Welding chassis structure of aerial work platform vehicle

A high-altitude operation and platform truck technology, applied in the direction of lifting devices, etc., can solve the problems of non-removable counterweight, rollover, poor layout and installation of electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

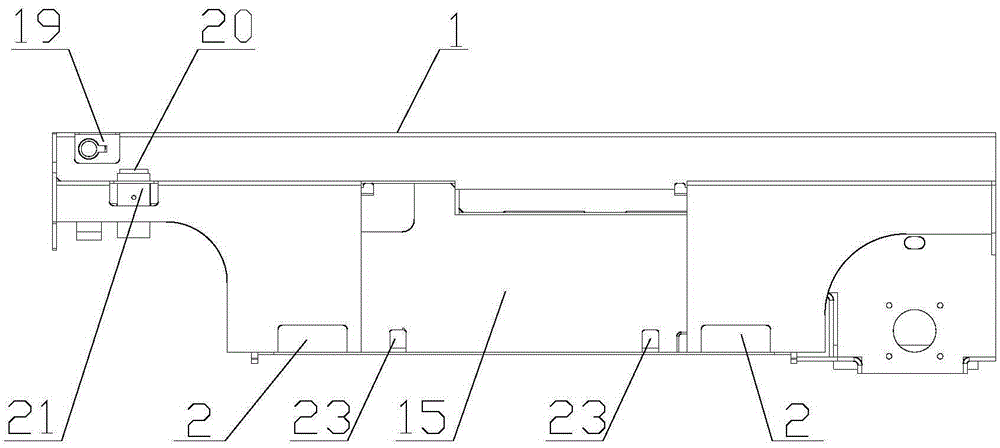

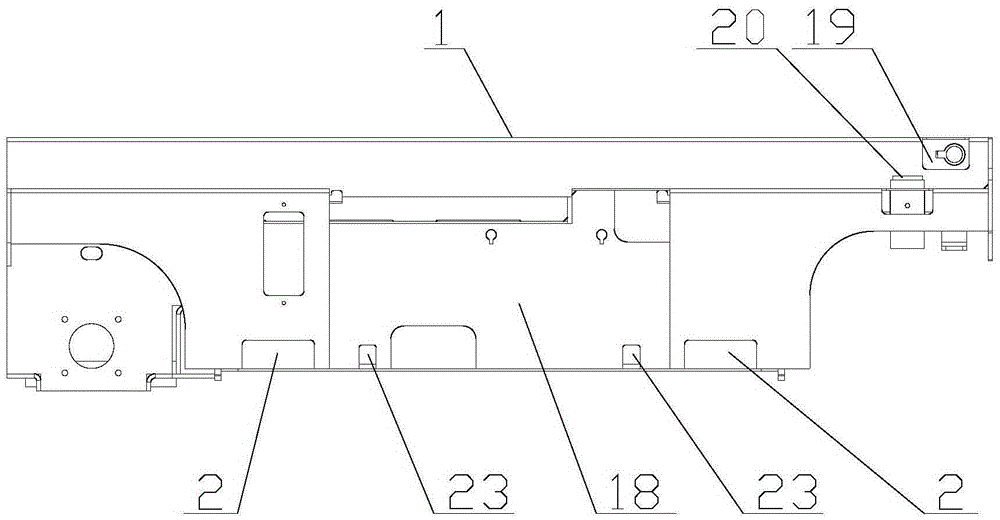

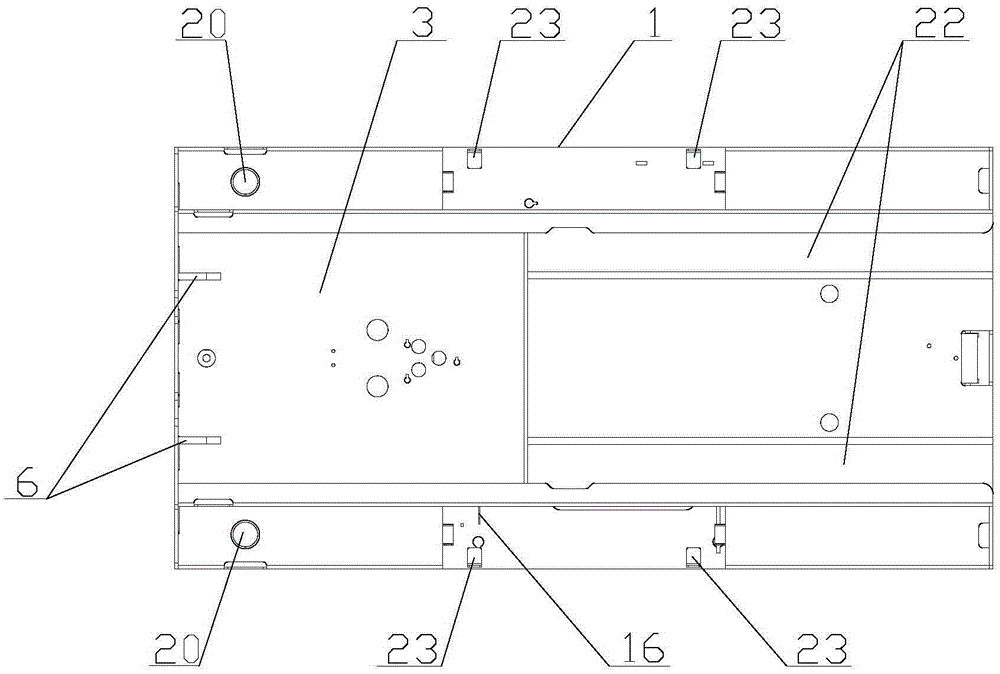

[0026] like Figure 1-8 Provided is a welded chassis structure for an aerial work platform vehicle, comprising a base body 1, one end of the base body 1 is provided with a steering oil cylinder mechanism, the other end of the base body 1 is provided with a counterweight mechanism, and one side of the base body 1 in the length direction is provided There is a battery mechanism, a hydraulic mechanism is provided on the other side of the base body 1 in the length direction, and a forklift hole 2 is provided at the bottom of the base body 1 in the width direction; the steering cylinder mechanism is mainly composed of a cover plate 3, a steering cylinder upper bracket 4, and a steering cylinder. The cylinder lower bracket 5, the fork frame mounting seat 6 and the front guard plate 7 are composed, the front guard plate 7 is fixedly connected to one end of the cover plate 3, the fork frame mounting seat 6 is fixed on the cover plate 3, and the lower bracket 5 of the steering cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com