Reed Combine Harvester Automatic Cutting and Baling Device

A technology for combine harvesters and bundling devices, which is applied to harvesters, balers, agricultural machinery and implements, etc. It can solve problems such as low production efficiency, increased papermaking costs, and manual labor for reed bundling to achieve automatic control. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

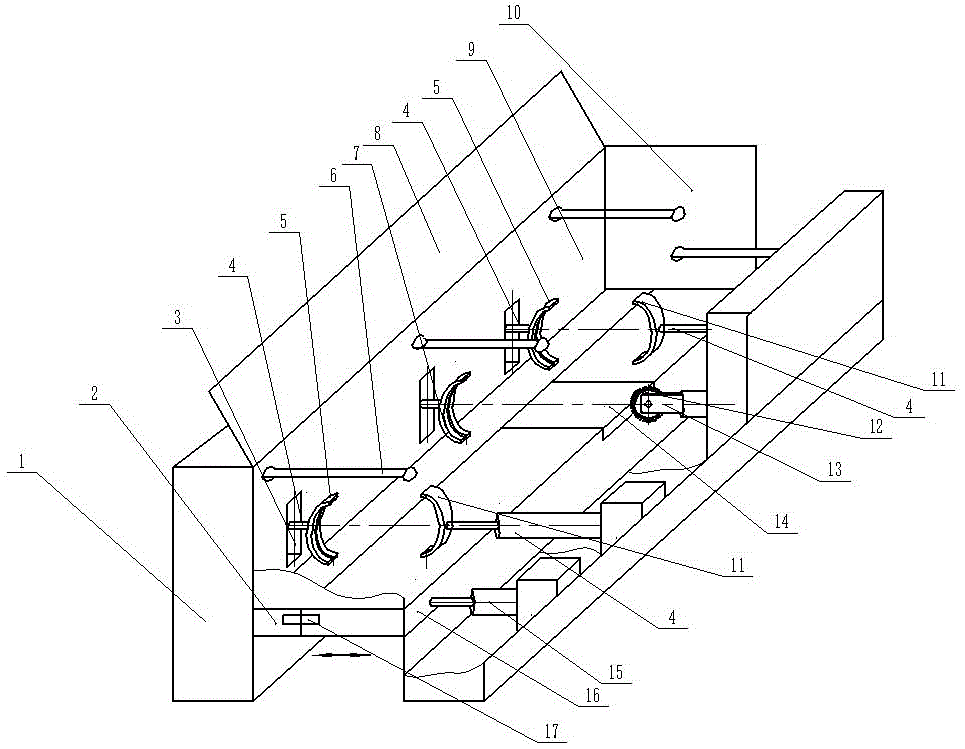

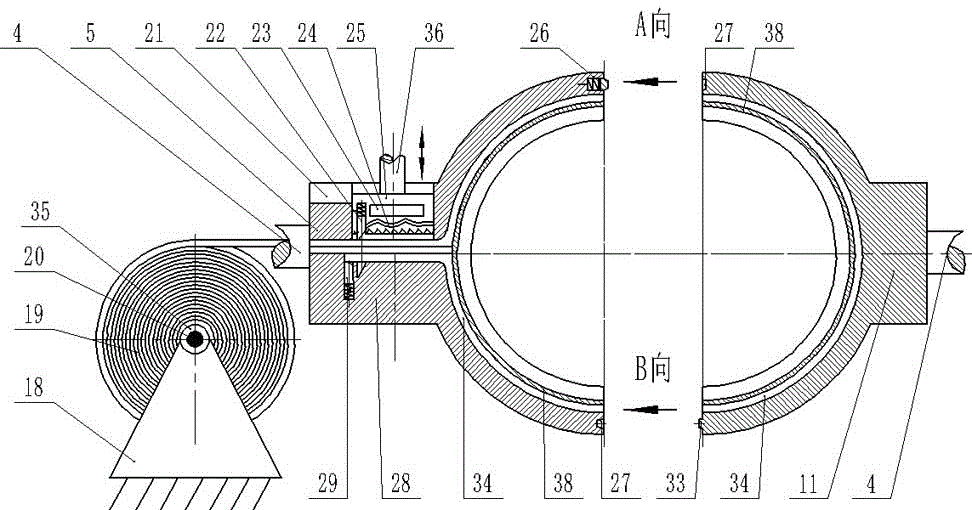

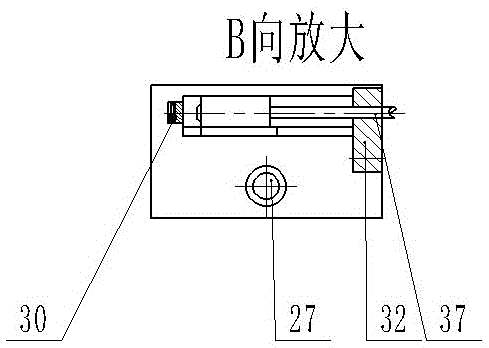

[0021] From figure 1 It can be seen that the automatic half-cutting and bundling device of the reed combine harvester of the present invention includes a reed stalk storage bin and a hydraulic drive system. The bottom plate of the storage bin is composed of a fixed partition and a movable partition. The width of the movable partition is twice that of the fixed partition. The contact edge of the movable partition is also equipped with a pressure sensor to control the sealing of the bottom plate; the two sides of the reed storage bin are symmetrically equipped with 3 pairs of hydraulic support rods and 2 pairs of disc-type baling rods driven by piston rods on the same plane. The half-ring is installed, and a semi-circular auxiliary workbench driven by the piston rod and a corresponding disc-shaped cutter are provided in the middle of the two sides of the reed rod storage bin. The diameter of the disc-shaped cutter is 1.5-2.0 cm larger than the diameter of the reed bundle; All h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com