Image de-noising method for coarse austenite stainless steel welding line ultrasonic detection

An ultrasonic detection and ultrasonic image technology, applied in the field of image noise reduction, can solve the problems of enhancing the signal-to-noise ratio of defects in ultrasonic images of coarse-grained austenitic welds, low signal-to-noise ratio of defects, and strong structural noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

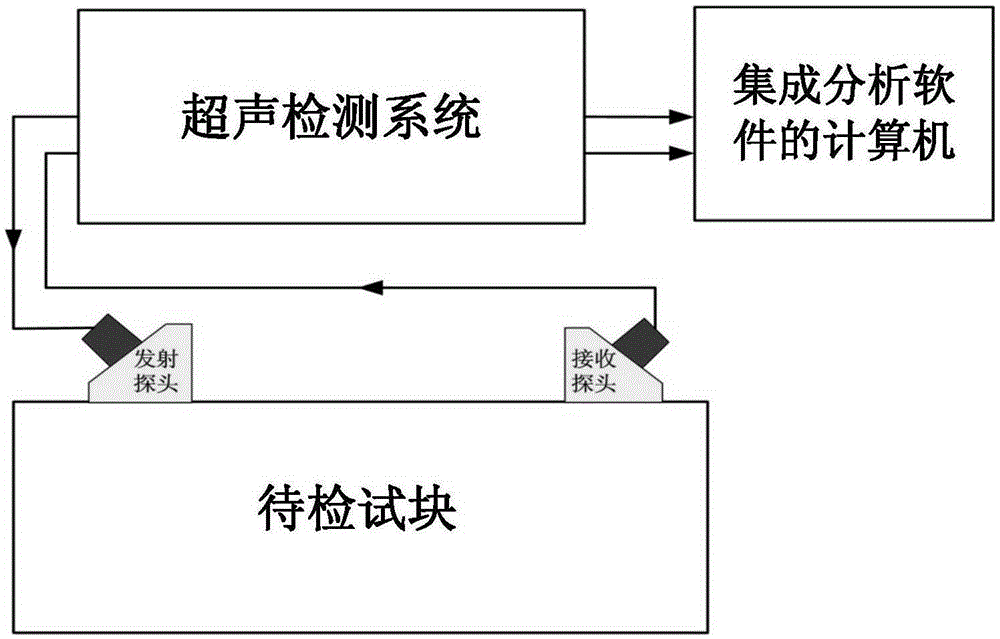

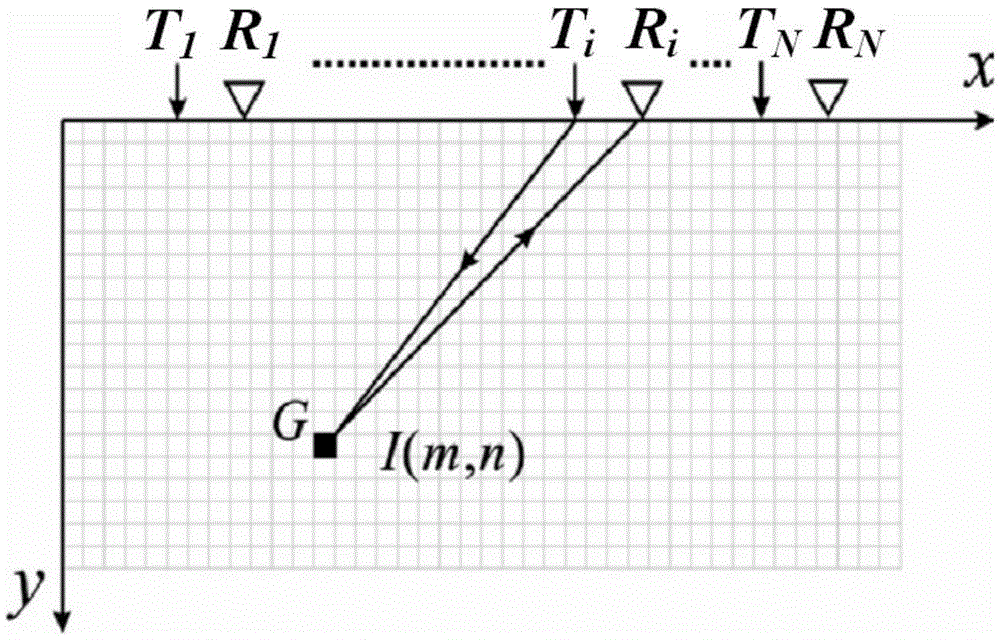

[0042] An image noise reduction method for ultrasonic testing of coarse-grained austenitic stainless steel welds, using ultrasonic testing systems such as figure 1 As shown, it includes an ultrasonic detector, a computer integrated with routine analysis function software, a send-and-receive mode ultrasonic probe, etc. The specific measurement and processing steps are as follows:

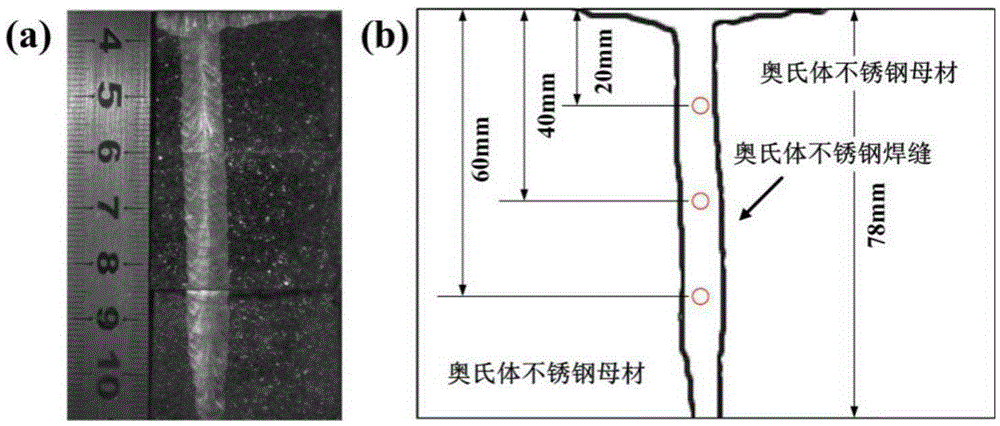

[0043] (1) The block to be tested. The narrow-gap austenitic stainless steel weld and base metal test block of the nuclear power main pipeline were selected as the research objects to verify the noise reduction effect of the phase standard deviation weight algorithm. The section of the test block was intercepted, cut, polished, and polished, and the axial-radial section of the test block was electrolytically corroded with 10% oxalic acid solution to obtain the following: figure 2 (a) Macroscopic metallographic structure shown. It can be seen from the figure that the weld in the test block is comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com