Intelligent auxiliary control system group screen method capable of realizing front wiring of screen cabinet

A front wiring, intelligent technology, applied in switchgear, electrical components, supervision desk/panel, etc., can solve the problem of limited space in the cabin, and achieve the effect of simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

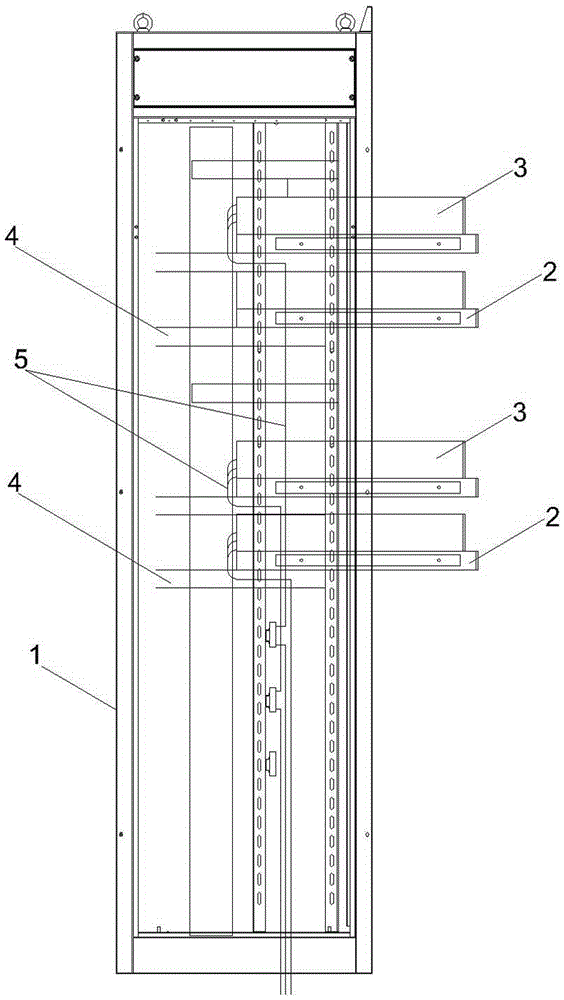

[0011] see figure 1 Firstly, a multi-layer extractable tray 2 is set in the screen cabinet 1, and the draw-out direction of the tray 2 faces to the side, and then the computer, display, lighting intelligent control unit, power environment control unit, network switch, station-side video processing unit, integrated power supply The screen assembly devices 3 are respectively placed on the corresponding trays 2, so that the push-in and extraction of the screen assembly devices 3 can be facilitated, and a horizontal wiring trough 4 is set under the tray 2, and the wiring trough 4 is arranged in front of the screen cabinet 1. Then lead out the wiring 5 of the screen assembly device 3 such as computer, display, lighting intelligent control unit, power environment control unit, network switch, station-side video processing unit, and integrated power supply from the horizontal wiring groove 4, so that the screen assembly device can be kept The wiring in the extraction process is neat....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com