System for producing heat-insulation and refractory material by using coal gangue calcined material

A technology of refractory materials and calcined materials, which is applied in the direction of textiles, papermaking, glass manufacturing equipment, non-woven fabrics, etc., and can solve the problems of non-containment, non-measurement and cutting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention and its effects will be further described below with reference to the accompanying drawings.

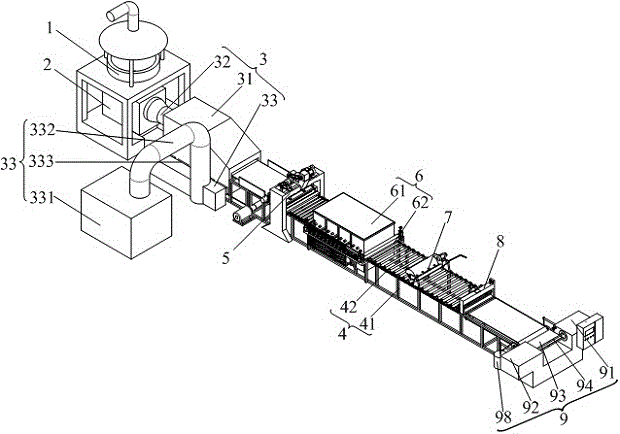

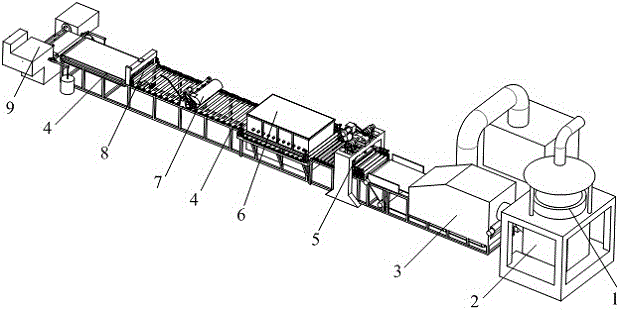

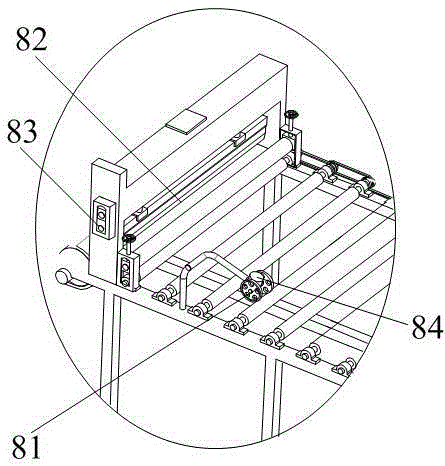

[0018] see figure 1 , figure 2 , a system for producing thermal insulation and refractory materials using coal gangue calcined materials, including furnace equipment 1, silk spinning equipment 2, cotton collection equipment 3, support transmission device 4, acupuncture equipment 5, drying equipment 6, shaping and trimming equipment 7, metering Cutting equipment 8, automatic blanket rolling equipment 9, furnace equipment 1 includes a furnace and a discharge port at the bottom of the furnace, the discharge port is directly above the wire spinning device 2, and the wire spinning device 2 includes a protective cover and a wire spinning machine inside the protective cover , the side wall of the protective cover offers a through hole, and the cotton collecting device 3 includes a cotton collecting cavity 31, a negative pressure chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com