Micro-field emission electric thruster with blade type porous material emitter array

A porous material and electric thruster technology, which is applied in the field of satellite launch, can solve the problems of small effective launch area, small thrust, large thruster size and weight, and achieve high propellant launch density, reduced size and weight, and thrust high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

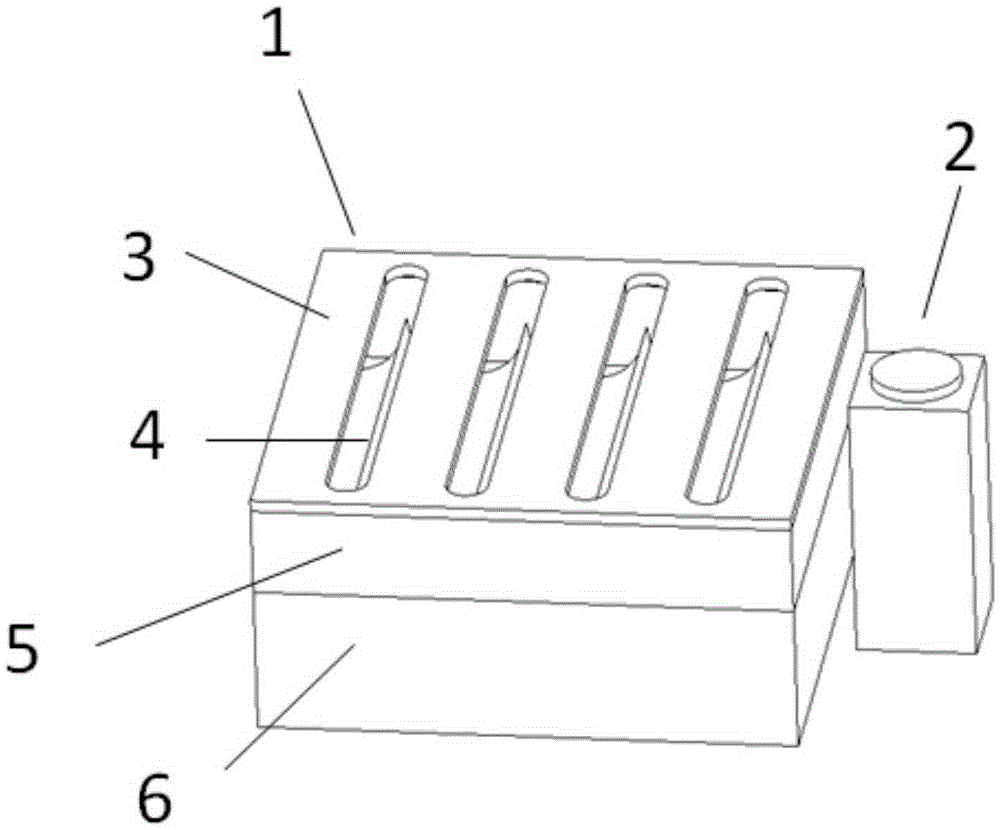

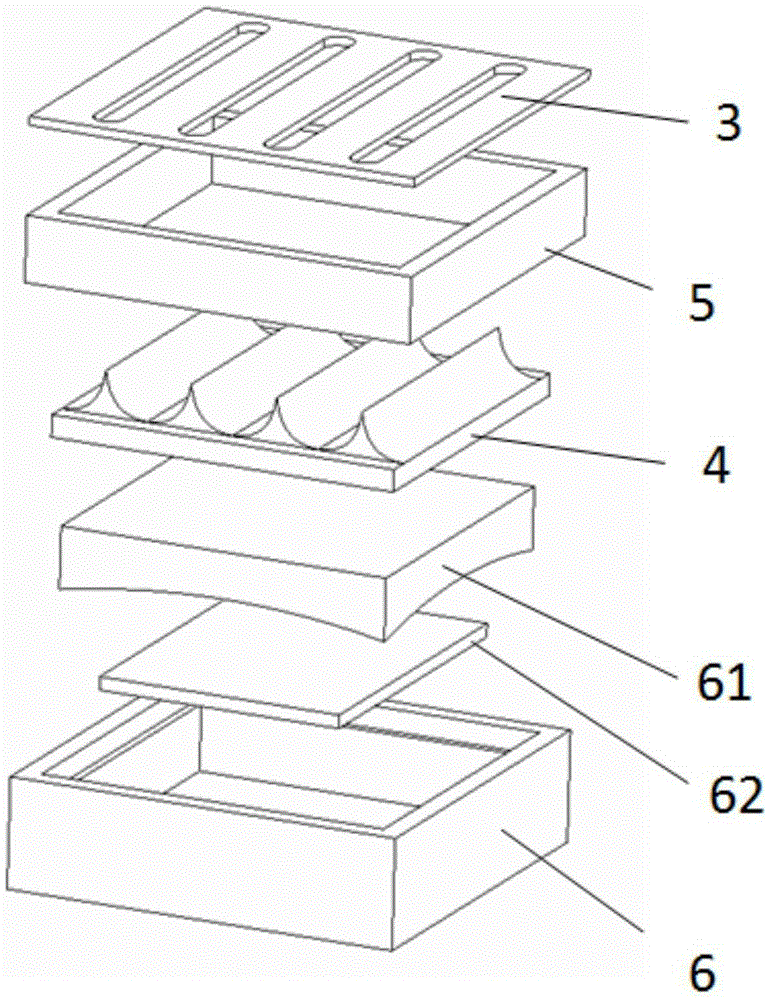

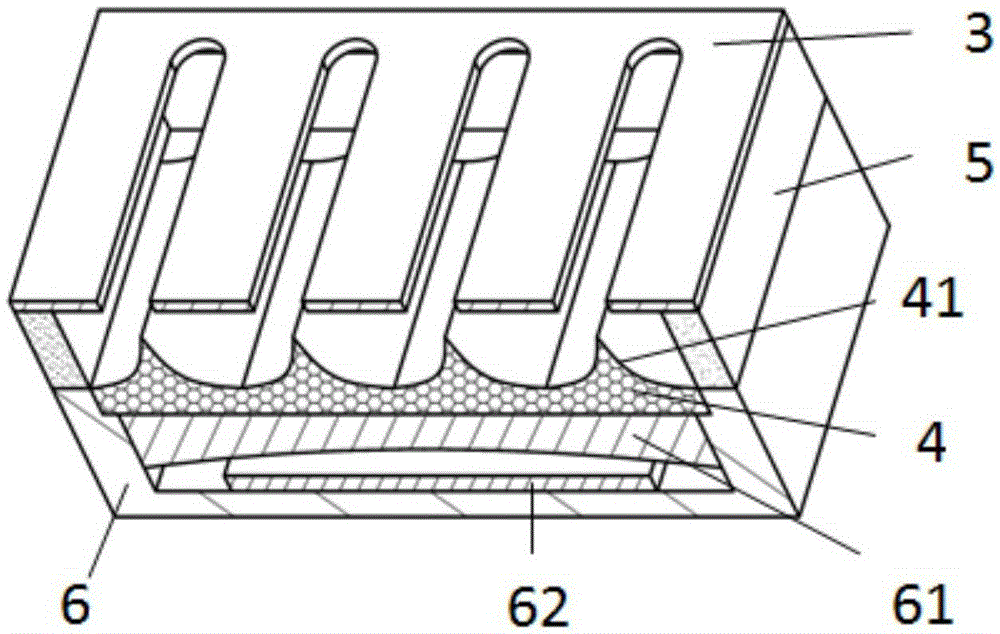

[0031] The present invention provides a kind of blade type porous material emitter array miniature field emission electric thruster aiming at the existing deficiencies, such as figure 1 , figure 2 with image 3 As shown, it includes a neutralizer 2 and a thruster main body 1 connected to each other, the neutralizer 2 emits electrons to neutralize the beam current, and the main body of the thruster 1 includes grids 3 that are mated and connected sequentially from top to bottom , an insulating support 5 and a propellant storage chamber 6, the insulating support 5 is a frame structure, the insulating support 5 is provided with an emitter array 4 matching the grid 3, and the emitter array 4 is provided below Cooperating heater 62 and propellant 61 , the propellant 61 and heater 62 are located in the propellant storage chamber 6 . Wherein, a negative voltage is applied to the gate 3 , the gate 3 has a planar structure, and four gate holes are arranged on the gate 3 .

[0032] W...

Embodiment 2

[0039] The present invention also provides a blade-type porous material emitter array miniature field emission electric thruster, such as Figure 5 As shown, the lower surface of the emitter array is an inner concave surface.

[0040] Other structures in this embodiment are the same as those in Embodiment 1, and will not be described in detail in this embodiment.

Embodiment 3

[0042] The present invention also provides a blade-type porous material emitter array miniature field emission electric thruster, such as Image 6 As shown, the heater 62 is arranged on the lower side of the propellant 61 .

[0043] Other structures in this embodiment are the same as those in Embodiment 1, and will not be described in detail in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com