Improved multistage dual cyclone dust and mist eliminator

A technology of mist eliminator and dust remover, which is applied in the field of flue gas purification, can solve the problems such as the decline of dust removal effect, achieve the effect of improving dust removal effect, reducing fog droplet escape, and strengthening the effect of preventing fog droplet escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

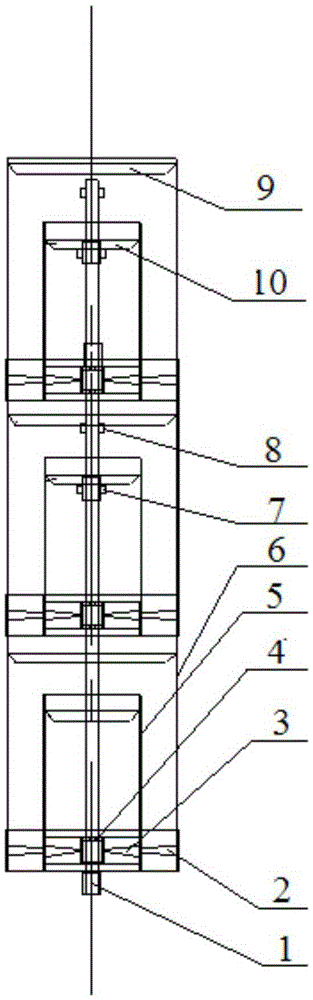

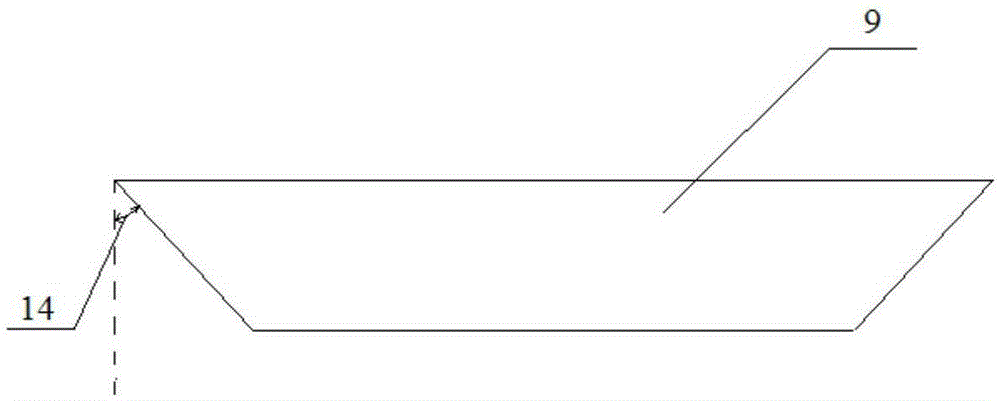

[0026] Such as figure 1 , figure 2 , Figure 4 , Figure 5 As shown, the present invention provides an improved multi-stage double-cyclone dedusting and mist eliminator. The demister and dedusting device 100 includes several double-cyclones arranged inside the outer cyclone cylinder 6, and the double-cyclones include an inner cyclone cylinder 5 , the inside of the inner cyclone 5 is provided with a blind cylinder 4, the inside of the blind cylinder 4 is provided with a flushing water pipe 1, the outer side of the inner cyclone 5 is provided with an outer cyclone blade 2, and the outside of the blind cylinder 4 is provided with an inner cyclone Blades 3, the inside of the inner cyclone 5 is provided with a first flushing nozzle 7 on the flushing water pipe 1, and a second flushing nozzle 8 is provided on the flushing water pipe 1 outside the inner cyclone 5, and the double cyclone is A plurality of multi-stage double cyclones that are connected in series up and down, the in...

Embodiment 2

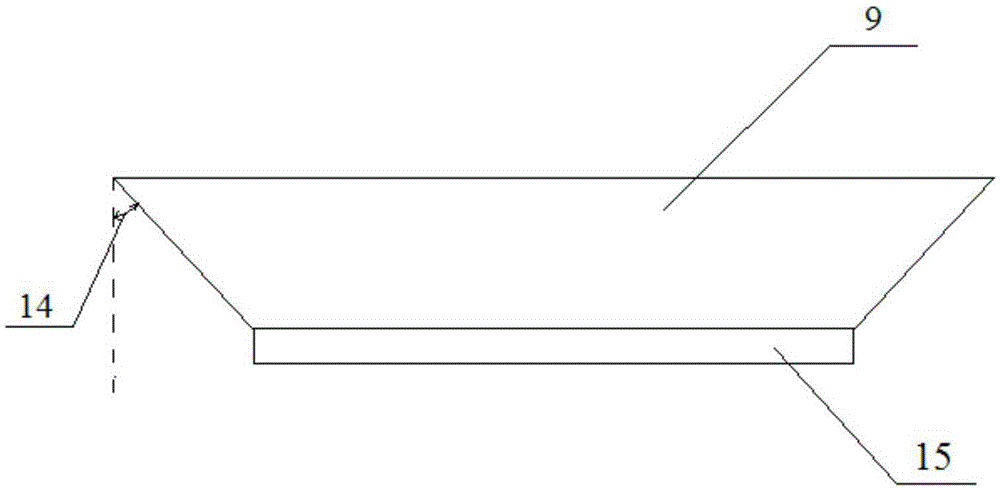

[0036] Such as image 3 As shown, the bottom surface of the first conical ring 9 is connected with a first circular ring 15, and the diameter of the first circular ring 15 is the same as the diameter of the bottom surface of the first conical ring 9; the bottom surface of the second conical ring 10 A second circular ring is connected, the diameter of the second circular ring is the same as the diameter of the bottom surface of the second conical ring 10, and the axis of the first circular ring 15 and the axis of the second circular ring are on the same straight line.

[0037] The height of the first circular ring 15 is 3mm-5mm, and the height of the second circular ring is 2mm-3mm.

[0038] Other than that, other structures are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com