Planetary gear set and method for supplying oil to tooth engagement regions and bearings of a planetary gear set of said type

A technology of planetary gear transmission and planetary gear, which is applied in the direction of gear transmission, transmission, transmission parts, etc., can solve problems such as the complex structure of the oil supply device, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

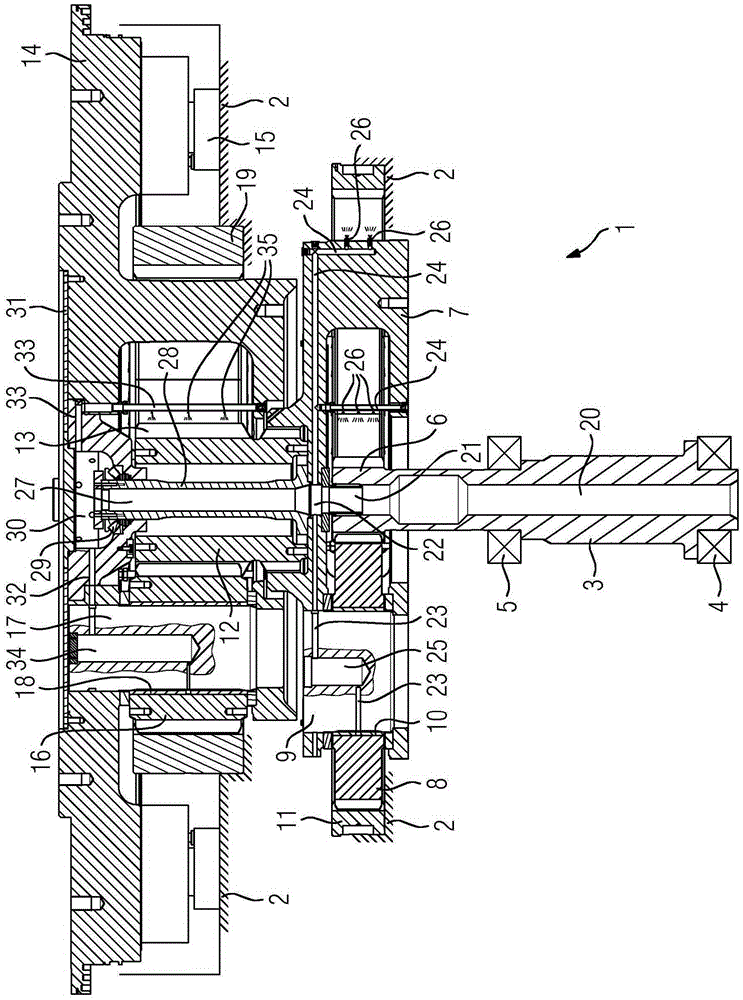

[0024] figure 1 The planetary gear transmission 1 shown in is designed to be two-stage and includes a housing 2, which is shown only partially for the sake of simplification.

[0025] In order to form the first transmission stage, a vertically extending sun gear shaft 3 driven by a motor, not shown further, is rotatably held in the housing 2 by means of corresponding bearings 4 and 5. Currently, the driving of the sun gear shaft 3 is directly realized. Alternatively, the drive can also be achieved indirectly, in particular via a drive shaft guided laterally in the housing 2 which drives the sun gear shaft 3 via a corresponding bevel gear.

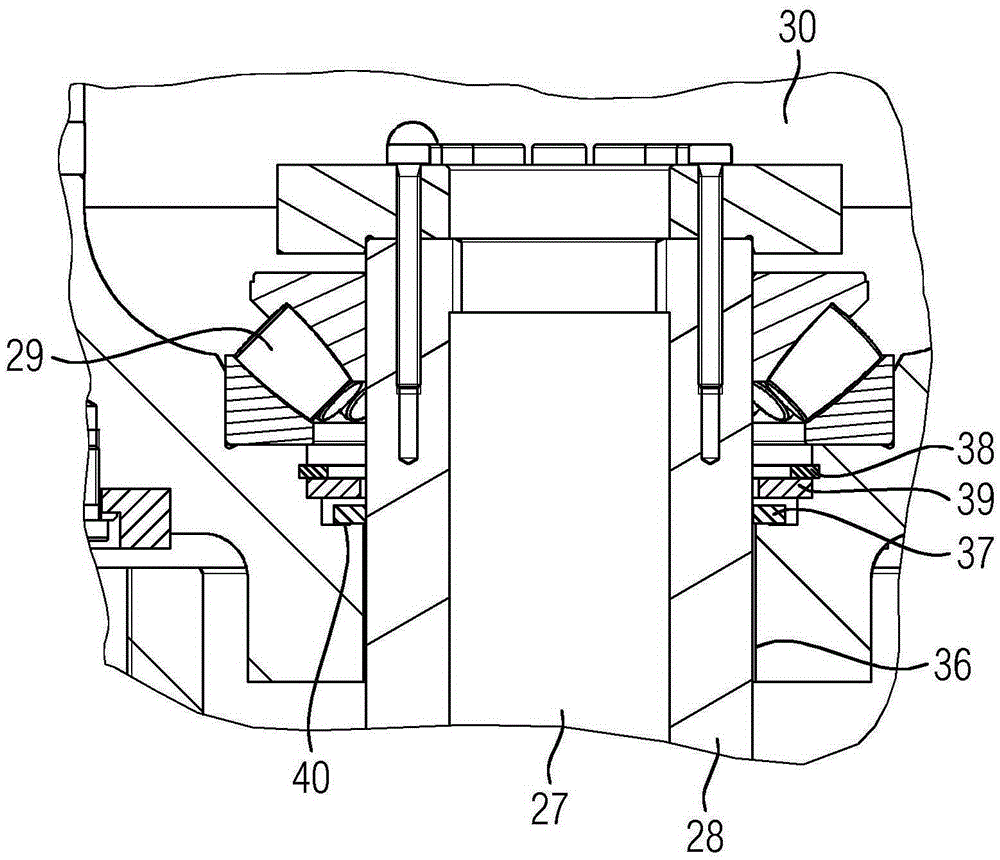

[0026] In the area above the sun gear shaft 3, a sun gear 6 is mounted in a rotationally fixed manner. In addition, a planetary gear carrier 7 is rotatably supported in the housing 2, which accommodates a plurality of gears 8. The fixing of the gear 8 on the planetary gear carrier 7 is achieved by a shaft 9 which is firmly fixed on the planeta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com