Magnetic separation combination workshop for iron separation from red mud

A technology of red mud and workshop, which is applied in the field of red mud iron separation and magnetic separation combined workshop, which can solve the problems of not fully considering the power consumption of magnetic separation equipment, increasing power loss, and increasing the cable length of magnetic separation equipment, so as to reduce the amount of excavation , saving energy consumption and shortening the cable length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

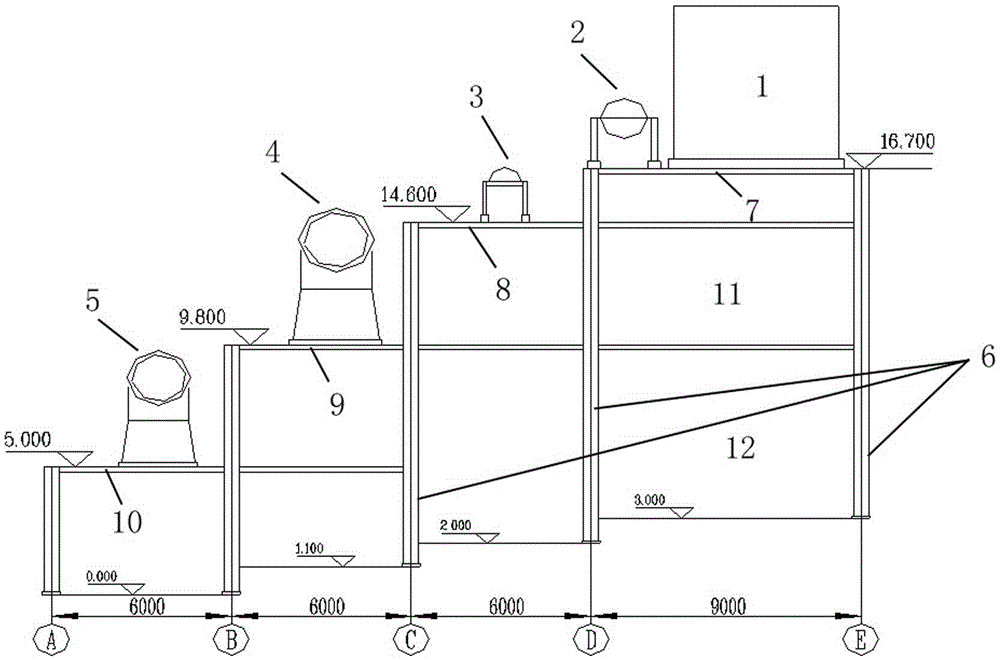

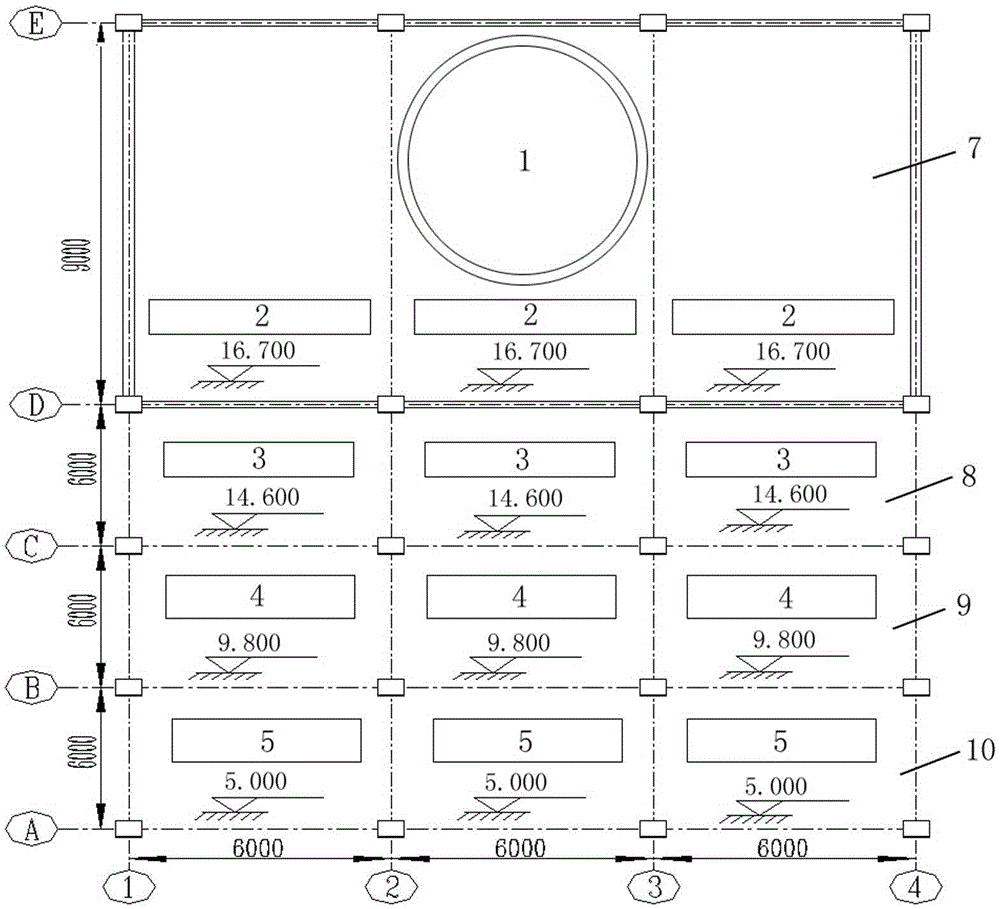

[0015] Embodiment 1: as figure 1 , 2 As shown, a red mud iron and magnetic separation combination workshop includes a stepped platform 6, a red mud mixing tank 1, a cylindrical slag separation screen 2, a cylindrical magnetic separator 3, a coarse magnetic separator 4, and a fine magnetic separator 5. The stepped platform 6 is set in the factory building. The stepped platform 6 is composed of four steps. The first step 10 has an elevation of 5m, the second step 9 has an elevation of 9.8m, and the third step 8 has an elevation of 14.8m. The four-story step 7 has an elevation of 16.7m; taking three production lines as an example: the fourth-floor step 7 is 9m long and 18m wide, the third-floor step 8, the second-floor step 9, and the first-floor step 10 are all 6 meters wide , and the length is 18 meters; in order to improve the land utilization rate and reduce the excavation volume of earthwork: the stepped platform 6 is chosen to be built on the hillside, and it is built acc...

Embodiment 2

[0016] Embodiment 2: as figure 1 , 2 As shown, a red mud iron and magnetic separation combination workshop includes a stepped platform 6, a red mud mixing tank 1, a cylindrical slag separation screen 2, a cylindrical magnetic separator 3, a coarse magnetic separator 4, and a fine magnetic separator 5. The stepped platform 6 is set in the factory building. The stepped platform 6 is composed of four steps. The first step 10 has an elevation of 5.5m, the second step 9 has an elevation of 10.5m, and the third step 8 has an elevation of 15.8m. The fourth step 7 has an elevation of 17.7m; taking 4 production lines as an example: the fourth step 7 is 9m long and 24m wide, the third step 8, the second step 9, and the first step 10 are all 6 in width. meters, and the length is 24 meters; in order to improve the land utilization rate and reduce the excavation volume of earthwork: the stepped platform 6 is selected to be built on the hillside, and it is built according to the slope of ...

Embodiment 3

[0017] Embodiment 3: as figure 1 , 2 As shown, a red mud iron and magnetic separation combination workshop includes a stepped platform 6, a red mud mixing tank 1, a cylindrical slag separation screen 2, a cylindrical magnetic separator 3, a coarse magnetic separator 4, and a fine magnetic separator 5. The stepped platform 6 is set in the factory building. The stepped platform 6 is composed of four steps. The first step 10 has an elevation of 5.3m, the second step 9 has an elevation of 10.2m, and the third step 8 has an elevation of 14.5m. The fourth step 7 has an elevation of 17m; taking 5 production lines as an example: the fourth step 7 is 9m long and 30m wide, the third step 8, the second step 9, and the first step 10 are all 6 meters wide , and the length is 30 meters; in order to improve the land utilization rate and reduce the excavation volume of earthwork: the stepped platform 6 is chosen to be built on the hillside, and it is built according to the slope of the step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com