Adjustable wire cooling channel

A technology of cooling channels and adjustment lines, applied in the manufacturing of electrical components, circuits, cables/conductors, etc., can solve the problems of difficult adjustment of wind speed, large fluctuations in product quality, economic losses, etc., to ensure stability and flexibility, eliminate Product quality hidden dangers and the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

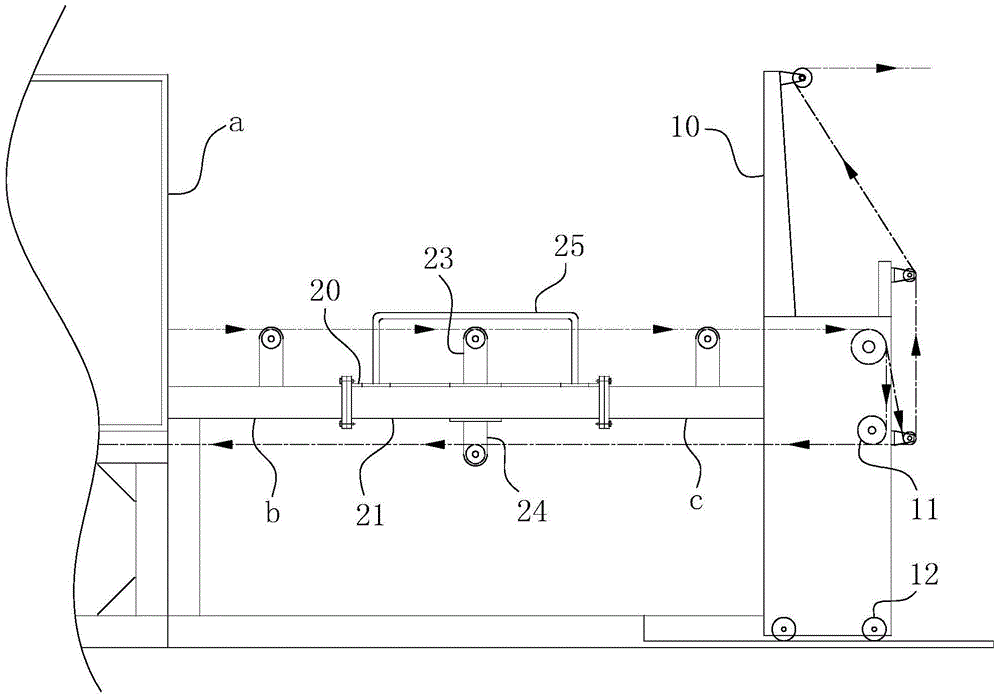

[0024] For ease of understanding, combined here Figure 1-2 Concrete implementation structure and workflow of the present invention are further elaborated as follows:

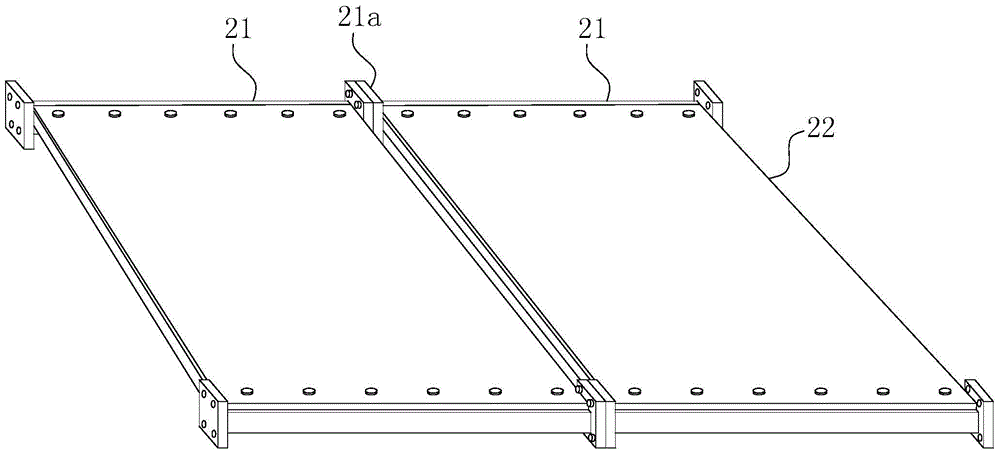

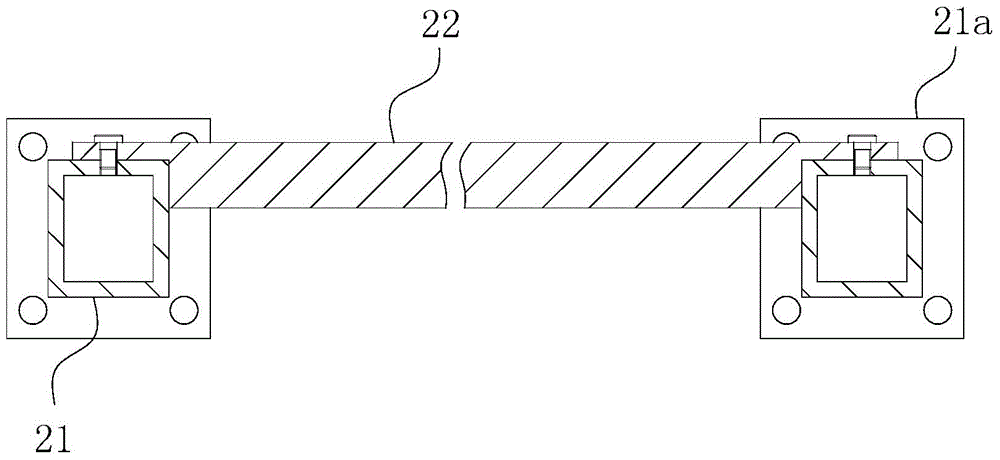

[0025] The implementation structure of the present invention is exemplified by a one-piece horizontal connecting piece for horizontal cooling between the extraction frame 10 and the enamelling furnace a. The overall structure is as figure 1 As shown, it includes the left connecting body b and the right connecting body c extending from the enameled furnace a outlet and the drawing frame 10 at the same height, and the connecting arm 21 of a horizontal connecting piece 20 is connected with the above-mentioned left connecting body respectively. A flange connection is formed between b and the right connecting body c, and the length of the connecting arm 21 is 700 mm. At this time, the isolation plate 22 on the horizontal connector 20 just completely isolates the enameled wire incoming path and the enameled wire re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com