coil, poor environmental temperature resistance, etc., and achieve the effects of improving reliability, reducing power consumption, and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

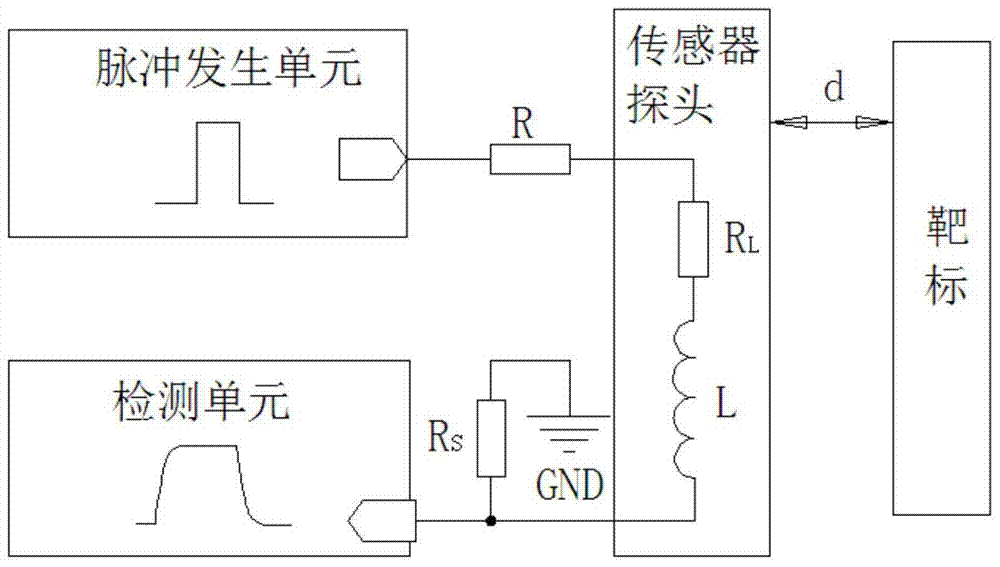

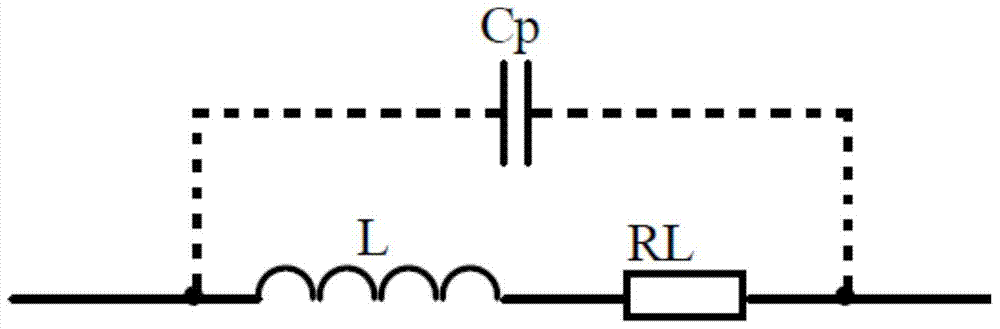

[0076] The internal resistance R of the nominal coil of the sensor at room temperature 20°C L is (12~14)Ω, when the ambient temperature changes between (-55~+70)℃, the coil internal resistance R L The distribution range of temperature drift is (10~16)Ω. When the target displacement is 4mm, the nominal inductance L of the coil is The sensor works in the close state; when the displacement of the metal target is 6mm, the change of the coil inductance relative to the inductance of 4mm is distributed in (80-120)μH, and the sensor works in the far away state.

[0077] Based on the above indicators, taking into account the emission interference and its own anti-interference ability of the present invention, the maximum excitation voltage U of the zero-state response of the coil is set m The value is 2V DC, the value of the current limiting resistor R is 47Ω, and the sampling resistor R S The value is 100Ω, and the maximum flow current of the sensor coil is about 12.5mA. The exci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com