A consignment trolley used for step-by-step conveying and cleaning of axle housing parts

A step-by-step, axle housing technology, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of large movable space, large lifting range, difficult application, etc., and achieve lightening of the frame Weight, the effect of ensuring bearing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention can be explained in more detail through the following examples. The present invention is not limited to the following examples. The purpose of disclosing the present invention is to protect all changes and improvements within the scope of the present invention.

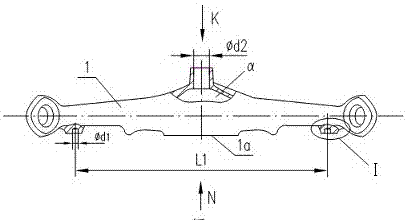

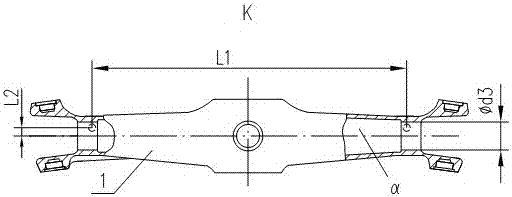

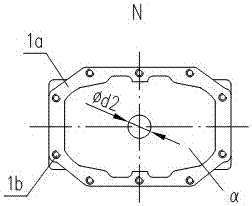

[0064] Depend on Figure 5 to Figure 7 and combine Figure 1 to Figure 4 with Figure 8 to Figure 23 Known, a consignment trolley for step-by-step conveying and cleaning of axle housing parts, comprising positioning pins 2, positioning thin plates 3, car body components 4, flat wheel components 5, V wheel components 6, and bearing components with waterproof seats 7; Two positioning pins 2 are respectively arranged on the mounting concave strips 9 on the left and right sides of the upper part of the vehicle body assembly 4, and are arranged symmetrically on both sides of the second center line β2. In addition, two positioning pins 2 are installed on the upper mounting seat 13 The position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com