Radial permanent magnet suspension impact type direct-connected micro-hydro generator

An impact type and magnetic levitation technology, which is applied in the direction of impact type engines, hydroelectric power generation, engine components, etc., can solve the problems of high cost and low energy conversion rate, and achieve the effects of prolonging service life, high power generation efficiency, and reducing friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

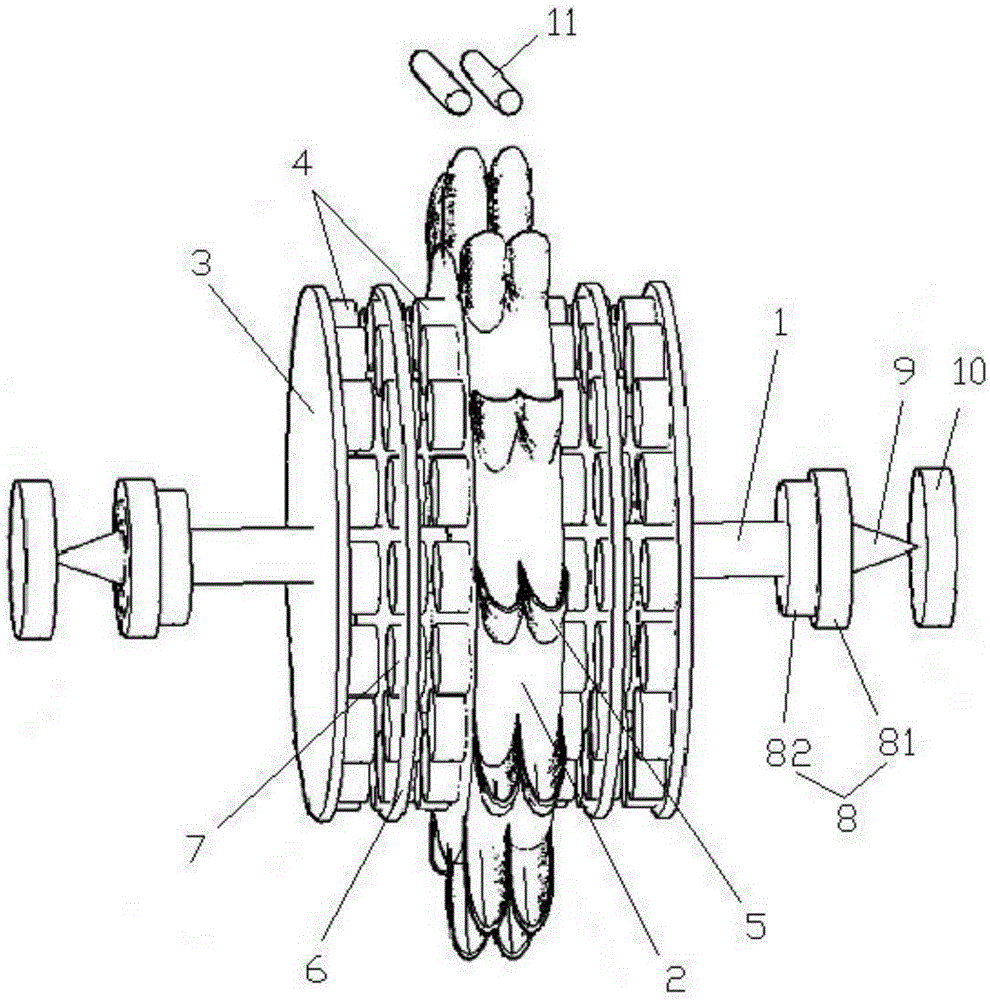

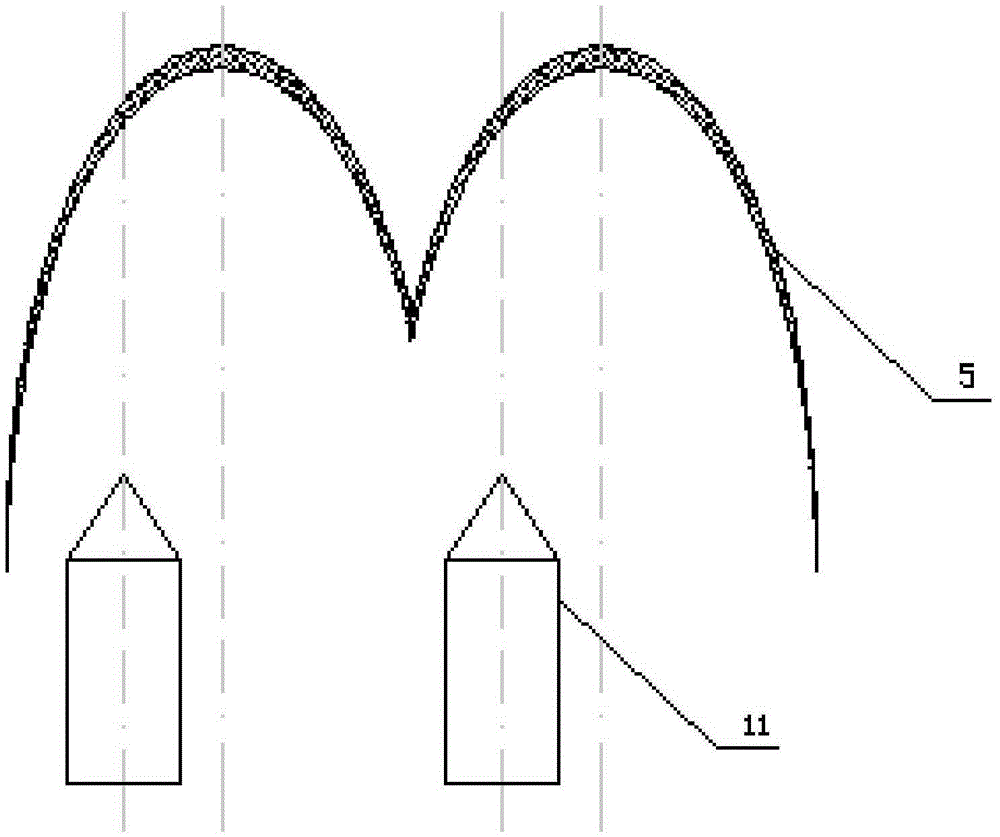

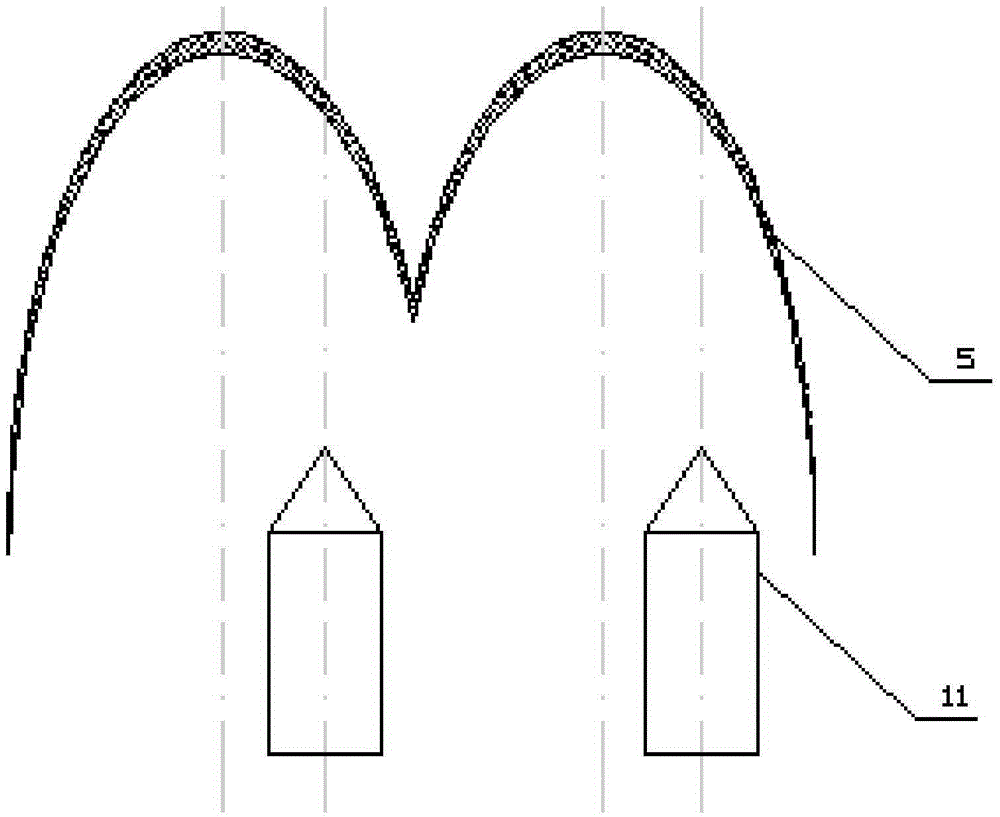

[0021] As shown in the figure, the radial permanent maglev impact type direct-coupled micro-water generator in this embodiment includes a casing and a rotor shaft 1, and a runner 2 and a disc rotor 3 are fixedly arranged on the rotor shaft. The end face of the rotor is provided with circular rotor magnets 4 uniformly arranged along the circumference, and water buckets 5 are uniformly arranged on the outer diameter cylindrical surface of the runner, and the inner cavity of the water bucket is formed by a symmetrical left arc concave Cavity 51 and right arc-shaped concave cavity 52, the cross-section of the inner cavity of the bucket is m-shaped; the casing is fixed with a disc-shaped stator 6, and the end face of the disc-shaped stator has a coreless stator winding 7 ;

[0022] The two ends of the rotor shaft are respectively installed on the casing thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com