Measurement apparatus of center position accuracy of all journals of crank shaft, and measurement and calibration methods thereof

A technology for measuring devices and center positions, applied in measuring devices, optical devices, instruments, etc., can solve problems such as expensive, difficult to configure in large quantities, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] A device for measuring the center position of each journal of a crankshaft and a method for measuring and calibrating the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

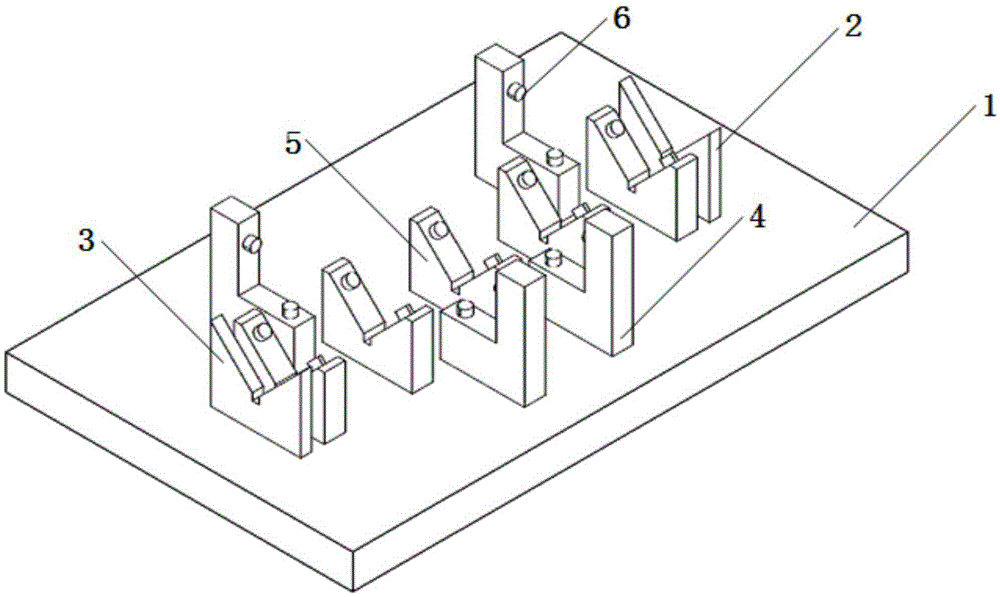

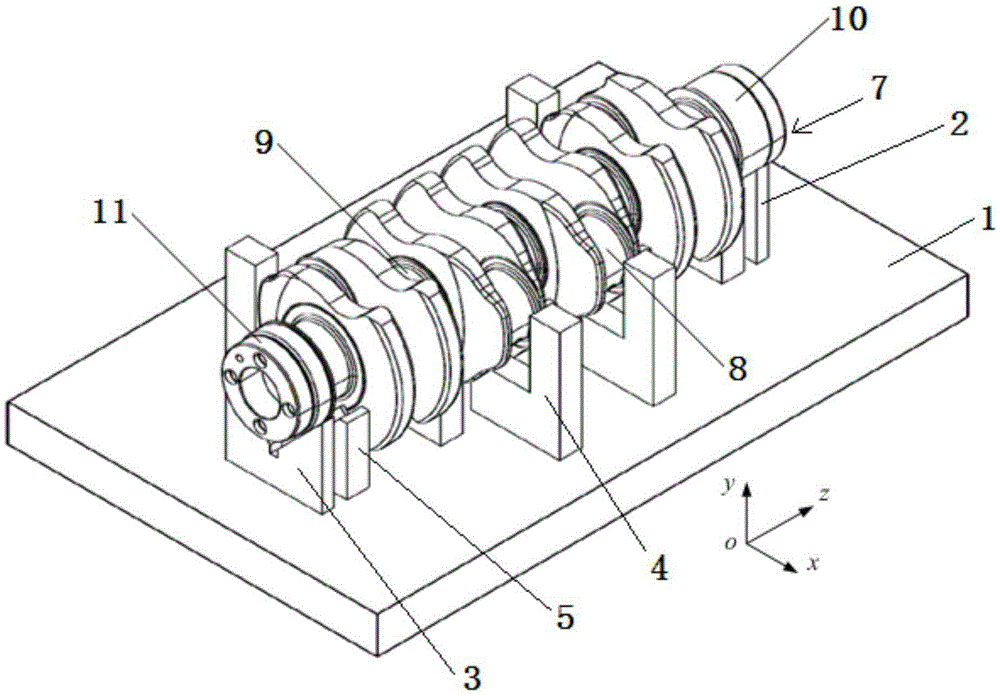

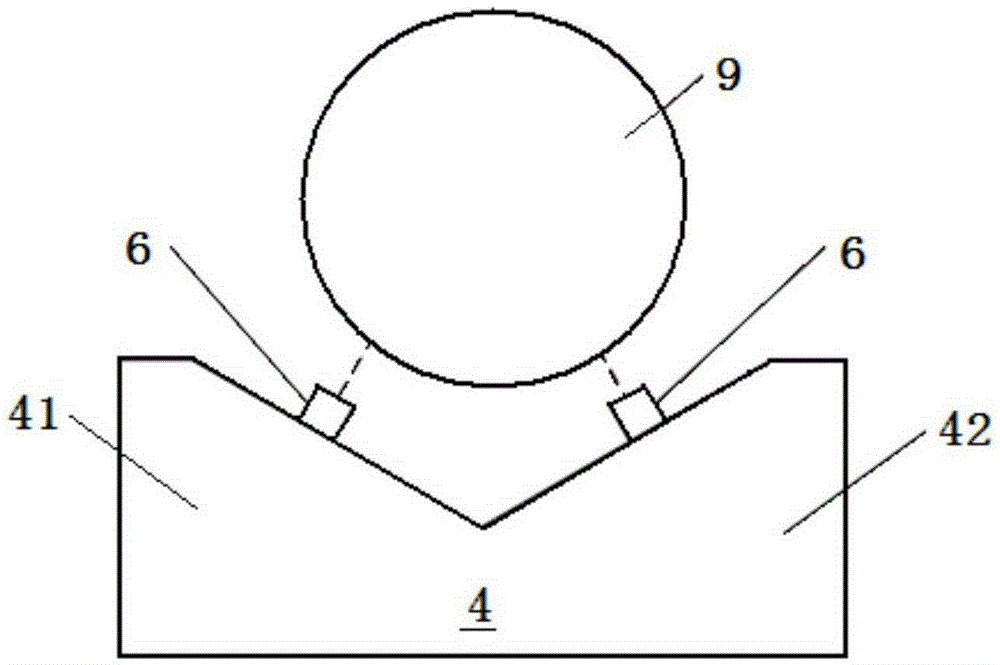

[0056] A device for measuring the center position of each journal of a crankshaft according to the present invention includes a measuring device base 1, and an oil seal journal 11 for supporting the measured crankshaft 7 is arranged on one end of the measuring device base 1 along the length direction. The front neck bracket 3, the other end is symmetrical with the front neck bracket 3 and is provided with a rear neck bracket 3 for supporting the gear journal 10 of the measured crankshaft 7, between the front neck bracket 3 and the rear There are more than 3 main journal measuring frames 5 corresponding to the main journals 9 of the crankshaft 7 to be tested between the neck brackets 2 , 3-17 of which can be set, and are set between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com