Power drive mechanism of multi-freedom-degree mechanical arm

A power-driven, robotic arm technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of uneconomical, increased equipment weight, and high manufacturing costs, and achieve the effect of simplifying the structure and achieving good practical effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

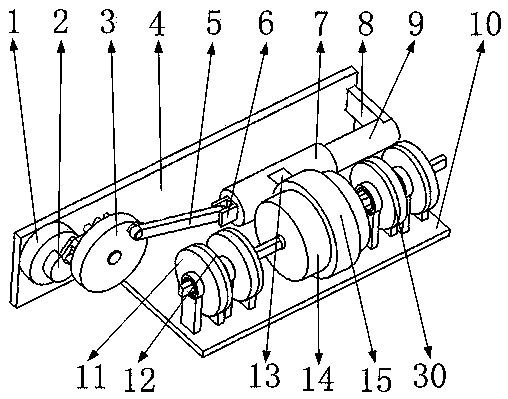

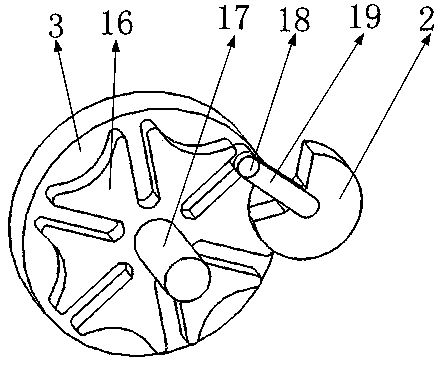

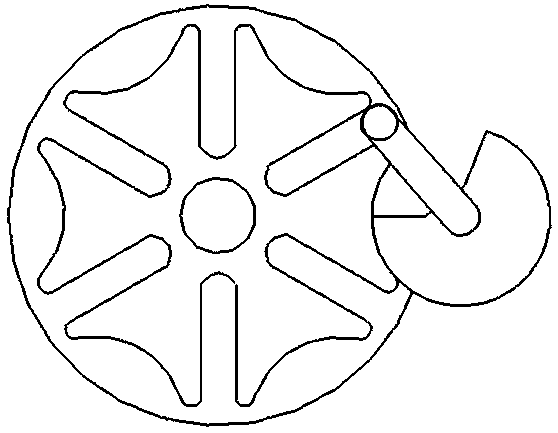

[0036] like figure 1As shown, it includes reciprocating drive motor 1, dial 2, sheave support wheel 3, first support plate 4, rocker 5, first lug 6, sliding sleeve 7, guide rail support 8, guide rail 9, second support Plate 10, gear drive motor support 13, gear drive motor 14, gear drive motor fixing ring 15, gear drive mechanism 30, sheave 16, sheave rotating shaft 17, cylindrical pin 18, rotating arm 19, gear drive motor clamping shaft 28, Conductive block 29, gear drive motor rotating shaft 31, wherein as figure 1 As shown, the reciprocating drive motor 1 is installed on the first support plate 4, as Figure 4 As shown, the dial 2 is installed on the rotating shaft of the reciprocating drive motor 1, as figure 2 , 3 As shown, one end of the rotating arm 19 is installed at the center of the dial 2 and the rotating arm 19 points to the radial direction of the dial 2, the sheave 16 is installed on the sheave support wheel 3, and the sheave 16 is installed on the first shea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com